Any successful mezzanine floor installation lives and dies by the quality of the prep work. This is the stage where you move beyond just needing more space and start planning a strategic, functional asset for your facility. It's all about making sure your project starts on a solid foundation—both literally and figuratively.

Laying the Groundwork for Your Mezzanine Project

Before anyone starts talking about design details or material choices, the first real step is a thorough look at your existing space and what you actually need to do with it. Getting this right from the beginning is what stops expensive surprises from cropping up later and ensures the finished structure perfectly matches your business goals. It all comes down to asking the right questions from the get-go.

Understanding Your Building’s Foundation

The single most critical check? The integrity of your building's concrete slab. It’s a simple fact: a mezzanine floor, everything you put on it, and every person who walks on it will concentrate a significant amount of weight onto the ground floor through its support columns. Because of this, confirming your slab’s thickness and load-bearing capacity isn’t just a good idea; it’s a non-negotiable first step.

An experienced mezzanine provider will insist on a site survey to evaluate this. Often, this involves taking core samples to verify the concrete's depth and strength. Overlooking this detail can lead to catastrophic structural failure, which makes it the most important piece of due diligence you’ll undertake.

Defining the Mezzanine’s Purpose

Once you're confident the ground can take the weight, you need to get crystal clear on what the structure will be used for. This one decision will dictate every single choice that follows, from the load rating to the type of decking you install.

- Lightweight Storage: Are you just storing archived documents or small, hand-loaded inventory? This typically calls for a standard load capacity, often around 3.5 kilonewtons per square metre (kN/m²).

- Heavy-Duty Operations: Will the floor need to support heavy machinery, pallet trucks, or high-density shelving? This demands a much higher load rating—we could be talking 10 kN/m² or more—which completely changes the steelwork specification.

- Office or Production Space: If you’re planning to put offices or a production line up there, the design has to account for fire safety regulations, employee welfare facilities, and the specific workflow you need.

A common mistake we see is people under-specifying the load capacity to save a bit of money upfront. A floor designed for light storage simply can’t be repurposed for heavy equipment later without major—and very expensive—re-engineering. Always plan for your most demanding potential use case.

This kind of careful planning is more important than ever. The UK's demand for warehouse space is soaring, thanks in large part to the e-commerce boom. According to the Office for National Statistics (ONS), the number of UK business premises classified for storage and transport shot up by 88% between 2011 and 2021. This is putting huge pressure on facilities to get more out of the space they already have. You can read more about designing future-proof mezzanines and see how your project fits into this growing trend.

Conducting a Comprehensive Site Survey

Beyond just the concrete slab, a detailed site survey is essential for spotting any potential obstacles that could throw a spanner in the works during the installation. An expert will walk the site, mapping out the precise locations of everything that could get in the way:

- Existing Building Columns: These aren't going anywhere, so they must be integrated into the mezzanine's own column grid.

- Utility Lines: It's amazing how often people overlook electrical conduits, plumbing, or HVAC ducting. Finding these late in the game leads to expensive relocations.

- Access Points: How will goods and people get on and off the mezzanine? The location of loading bay doors and main walkways will determine where staircases and pallet gates need to go.

- Clear Height: Measuring the available vertical space is crucial. You have to ensure there's enough headroom both above and below the new floor to comply with safety regulations.

This survey ultimately becomes the blueprint for a realistic and efficient design. It ensures the new structure slots seamlessly into your existing building layout instead of fighting against it. Getting these fundamentals right is what makes a project run smoothly from concept to completion.

Navigating UK Building Regulations and Compliance

Getting the physical build of a meзоanine floor right is only half the battle. The other half—successfully navigating the legal landscape—is just as important. While you generally won’t need full planning permission for an internal mezzanine, Building Regulations Approval is almost always mandatory here in the UK.

This isn't just about ticking boxes; it's a critical process designed to ensure your new structure is safe, accessible, and genuinely fit for purpose.

Treating compliance as an afterthought is a costly mistake. I've seen it lead to massive delays and, in the worst cases, even orders to dismantle a brand-new structure. The smartest move you can make is to engage with your mezzanine supplier and a structural engineer right from the very beginning. They'll guide you through your local authority's requirements and make sure the design is compliant from day one.

Understanding Fire Safety Requirements

Fire safety is, without a doubt, the most critical piece of the Building Regulations puzzle for mezzanine floors. The rules aren't one-size-fits-all; they shift quite a bit depending on how you plan to use the space, its size, and where it sits within your building.

A major factor here is travel distance—the furthest anyone would need to walk to get to a protected escape route or a final exit. If your new mezzanine extends these travel distances beyond the legal limits, you’ll need to put other safety measures in place to compensate.

Here’s a quick look at common fire protection rules:

- Small, Ancillary Use: If the mezzanine is small (often under 10m in any direction and covering no more than 50% of the room's area) and just used for light storage with few people around, you might not need to fire rate it.

- Larger Structures or Public Access: For bigger floors, or those used as offices or areas open to the public, a 60-minute fire rating is usually the standard. This means cladding the underside of the floor and all supporting columns with fire-resistant materials.

- Escape Routes: The structure absolutely cannot block existing escape routes. You’ll need to create clearly defined, protected escape paths from the mezzanine level itself, which often means installing more than one staircase.

Accessibility and Structural Integrity

Beyond fire safety, your design has to follow strict rules for accessibility and structural soundness. This is where professional, detailed plans and calculations are non-negotiable. An approved inspector or local authority building control officer will need to see clear proof that you've met these standards.

For instance, the design of your staircases is heavily regulated. The pitch, tread depth, and riser height all have to comply with Approved Document K of the Building Regulations, which covers protection from falling, collision, and impact.

Don't underestimate the details. Something as seemingly minor as the handrail specification or the inclusion of tactile paving at the top and bottom of stairs can be the difference between approval and rejection. A compliant design considers every element from the outset.

Your submission to the local authority has to be robust and detailed, proving the structure's safety from every angle. To get a handle on all the specific rules that might apply, it's worth learning more about the complete list of Building Regulations that govern these projects. It’ll ensure you're fully prepared for the approval process.

The Essential Documentation for Approval

You can't just show up with a basic sketch to get Building Regulations Approval. You need to submit a comprehensive pack of technical documents for review. This is where a partnership with a specialist supplier really pays off, as they will typically handle the heavy lifting of preparing this package for you.

Here are the key documents you’ll almost certainly need:

- General Arrangement Drawings: These are detailed plans showing the mezzanine's layout, dimensions, and exact position within the building. They'll map out access points, column locations, and escape routes.

- Structural Calculations: A qualified structural engineer prepares these to prove the design can safely handle its intended load. This covers the weight of the structure itself plus the live load (people, stock, equipment).

- Detailed Designs: This includes the nitty-gritty specifics for crucial components like staircases, handrailing, and connections, showing they meet all relevant British Standards and building codes.

Submitting a complete and accurate application is the secret to a smooth process. Missing information or non-compliant designs are the biggest culprits for delays, pushing back your project timeline and adding to your costs. Get it right the first time, and you’ll keep your project on track and meet every legal requirement for a safe, functional installation.

Designing Your Mezzanine for Peak Performance

A truly effective mezzanine is far more than just an elevated platform; it's a strategic asset designed to actively improve your workflow. Smart design is what transforms that raw extra square footage into a genuine productivity engine. The decisions made at this stage will directly impact how efficiently your team and goods move around your facility for years to come.

This design phase is where we translate the practical needs we identified during the initial groundwork into a physical structure. It’s all about creating a floor that doesn't just fit into your building but seamlessly integrates with your daily operations, making everything smoother and more efficient.

Optimising the Column Layout

One of the first—and most critical—design decisions is getting the column grid right. The goal here is to strike the perfect balance: maximising the clear, open space on the new level while causing the least possible disruption to the workflow on the ground floor below.

A poorly placed column can create a permanent bottleneck for forklift traffic or block access to essential machinery. An experienced designer will analyse your ground-floor layout—taking into account machinery footprints, key walkways, and vehicle routes—to position support columns in the least intrusive spots. Sometimes this means aligning them with existing building pillars or tucking them into dead zones between workstations.

This thoughtful approach ensures the new structure enhances your space without creating new operational headaches.

Planning for Seamless Flow and Access

How will people and materials actually get onto and off the mezzanine? The answer to this question defines the flow of your entire operation. The placement of staircases and pallet gates isn't an afterthought; it’s a crucial element of a high-performance design.

Staircases should be located to provide quick and safe access for staff without forcing them to take long, inefficient routes. In a self-storage facility, for instance, positioning a staircase near the main entrance gives customers easy access to upper-level units.

Likewise, pallet gates must be strategically placed to align with your primary goods-in and goods-out zones. A common and effective setup involves positioning a pallet gate directly above a main ground-floor aisle. This allows a forklift operator to safely lift and deposit goods without any complex or time-consuming manoeuvring.

A well-designed mezzanine directs traffic, it doesn't obstruct it. Think of staircases and gates as the arteries of your vertical space. Placing them correctly ensures a smooth, uninterrupted pulse of activity throughout your facility.

Matching Load Capacity to Your Needs

Not all mezzanines are created equal, and the biggest differentiator is their load-bearing capacity. This metric, measured in kilonewtons per square metre (kN/m²), dictates everything from the thickness of the steelwork and the spacing of the support columns to the type of decking you'll need.

- Light Storage (3.5 – 5.0 kN/m²): Ideal for storing archived documents, hand-loaded small parts, or areas with light foot traffic. This calls for a standard, cost-effective steel frame.

- General Production (5.0 – 7.5 kN/m²): Suitable for supporting some light machinery, assembly lines, or medium-duty shelving systems.

- Heavy-Duty Storage (7.5+ kN/m²): Essential for high-density shelving, pallet truck usage, or supporting heavy equipment. This requires a much more robust steel structure and thicker decking.

Choosing the correct load rating is crucial. If you under-specify, you create a serious safety hazard. But if you over-specify, you’re simply paying for steel you don’t need. For a detailed look at options for business use, you can explore our guide to commercial mezzanine floors.

The growing demand for these structures reflects wider industrial trends. In 2025, the UK mezzanine floor market is projected to see a Compound Annual Growth Rate (CAGR) of around 5.7%. This steady growth is part of a global market forecast to be worth approximately USD 8.8 billion and is driven by innovations making installations more feasible, even in older buildings.

Choosing the Right Decking Material

The floor surface, or decking, is the final piece of the structural puzzle. What you choose depends entirely on the mezzanine's intended use, and it's always a balance between durability, cost, and functionality.

To make it easier, here's a quick rundown of the most common options we work with.

Choosing the Right Mezzanine Decking Material

| Decking Material | Best For | Key Advantages | Considerations |

|---|---|---|---|

| 38mm Particle Board | General storage, light production, and office areas. The most common choice. | Cost-effective, smooth surface, and easy to install. | Not suitable for wet environments or very heavy point loads. |

| Durbar / Chequer Plate | Industrial environments, heavy-duty walkways, and areas with trolley use. | Extremely durable, excellent slip resistance, and protects against impacts. | Can be noisy and more expensive than particle board. |

| Composite Decking | High-end office spaces, retail showrooms, or areas requiring a polished finish. | Aesthetically pleasing, excellent fire resistance, and feels solid underfoot. | Higher initial cost and heavier than other options. |

By carefully considering each of these design elements—from the column grid right through to the final floor finish—you ensure your mezzanine floor installation isn't just an addition, but a powerful upgrade to your entire operational capacity.

What to Expect During the Installation Process

Once the design gets the final nod and the materials arrive on site, the project shifts from paper plans to physical construction. This is the exciting part where your vision really starts coming together. Knowing the sequence of events is key to managing your expectations and making sure the whole me-zzanine floor installation runs like clockwork. A professional crew will follow a precise, well-practised process to get the structure up safely and efficiently.

The entire process is carefully managed to keep disruption to a bare minimum. Your project manager will be your main point of contact, coordinating the on-site team and keeping you in the loop on progress. Clear and consistent updates are the hallmark of a well-run installation, ensuring everyone is on the same page from day one.

Site Preparation and Safety First

Before a single piece of steel is lifted, the number one priority is setting up a safe and secure work zone. This is a non-negotiable step that protects both the installation crew and your own staff. The designated area will be cordoned off with safety barriers and clear signage to keep unauthorised people out.

It's really important to coordinate with the installation team to manage any impact on your day-to-day operations. For instance, if the work zone temporarily blocks a key access route, you'll need to establish a clear alternative path and communicate it to your staff. A bit of proactive planning here prevents workflow bottlenecks and keeps everyone safe.

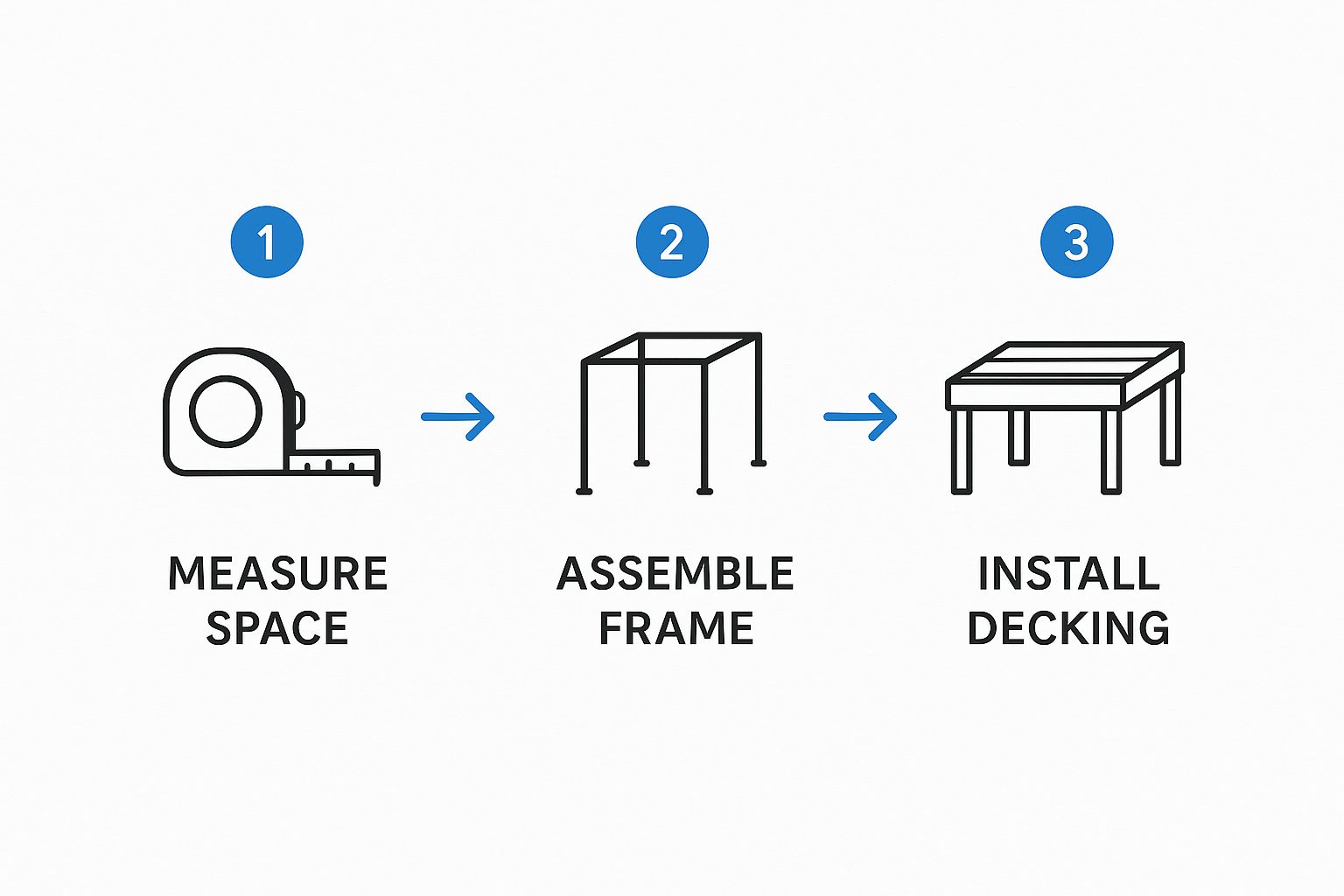

This brief infographic gives a high-level overview of the main construction steps.

As you can see, the build follows a logical flow, starting from the foundations and working up to the finished walking surface.

Erecting the Steel Superstructure

With the site secure, the installation begins in earnest. The team builds the structure from the ground up, with precision being the name of the game at every stage.

-

Marking and Setting Column Bases: First, the crew accurately marks out the column positions on the concrete slab, following the approved design drawings to the millimetre. Base plates are then fixed securely to the floor, creating the solid foundation for the entire structure.

-

Lifting the Main Frame: Next, the vertical columns are lifted into place and bolted to the base plates. The main support beams are then carefully raised and connected to the columns, forming the primary skeleton of the mezzanine. This is a critical phase that requires skilled operatives and specialised lifting gear to ensure every component is perfectly aligned.

-

Installing Secondary Joists: With the main frame standing tall and stable, the smaller secondary joists (often called purlins) are installed. These run perpendicular to the main beams and create the support system for the decking. Their spacing is precisely calculated to handle the load capacity and match the decking type specified in your design.

The speed and efficiency at this stage can be genuinely surprising. A well-prepared team can often get the entire steel frame for a medium-sized mezzanine erected in just a couple of days. That rapid progress is a direct result of detailed planning and all the pre-fabrication work done off-site.

The meticulous approach taken here is vital for the structural integrity of the entire build. To see how expert teams handle this, you can learn more about the complete manufacture and installation process, which really highlights the importance of quality control from the factory floor to the final bolt.

Completing the Floor and Ancillaries

Once the steel superstructure is in place, the focus shifts to creating the functional floor surface and adding all the finishing touches. This is where the mezzanine transforms from a steel skeleton into a proper, usable space.

The first job is laying the decking. Whether it's 38mm particle board or heavy-duty steel chequer plate, each panel is carefully laid onto the joists and fixed securely in place. This creates a solid, stable platform ready for whatever you need it for.

After the main decking is down, the team moves on to fitting all the ancillary components. This is the final stage of the main construction and includes:

- Staircases: These are carefully positioned and fixed to both the mezzanine and the ground floor, providing safe and compliant access.

- Handrailing and Edge Protection: Safety is absolutely paramount. Handrails are installed around all exposed edges of the mezzanine, including the staircases, to prevent any falls.

- Pallet Gates: If they're part of your design, pallet gates are fitted in their designated spots, allowing for the safe transfer of goods between levels.

After everything is installed, a final inspection is carried out. The project manager will walk the site with you to ensure every last detail meets the agreed-upon specification and quality standards. Only when you are completely satisfied is the project considered complete and ready for handover. This thorough commissioning process guarantees you get a safe, compliant, and high-performance mezzanine floor installation.

Future-Proofing Your Mezzanine Investment

A mezzanine floor installation isn’t just a quick fix for a space shortage; it’s a major capital investment. To get the most out of it, you have to think beyond your immediate needs. How might your business look in five, ten, or even fifteen years? Making smart, forward-thinking decisions right now ensures your mezzanine grows with you, becoming a valuable asset rather than a structural headache down the line.

It’s about shifting from a "what do I need today?" mindset to asking, "what could I need tomorrow?". This simple change in perspective turns your new floor from a static platform into a strategic part of your long-term plan, ready for new processes, technologies, and whatever the market throws at you.

Designing for Adaptability and Growth

One of the best ways to future-proof your investment is to build adaptability in from the very beginning. A common mistake we see is specifying a load capacity that just meets current requirements. It might shave a little off the initial steelwork cost, but it can be incredibly restrictive later on.

Imagine your operation today is all about storing lightweight, hand-picked stock. A standard 5.0 kN/m² floor seems perfectly fine. But what happens in three years when you bring in heavier automated picking machinery or decide to store dense, palletised goods? Suddenly, that floor is a liability.

By specifying a higher load capacity from the start—say, 7.5 kN/m²—you build in crucial flexibility. The slightly higher upfront cost is tiny compared to the expense and disruption of reinforcing or completely replacing the structure later. This one decision keeps your options open for heavier machinery, different storage configurations, or entirely new operational workflows.

Think of it like this: you're not just buying floor space; you're investing in operational agility. Building in extra load capacity is a small premium to pay for the freedom to pivot your business strategy without being held back by your own infrastructure.

If you're planning a new build, exploring innovative mezzanine floor designs to optimise your self-storage space can spark some great ideas on maximising flexibility right from the get-go. This kind of forward planning makes sure the mezzanine supports your future ambitions, rather than getting in their way.

Integrating Technology from Day One

The future of warehousing and logistics is undeniably driven by technology. Your new mezzanine needs to be ready for this shift, not resistant to it. Thinking about tech integration during the initial design is a powerful way to future-proof your investment and stay ahead of the curve.

This can be as simple as planning for cable management and power distribution. Think about including conduits and enough power outlets to support future systems you might not even be considering yet.

Here’s what to keep in mind:

- Conveyor Systems: A structure that’s already designed to handle the weight and fixing points for conveyors makes a future automation project far simpler and cheaper.

- Automated Storage and Retrieval Systems (AS/RS): These systems have very specific structural and dimensional needs. Factoring them into your column grid and floor height now can save a fortune in retrofitting costs.

- Smart Sensors: Planning for IoT-based sensors to monitor structural health, usage patterns, or environmental conditions can improve safety and pave the way for predictive maintenance.

This proactive approach is more important than ever as the UK market embraces automation. The rise of robotics and smart systems in warehouses requires mezzanines that can support these upgrades without a complete overhaul. With the global mezzanine floor industry forecast to grow at a CAGR above 7% through 2030, and the UK adopting smart building solutions, planning for technology today ensures your mezzanine remains a relevant and productive asset for years to come.

Your Top Mezzanine Questions Answered

Even the most meticulously planned project comes with questions. When it comes to something as significant as a new mezzanine floor, it's completely normal to have a few things you want to clarify before work begins. Getting these common queries out of the way early helps align everyone, from your own team to the installers on the ground.

We get asked these questions all the time, so we've put together some straightforward answers to help you navigate the final steps of your decision with confidence. Think of this as your cheat sheet for avoiding surprises down the line.

How Long Does a Mezzanine Installation Take?

This is a big one. The on-site build is often much quicker than people imagine, but that's just one piece of the puzzle. A small, simple mezzanine going into an empty warehouse might only take a couple of days to put up. On the flip side, a large, multi-tier structure in a busy, fully operational facility could take several weeks of careful, phased work.

From your first phone call to the final handover, the entire journey typically takes between 6 to 12 weeks. Here’s a rough breakdown of how that time is spent:

- Design & Survey: Allow 2–4 weeks for us to conduct site surveys, hash out the details in consultations, and get the technical drawings finalised.

- Fabrication: The steelwork then needs to be manufactured, painted, and prepped for delivery, which usually takes 3–5 weeks.

- On-Site Build: An average-sized floor can be erected in 1–2 weeks, though this really depends on the complexity.

It's crucial not to forget about Building Regulations approval. This is an administrative step that can add several weeks to your schedule before any physical work can start. Always build this time into your project plan to avoid any frustrating delays.

Do I Need Planning Permission for a Mezzanine?

This is probably the most common point of confusion we see. The short answer is: in most cases in the UK, you do not need planning permission for a mezzanine floor. Because it’s seen as a demountable, internal structure, it doesn’t change the building's external look or its footprint, which is what planning permission is all about.

However, what you almost certainly will need is Building Regulations Approval. This is a completely different process that focuses on ensuring the new structure is safe, accessible, and compliant with all the relevant fire codes.

There are exceptions, of course. Planning permission might be required if the mezzanine significantly increases your retail floor space or alters the building's designated use class. If you're ever in doubt, your best bet is to have a quick chat with your local authority or a mezzanine specialist.

What Is the Average Cost of a Mezzanine Floor?

Trying to pin down an "average" cost is tough because every single mezzanine installation is bespoke. The price is always quoted per square metre, but that figure can shift based on a handful of key variables.

As a rough guide, you could be looking at a range from around £80 per square metre for a basic storage platform, all the way up to £250+ per square metre for a high-spec office floor complete with full fire rating, suspended ceilings, and premium finishes.

The main things that will drive your final cost include:

- Total floor area: As you'd expect, bigger floors generally have a lower cost per square metre.

- Load capacity: A floor designed to hold heavy machinery will need a lot more steel (and therefore cost more) than one built for light storage.

- Column grid: The further apart the support columns are, the heavier the steel beams need to be, which pushes the price up.

- Ancillaries: The number and type of staircases, the style of handrailing, and whether you need pallet gates all add to the final figure.

Always insist on a detailed, itemised quotation. It’s the only way to see exactly where your money is going and to compare different proposals on a like-for-like basis. A transparent quote is your best defence against hidden costs and ensures you're making a fully informed decision.

Ready to transform your unused vertical space into a valuable asset? The team at Partitioning Services Limited has over two decades of experience in designing and delivering bespoke mezzanine solutions. Contact us today for a no-obligation consultation and find out how we can maximise your facility's potential.

Looking for help with your next project?

Whether you are new to self storage or already have an established self storage facility, we can provide you with guidance and a full quotation for any aspect of your works.