A racking safety inspection is more than just a box-ticking exercise. It’s a thorough, expert-led evaluation of your warehouse storage systems, designed to spot damage, confirm structural integrity, and keep you compliant with safety laws. In short, it’s a non-negotiable process that protects your people, your products, and your entire operation from the very real risk of rack failure.

Why Racking Safety Inspections Are a Legal and Operational Must

It’s easy to think of pallet racking as static furniture, but that’s a dangerous mistake. These structures are dynamic pieces of work equipment, constantly dealing with heavy machinery, changing loads, and human interaction. This constant stress makes them prime candidates for wear and tear, damage, and eventually, collapse if they’re not looked after.

Getting your head around the basics of what is preventive maintenance really hammers home why regular racking inspections are absolutely essential. It’s all about being proactive—catching the small problems before they spiral into something far more dangerous and costly.

Your Legal Responsibilities in the UK

In the UK, keeping your racking safe isn't just good advice; it's the law. These obligations are laid out very clearly to protect employees and ensure a safe working environment for everyone in your facility.

The main piece of legislation you need to know is The Provision and Use of Work Equipment Regulations 1998 (PUWER). This is a big one for warehouse operators. It states that any equipment provided for work, and that includes pallet racking, must be:

- Suitable for its intended use.

- Safe for use, maintained in a safe condition, and inspected.

- Used only by people who have received adequate training.

- Accompanied by suitable safety measures, such as protective devices and controls.

Specifically, Regulation 6 of PUWER requires that racking systems are inspected when first installed, after being reassembled, whenever damage is suspected, and at least once a year by a technically competent person.

A "technically competent person" isn't just anyone. It's someone with the specialised knowledge and hands-on experience to identify faults and accurately assess how serious they are. This is precisely why so many businesses bring in a SEMA Approved Racking Inspector (SARI) for their annual checks. They provide an unbiased, expert assessment that ticks all the legal boxes.

Creating a Proactive Safety Culture

While the annual expert inspection is a legal must-have, it should never be the only time your racking gets checked. A truly effective safety system combines these formal audits with a continuous, internal culture of watchfulness.

This means empowering your own team to be the first line of defence. Simple daily or weekly visual checks by trained warehouse staff can catch new damage—a dented upright from a forklift knock, a dislodged beam, or a missing locking pin—long before the annual inspector is due.

When your people know what to look for and feel they can report issues without facing blame, you create a powerful, proactive safety net. It’s a culture that protects your most valuable assets: your staff and the continuity of your business.

How to Prepare for a Smooth Inspection

A successful racking safety inspection doesn't just happen on the day. The real work begins long before the inspector walks through your door, and a bit of prep goes a long way. Getting organised beforehand makes the whole thing run smoother, keeps disruption to a minimum, and shows a genuine commitment to safety.

The aim is simple: give the inspector clear, unobstructed access and all the information they need. This involves sorting out both the physical environment and the necessary paperwork. Think of it as a productive audit, not a disruptive fault-finding mission.

Assemble Your Documentation

First things first, get your paperwork in order. This is a crucial step. Your inspector needs to see key records to piece together your racking's history, its specifications, and how it’s been maintained.

Before the visit, make sure you can easily pull out the following:

- Previous Inspection Reports: These are essential. They provide a clear history of past issues and the repairs that were carried out.

- Maintenance Logs: Any documentation detailing repairs or component replacements is vital for showing proactive upkeep.

- Load Capacity Notices: Double-check that these are clearly visible on the racking and are accurate for the current configuration.

- Original Layout Drawings: If you have them, these are gold. They help the inspector understand the system's intended design from day one.

For larger sites, managing all this can feel like a mammoth task. This is where effective https://psllimited.co.uk/storage-facility-project-management comes in. Having a central, organised system for these records makes retrieval for audits or even day-to-day reference a breeze.

Prepare the Warehouse Floor

Once your documents are ready, it’s time to prep the physical space. The inspector needs to get up close and personal with every part of your racking, from the base plates right up to the highest beams.

Clear communication with your team is key here. Let everyone know when and where the inspection will take place. This ensures they can help keep aisles clear of pallets, machinery, or any other debris that might get in the way.

It sounds simple, but this bit of housekeeping is what prevents delays and the headache of having to reschedule.

The Health and Safety Executive (HSE) also stresses the importance of a tidy, organised warehouse environment. It's fundamental to safety.

This isn’t just about looking good for the inspector; it's about creating a workspace that is inherently safer and more efficient. Clear access and organised storage areas are the bedrock of a smooth and effective inspection process.

What Inspectors Look for on Your Racking

When a SEMA-approved inspector walks through your facility, they see your racking system through a highly trained lens. They aren't just looking for obvious, dramatic damage; they're hunting for the subtle signs of stress, wear, and incorrect installation that can compromise the entire structure. Understanding their focus is key to improving your own daily checks and grasping the final report.

An inspector's process is methodical, covering every component from the ground up. They're assessing the overall condition, looking for tell-tale signs of forklift impacts, overloading, and environmental wear. It’s all about building a complete picture of the racking's health.

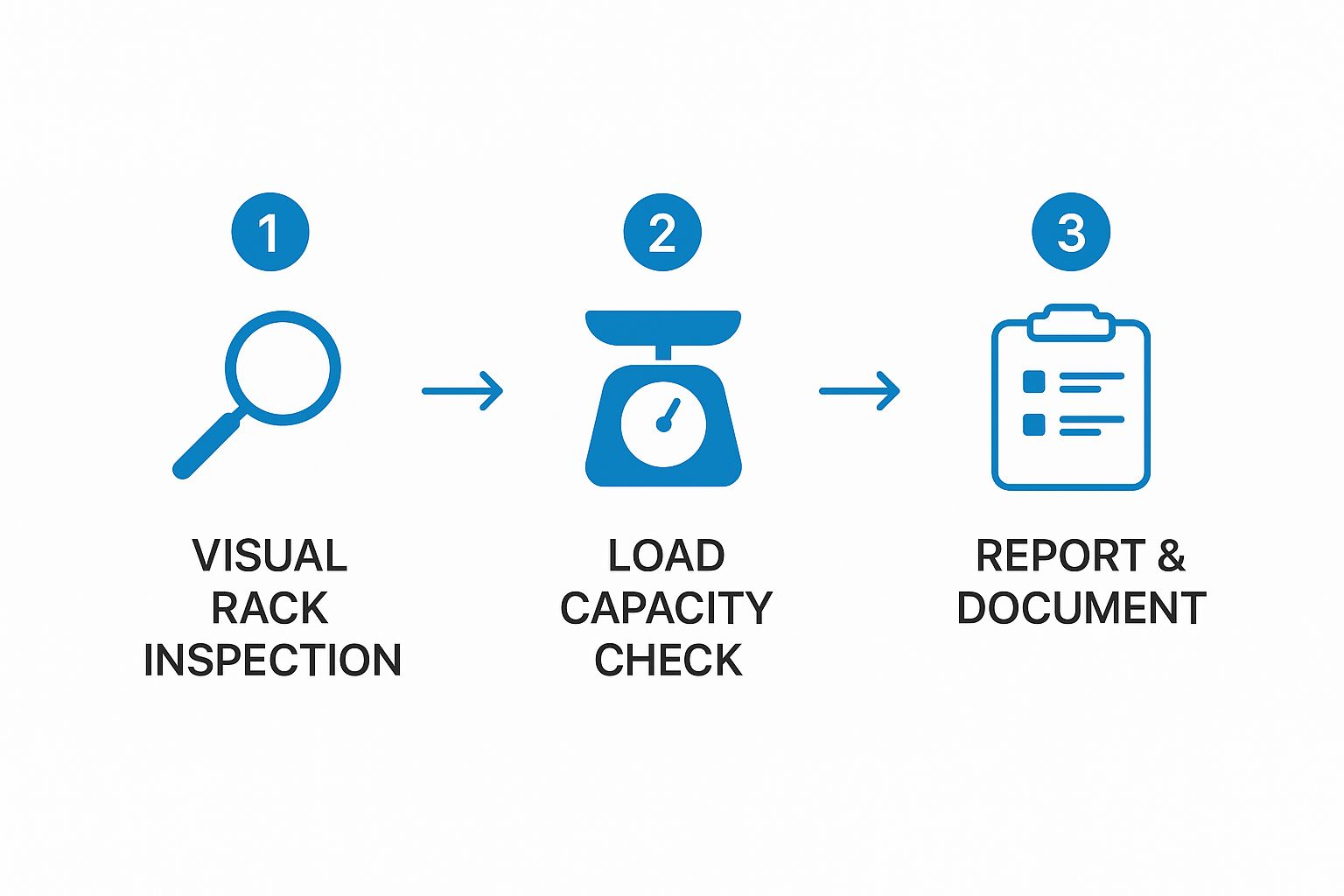

The following infographic illustrates the core stages of a professional racking safety inspection process.

This visual shows the inspection is a structured flow, moving from visual checks to load verification and finally to formal documentation, ensuring a thorough and accountable evaluation.

Core Structural Components Under Scrutiny

Inspectors pay close attention to the fundamental building blocks of your system. They meticulously check for any deviation from the original, safe design.

Key areas include:

- Uprights and Columns: These vertical supports are the most common victims of forklift collisions. An inspector will check for dents, twists, buckling, or scrapes that could weaken the column's load-bearing capacity.

- Bracing: Both horizontal and diagonal braces are examined to ensure they are straight, securely attached, and not twisted. Damaged bracing can lead to frame instability and sway.

- Beams and Connectors: They will look for any signs of deflection or bowing in the horizontal beams, which indicates overloading. Missing or improperly engaged safety clips on beam connectors are also major red flags, as they prevent beams from being accidentally dislodged.

- Floor Fixings and Base Plates: The connection to the floor is critical. Inspectors check that base plates are not damaged and that all anchor bolts are present, secure, and not sheared off.

Properly assessing these components requires expertise, as some damage might look minor but can have serious implications. If you are ever unsure about the integrity of a component, consulting experts who handle both racking manufacture and installation can provide crucial clarity.

Classifying Damage The Traffic Light System

A crucial part of any professional racking safety inspection is classifying the severity of any damage found. This is almost universally done using a simple 'traffic light' system, which provides clear, immediate instructions on what action to take.

This system is designed to remove any guesswork, assigning a colour code to each issue based on its risk level. It tells your team exactly what to do and when.

Racking Damage 'Traffic Light' System Explained

This table breaks down the three levels of damage classification, explaining what each colour means and the response required.

| Damage Level | Colour Code | Description of Damage | Required Action |

|---|---|---|---|

| Needs Surveillance | Green | Minor damage that is currently within SEMA tolerance limits but could worsen over time. | Document the damage, label it as "Green Risk," and schedule a re-assessment at the next inspection. No immediate action is required, but it must be monitored. |

| Requires Prompt Action | Amber | Damage that has exceeded SEMA limits and poses a medium-term risk to safety and structural integrity. | The affected bay must be offloaded as soon as is safely possible. Once empty, it should not be reloaded until repairs are completed. Repairs should be prioritised. |

| Immediate High Risk | Red | Severe damage that presents an immediate and serious risk of collapse or failure. | Immediately offload the affected location and quarantine the area. Do not use the racking under any circumstances until it has been professionally repaired or replaced. This is the highest priority. |

Understanding this system allows you to interpret an inspector’s report effectively and prioritise repairs based on risk. It transforms the inspection from a simple pass/fail exercise into a dynamic tool for ongoing safety management and risk reduction in your operations.

The system categorises damage into three levels, each demanding a different response. Green signifies issues that need monitoring, Amber requires prompt remedial action, and Red demands immediate offloading and quarantine of the affected area.

This classification removes ambiguity. Statistically, this is vital, as accidents in UK warehouses are a significant concern. The Health and Safety Executive (HSE) reports over 1,500 warehouse accidents annually, often linked to equipment faults.

Forklift impacts are a primary cause of racking failure, implicated in around 65% of collapses, while overloading contributes to about 40% of incidents. Discover more insights about these crucial statistics from The Rack Group.

Assessing Hazards Beyond the Racking System

A racking safety inspection that stops at the base plate is only telling half the story. The truth is, your racking's integrity is directly tied to its environment. A complete assessment has to zoom out and look at the operational hazards surrounding the structure, as these factors are often the root cause of failures.

This means looking right down to the foundation. An uneven or cracked concrete floor can make a rack lean or become unstable over time, putting uneven stress on its components. A good inspector will always check the condition of the floor around and under every single base plate.

Evaluating the Operational Space

Beyond the floor, the space where your team and machinery operate is critical. This involves checking that aisle widths are genuinely sufficient for the Materials Handling Equipment (MHE) you’re using, allowing for safe manoeuvring without the constant risk of collision.

Consider these key environmental checks:

- Aisle Widths: Are they compliant with the guidelines for your specific forklifts? Can drivers turn and move safely?

- Lighting Conditions: Is the area bright enough for operators to clearly see the racking, loads, and any potential obstructions? Poor lighting is a well-known contributor to accidents.

- Housekeeping: Are aisles clear of debris, shrink wrap, and stray pallets? These not only create trip hazards but can force MHE operators to take risky routes around them.

Fire is another major hazard, and a comprehensive safety view must include evaluating your facility's protection. Understanding the essentials of warehouse https://psllimited.co.uk/fire-protection is a non-negotiable part of a holistic safety strategy.

A common oversight is assuming that if the racking is undamaged, it must be safe. But a rack on a failing floor or in a poorly lit, cramped aisle is an accident waiting to happen, no matter how good its own condition is.

Protection and Information Systems

Finally, the inspection should verify the protective measures and informational signs that support safe racking use. This means checking that rack protection, like upright guards and end-of-aisle barriers, is present, correctly installed, and in good nick.

Forklift impacts are one of the most common sources of rack damage. A robust forklift pre-start checklist helps ensure MHE is operated safely from the get-go, reducing the primary cause of damage.

Equally important are the Safe Working Load (SWL) signs. An inspector will confirm they are clearly visible, legible, and—most importantly—accurate for the current rack configuration. If beams have been moved or the system has been altered, those original SWL signs may no longer be valid, creating a significant and often hidden risk.

Turning Inspection Reports into Action Plans

The racking safety inspection is done, and the report is on your desk. Don't let it gather dust. This document isn't just a pass-or-fail certificate; it's your roadmap to a safer warehouse. The real work begins now, turning those findings into a concrete, auditable action plan.

Your first job is to actually read the thing—properly. Go beyond a quick scan for the red flags. Pay close attention to the inspector's notes on 'Green' and 'Amber' risks, too. Think of them as early warnings for problems that are just around the corner. A good report will spell everything out: the location, the specific component, and the severity of each issue, usually with photos to leave no room for doubt.

Prioritising Repairs Based on Risk

Once you've got a handle on the issues, it's time to prioritise. The 'traffic light' system makes this part pretty straightforward. Anything marked as a 'Red Risk' is non-negotiable and needs your immediate attention. This isn't something you can schedule for next week. It means the affected racking bays must be offloaded and cordoned off right now, preventing any use until a qualified technician has completed the repairs.

'Amber Risk' items are your next priority. While they don't pose an immediate danger of collapse, they have already exceeded safety limits and need to be fixed promptly. A common mistake is to push these repairs down the to-do list, but that's just letting risk accumulate in your warehouse.

A proactive approach to repairs is a clear indicator of a strong safety culture. It's not just about fixing what's broken; it's about demonstrating to your team, and to regulators like the HSE, that you take your duty of care seriously. This documented diligence can be invaluable in the event of an incident.

The consequences of ignoring these warnings can be severe. Data from the transport and storage sector shows just how high the stakes are. The HSE records around 37,000 workplace injuries each year in this sector alone, with 14 work-related deaths reported in a recent year. You can get more context on these figures from our deep dive into the HSE injury and fatality statistics.

Creating an Auditable Action Log

To keep the repair process organised and accountable, you need to create a formal action log. A simple spreadsheet will do the trick. This creates a clear, auditable trail showing exactly how you've responded to the inspection report.

Your action log should track a few key details for every single issue identified:

- Item Reference: The unique ID from the inspector's report.

- Location: The specific aisle and bay number.

- Risk Level: Red, Amber, or Green.

- Required Action: A clear description of what needs fixing.

- Assigned To: The name of the person or team responsible for getting it done.

- Deadline: A realistic but firm date for completion.

- Completion Date: The actual date the work was finished.

- Sign-Off: Confirmation that the repair has been checked and verified.

Assigning clear ownership is the secret sauce here. When a specific person is responsible for a task, it's far more likely to get done on time. This log becomes a living document that not only guides your maintenance team but also serves as crucial evidence of your compliance and proactive safety management should anyone come asking.

Common Questions About Racking Inspections

When you’re managing a busy warehouse, racking safety can throw up a lot of questions. From your legal duties to the nuts and bolts of handling damage, clear answers are vital for running things smoothly and, most importantly, keeping your people safe.

We’ve pulled together some of the most common queries we hear from warehouse managers. Think of this as your go-to guide for demystifying the whole process.

How Often Should Racking Be Inspected in the UK?

This is easily the question we get asked the most, and the answer isn’t just a simple number. The law is crystal clear: the Provision and Use of Work Equipment Regulations 1998 (PUWER) requires a formal inspection from a "technically competent person" at least once every 12 months.

But that’s just the legal minimum—the absolute baseline. In the real world, especially in high-activity warehouses, you’ll need to do more.

- High-Traffic Warehouses: If your aisles are buzzing with forklifts and stock is constantly moving, getting an expert in every six months is a smart move. More activity simply means a higher risk of bumps and knocks.

- Internal Checks: That big annual inspection should be backed up by regular checks from your own team. A trained staff member, often called a Person Responsible for Racking Safety (PRRS), should be doing visual walkthroughs weekly, or even daily, to spot fresh damage as soon as it happens.

The "once a year" rule is your starting point, not the finish line. How often you inspect should be a direct reflection of your operational risk.

Internal vs. External Inspections: What's the Difference?

It’s really important to get your head around the difference here, because these two types of inspections do different jobs. They work together, but you can’t swap one for the other.

An internal inspection is your frontline defence. It's a regular, more informal check done by one of your own trained employees. They’re looking for the obvious stuff—a dented upright, a twisted brace, a missing beam clip—and flagging it immediately so it can be properly assessed. It’s all about constant watchfulness.

An external inspection, on the other hand, is the official, deep-dive assessment carried out annually by an independent, certified expert, like a SEMA Approved Racking Inspector (SARI). This is the inspection that keeps you legally compliant. These pros bring an unbiased eye and have the training to spot subtle issues an untrained person would easily miss, protecting the long-term structural integrity of your system.

What Should We Do if a Red Risk Is Found?

Finding a 'Red Risk' during an inspection is a stop-everything moment. It’s the most critical warning you can get, signalling severe damage that poses an immediate threat of collapse. There’s no room for hesitation.

The procedure is non-negotiable and must be followed to the letter:

- Offload Immediately: The affected racking bay needs to be carefully and completely emptied of all stock.

- Quarantine the Area: Cordon off the entire bay to stop anyone from accessing it. Use clear, unmissable signs warning staff that the racking is unsafe and out of bounds.

- Do Not Reload: Under any circumstances, the racking must not be used again until a qualified technician has replaced the damaged parts and has officially signed off the repair as safe.

Trying to patch it up or continuing to use red-risk racking is a massive breach of safety rules and puts your entire operation, and your team, in serious danger.

At Partitioning Services Limited, we design and install robust storage solutions that are built to last. If your latest inspection has flagged a need for expert repairs or a full system upgrade, contact our team today. We’ll help you get your warehouse safe, compliant, and running at peak efficiency.

Looking for help with your next project?

Whether you are new to self storage or already have an established self storage facility, we can provide you with guidance and a full quotation for any aspect of your works.