Running out of space is one of the biggest growing pains a business can face. Before you start looking at the massive cost and disruption of moving or building an extension, there’s another option: look up. An industrial mezzanine floor is a clever way to create a brand-new, usable level inside your existing building. It essentially doubles your footprint without the headache of a major construction project.

Unlocking Your Vertical Potential with Mezzanine Floors

Think of a mezzanine floor as adding a fully functional second storey to your facility, but one that’s installed faster, more flexibly, and at a fraction of the cost. It’s a smart solution to a common problem: your ground floor is getting crowded, but you have metres of unused air overhead. Instead of expanding outwards, you build upwards—a strategy that’s as cost-effective as it is operationally efficient.

This guide is about showing you how this structure is more than just an extra level. It's a strategic asset for unlocking the hidden potential in your building, transforming your operational capacity and, ultimately, your bottom line.

Transforming Wasted Air into Valuable Assets

An industrial mezzanine floor isn't just a big shelf; it's an engineered, integrated extension of your workspace. These platforms are custom-designed to handle your specific operational needs, turning all that empty vertical space into highly productive areas. The benefits are immediate:

- Increased Usable Space: Instantly gain more square footage for storage, offices, production lines, or even observation decks without touching the building’s exterior.

- Cost-Effective Expansion: You get to sidestep the huge expenses that come with moving, new construction, or leasing another property. The return on your investment comes much faster.

- Minimal Disruption: Installation is worlds away from traditional construction. It’s significantly quicker, meaning your day-to-day operations can carry on with little to no interruption.

- Enhanced Operational Workflow: By creating dedicated zones for different activities—storage upstairs, production downstairs—you can streamline processes, clear up clutter on the main floor, and improve overall efficiency.

By converting unused vertical space into functional floor area, an industrial mezzanine floor can increase a facility's usable footprint by as much as 100%. This directly impacts productivity and profitability without the need for physical expansion.

The applications are incredibly diverse and can be tailored to solve unique business challenges. While many people think of them purely for storage, a well-designed mezzanine can easily house complex machinery, client-facing showrooms, or essential administrative hubs. To get a better idea of how these versatile platforms adapt, you can explore the applications of commercial mezzanine floors and see how they solve specific spatial challenges.

This guide will walk you through everything from the core design principles to the necessary safety regulations, giving you a practical look at this powerful solution.

What Exactly Is an Industrial Mezzanine Floor?

Let’s get straight to the point. Forget the dry, technical definitions for a moment.

Imagine the high-ceilinged space in your warehouse, factory, or self-storage unit. All that empty air above your head? That's untapped potential. An industrial mezzanine floor is essentially a freestanding, semi-permanent second level built within that existing space, creating a whole new floor from nothing but air.

This isn’t part of your building’s original bones. Instead, think of it as a cleverly engineered steel platform designed to add a serious amount of usable square meterage. It’s a powerful tool for expanding upwards, letting you unlock valuable overhead space without the headache and eye-watering expense of traditional construction.

This ability to add space quickly and efficiently is catching on. In the UK, the mezzanine floor market is growing steadily, projected to climb from £4.2 billion in 2025 to £7.8 billion by 2033. That’s a compound annual growth rate (CAGR) of about 5.7%, largely fuelled by the booming warehouse and self-storage sectors. For a deeper dive into market trends, check out the full report on the future of mezzanine floors on futuremarketinsights.com.

The Anatomy of a Mezzanine Structure

At first glance, an industrial mezzanine might look complex, but it’s really just a few key parts working in harmony to create a safe, solid platform. Think of it like a skeleton supporting a body.

- Main Beams (Primary Beams): These are the big players—the backbone of the whole structure. They’re the largest steel beams spanning between the support columns, shouldering the bulk of the floor’s weight.

- Joists (Secondary Beams): Running at a right angle to the main beams, these smaller beams form a dense grid. Their job is to spread the load evenly across the structure and lock everything together for stability.

- Support Columns: These are the legs of the mezzanine. These vertical steel posts transfer the entire load from the beams and joists safely down to your building’s concrete floor slab.

- Decking: This is the floor you walk and work on. It’s laid over the grid of joists and can be made from anything from 38mm heavy-duty particle board to steel chequer plate, depending on what you’re using it for.

Together, these components create a system that can be precisely engineered to handle just about anything—from light-duty office equipment to heavy industrial machinery.

Core Types of Industrial Mezzanine Floors

Not all mezzanines are created equal. The right design really depends on what you need it to do. Getting to grips with the main types is the first step in figuring out which solution is the right fit for your goals.

A huge plus for modern mezzanines is their semi-permanent nature. Unlike a permanent structural addition, they can often be dismantled, moved, or reconfigured. This gives you incredible long-term flexibility as your business needs change.

The most common designs you’ll come across are freestanding, rack-supported, and steel-integrated systems. Each one is built for a different purpose, whether it’s simply adding more storage or creating a complex, multi-level hub for your operations.

To make it clearer, here’s a simple breakdown of the most common types you’ll find in an industrial setting.

Comparing Common Industrial Mezzanine Floor Types

This table compares the primary types of industrial mezzanine floors, helping you understand the best application, typical load capacity, and key advantages of each to make an informed decision.

| Mezzanine Type | Best Use Case | Typical Load Capacity (kg/m²) | Key Advantage |

|---|---|---|---|

| Freestanding | Ideal for creating office space, work platforms, or general storage areas above an open ground floor. | 350 – 750 | Maximum Flexibility: It doesn't rely on existing structures, allowing for versatile placement. |

| Rack-Supported | Best for high-density storage where the shelving or racking system itself forms the structure. | 250 – 500 | Space Efficiency: Combines storage and a raised floor into one highly efficient system. |

| Integrated Steel | Used in complex production or sorting facilities where the mezzanine is part of a larger machinery system. | 750 – 1500+ | High Strength: Custom-engineered to support heavy machinery and dynamic loads. |

Choosing the right type depends entirely on your operational needs. A freestanding mezzanine offers unbeatable flexibility for general use, while a rack-supported system is perfect for maximising every inch of storage space. For heavy-duty industrial applications, an integrated steel structure provides the muscle you need.

Key Design and Structural Considerations

A successful mezzanine floor isn’t just about adding square footage; it's a precisely engineered structure that must be safe, functional, and perfectly suited to its purpose. Getting the design and structural details right from the very beginning is the difference between a high-performing asset and a costly mistake.

Think of it like laying the foundation for a house. You wouldn't just start building without a detailed blueprint, and the same principle applies here. Every decision, from the load capacity to the column placement, has a direct impact on the safety of your team and the efficiency of your operations. This is where the real value is forged, ensuring your mezzanine can handle today's demands and adapt to tomorrow's.

Determining the Right Load Capacity

The most fundamental question in any mezzanine design is simple: "What are you putting on it?" The answer to this dictates the entire structural engineering of the platform. Load capacity, measured in kilonewtons per square metre (kN/m²), defines how much weight the floor can safely support.

A structure intended for a few desks and light foot traffic will have vastly different requirements from one designed to hold heavy machinery or dense pallet racking. Getting this wrong is not an option. Under-engineering is a serious safety risk, while over-engineering is just a waste of money.

To make sure we get it right, load capacity is broken down into clear categories:

- Light-Duty Storage (approx. 3.5 kN/m²): Perfect for hand-loaded shelving, archive boxes, or areas with minimal foot traffic.

- General Storage (approx. 4.8 kN/m²): This is the workhorse. It’s the most common specification, built for standard palletised goods moved with pallet trucks.

- Heavy-Duty Production (approx. 9.6 kN/m² or higher): Engineered to support heavy equipment, busy production lines, or high-density storage systems.

A professional assessment won't just look at the static weight (the dead load) of stored items. It also has to account for the dynamic forces (the live load) from moving people, pallet trucks, or machinery.

Strategic Column Layout and Grid Design

The columns are the legs of your mezzanine, transferring the entire weight of the structure—and everything on it—down to the concrete slab below. Their placement is a strategic balancing act, aimed at maximising stability while causing minimal disruption to your ground-floor operations.

Ideally, you want the column grid spaced as widely as possible to keep the area underneath open and clear for forklift traffic, machinery, or workstations. But wider spans require bigger, heavier, and more expensive primary beams to carry the load. The real skill is finding that sweet spot between open space and cost-effectiveness.

The condition of your existing concrete floor is also a massive factor. It has to be strong enough to handle the concentrated point loads from each column without cracking or failing.

The design process almost always involves a ground survey to test the concrete slab's integrity. This confirms that the proposed column loads won't cause issues down the line, guaranteeing the long-term stability and safety of the whole installation.

Of course, beyond the initial design, you need to think about the future. Ongoing structural integrity is paramount, making it essential to plan for maintenance and have access to comprehensive industrial repair solutions for the long haul.

Choosing the Right Decking Material

The decking is the surface you'll walk and work on every day, and your choice of material directly impacts its durability, safety, and function. What you need depends entirely on how you plan to use the space.

A simple storage area might only need basic particle board, but a workspace with heavy machinery demands something far more robust.

- 38mm Particle Board: This is the standard, most cost-effective option. It's ideal for general storage, office space, and light production areas.

- Composite Decking: This features a steel base with a particle board overlay, giving you extra strength and a much quieter, more solid feel underfoot. It’s a great choice for areas with high pallet truck traffic.

- Steel Chequer Plate: Extremely durable and hard-wearing. This is the go-to for tough industrial environments, especially where welding, sparks, or chemical spills are a concern.

- Open Mesh or Grate Decking: This allows light and air to pass through, which is great for visibility and can be a requirement for fire suppression systems. You'll often see it used in multi-tier structures.

Each material offers a different balance of cost, durability, and performance. Making the right choice here is a key step in tailoring the mezzanine perfectly to your operations.

Navigating UK Building Regulations and Safety

Putting in an industrial mezzanine floor is more involved than just setting up a new platform. To make sure your structure is safe, legal, and truly fit for purpose, you have to work within a specific set of UK Building Regulations. It’s best to think of these rules not as bureaucratic hurdles, but as a blueprint for safety—one that protects your team, your assets, and your business from serious risks.

Compliance isn’t optional. Failing to meet these standards can lead to hefty fines, orders to shut down operations, or in the worst-case scenario, a catastrophic structural failure. That’s why getting a handle on the core principles of the regulations is an essential first step, long before the design process even kicks off. It's all about building a fundamentally safer and more efficient work environment from the ground up.

Workplace safety statistics paint a very clear picture of why this is so important. In 2018-19, the Health and Safety Executive (HSE) recorded nearly 44,000 workplace injuries linked to missing or faulty safety features like guardrails and gates. This has prompted a 25% increase in regulatory inspections since 2020, putting a much bigger spotlight on industrial safety.

Core UK Regulations You Must Know

While the full scope of building regulations is massive, a few key parts are directly relevant to any industrial mezzanine project. These standards work together to ensure the structure is not just strong but also safe for people to use day in and day out. Grasping these essentials is the first step toward a compliant, problem-free installation.

- Part B (Fire Safety): This is arguably the most critical one. If your mezzanine is particularly large or used for more than just storage (like housing offices), it may need to be fire-rated for up to 60 minutes. This usually means protecting the steel structure with things like suspended ceilings, column casings, and fire-resistant fascias to slow the spread of a fire and give everyone time to evacuate safely.

- Part K (Protection from Falling, Collision and Impact): This regulation is all about the safety of stairs, ramps, and guards. It sets out the minimum height for handrails and edge protection (guardrails), the proper design of staircases to prevent trips, and the need for features like pallet safety gates to protect workers at exposed edges.

- Part M (Access to and Use of Buildings): This one ensures the mezzanine is accessible. While full disabled access isn't always mandatory for a purely industrial storage platform, Part M becomes crucial if the mezzanine has offices or other workspaces. It influences the design of staircases and access points to make them usable for everyone.

It's crucial to remember that almost every industrial mezzanine floor requires Building Regulations approval. This is completely different from Planning Permission, which is rarely needed unless the mezzanine significantly changes the building's external appearance or its intended use.

Getting your head around these requirements can feel complex, but it’s a non-negotiable part of any project. For a deeper dive into the whole process, you can find a lot of valuable information in our guide on how building regulations apply to mezzanines.

Practical Safety Features in Action

Meeting regulations isn’t just about ticking boxes on a form; it's about putting tangible safety features in place that protect your team every single day. These components are specifically designed to handle the most common risks that come with working at height.

One of the most vital elements is edge protection. Any exposed edge of the mezzanine must have a robust guardrail system, often called a balustrade. This barrier is your first and most important line of defence against falls. For the nitty-gritty on making sure your mezzanine's safety barriers are up to legal standards, it's worth consulting a practical guide to balustrade regulations.

On top of that, other key features include:

- Staircases: These need to be designed with the right tread depth, riser height, and width to make sure passage is safe and easy. They also must have continuous handrails on at least one side.

- Pallet Gates: If you're loading and unloading goods with a forklift, these are an absolute must. A "swing" or "up-and-over" gate design ensures that the edge of the mezzanine is never left exposed, protecting workers from a dangerous fall.

- Lighting and Signage: It sounds simple, but proper lighting is a requirement to prevent trips and falls. You’ll also need clear signage that indicates load limits, headroom, and exit routes to maintain a safe working environment.

By integrating these safety measures right from the initial design phase, you’re not just maximising space—you’re creating a secure, compliant, and long-lasting asset for your business.

Right, so you know the theory and the design principles. But what does a mezzanine floor actually do for a business? That's where the real value becomes clear—when you see these structures solving genuine, everyday problems.

Mezzanines aren't just an abstract concept from an engineering textbook. Think of them as practical, powerful tools that businesses in all sorts of industries are using to beat space constraints, sharpen their efficiency, and ultimately, grow their bottom line.

By looking at how others are using them, you can start to see how a mezzanine could tackle the specific challenges in your own facility. Each example is a story of a business that decided to build up instead of out, completely transforming their operations from the inside.

E-commerce and Fulfilment Centres

The explosion of e-commerce has put incredible pressure on warehouses and fulfilment centres. Order volumes are all over the place, product ranges are constantly expanding, and the demand for faster picking and packing never stops. In this kind of environment, an industrial mezzanine floor is an absolute game-changer.

Picture a single-level warehouse. The aisles are clogged, and order picking is painfully slow. Now, imagine installing a multi-tier mezzanine. Suddenly, you can create dedicated zones for different tasks.

- Ground Floor: This area can be kept clear for receiving goods, storing bulky items, and dispatching orders. All the heavy forklift traffic stays contained right where it needs to be.

- Mezzanine Level: The new upper floor becomes a streamlined order-picking zone lined with organised shelving. Staff travel time is slashed, and fulfilment gets a whole lot quicker.

This simple separation of tasks makes the entire workflow run smoother. One company we know of reported a 30% jump in their order processing speed after adding a two-tier picking system on a mezzanine. That’s a direct impact on their ability to keep customers happy.

Manufacturing and Production Facilities

In manufacturing, every square metre of floor space is prime real estate. Trying to squeeze in a new production line or an oversight office can feel impossible without shelling out for a costly building extension. A mezzanine offers a much smarter, more efficient way forward.

Take a factory that needs to add a quality control station but can't afford to disrupt the main assembly line. A freestanding industrial mezzanine floor can be built right over the production area. This not only creates a dedicated space for technicians but also gives them a perfect bird's-eye view of the entire operation.

The real win here is being able to house all those extra functions without eating into your valuable ground-floor production space. This could be anything from a manager’s office with big windows overlooking the floor to a clean room for sensitive assembly work.

Self-Storage and Warehousing

The self-storage and warehousing industries are in a constant battle for space, particularly in crowded urban areas. Mezzanine floors have become indispensable here, letting facilities literally multiply their rentable square footage without changing their building's footprint.

Mezzanine floors have become a vital tool in the UK's self-storage and warehousing sectors. In fact, industrial facilities are the biggest users, making up around 45% of the market. This is all driven by the need for cost-effective vertical expansion, especially with land being so scarce in high-demand spots like the Midlands and the Southeast. You can read more about trends in the mezzanine floor market from globalinsightservices.com.

A simple single-storey unit can be completely transformed into a multi-level facility, with each new tier filled with rows of secure storage units. It’s a straightforward strategy that directly increases the number of customers a single site can handle, maximising revenue from every square metre.

Retail and Back-of-House Operations

For any retail business, a chaotic stockroom is a recipe for disaster. It leads to disorganised inventory, which means slow restocking on the shop floor. A retail mezzanine installed in the back-of-house area is the perfect, immediate fix.

It creates an organised, two-level system. Seasonal items can be tucked away on the upper level, while the fast-moving stock stays right below, ready to go. This simple change helps staff find products in a fraction of the time, ensuring the shop floor is always well-stocked and looking its best—which is a direct win for the customer experience.

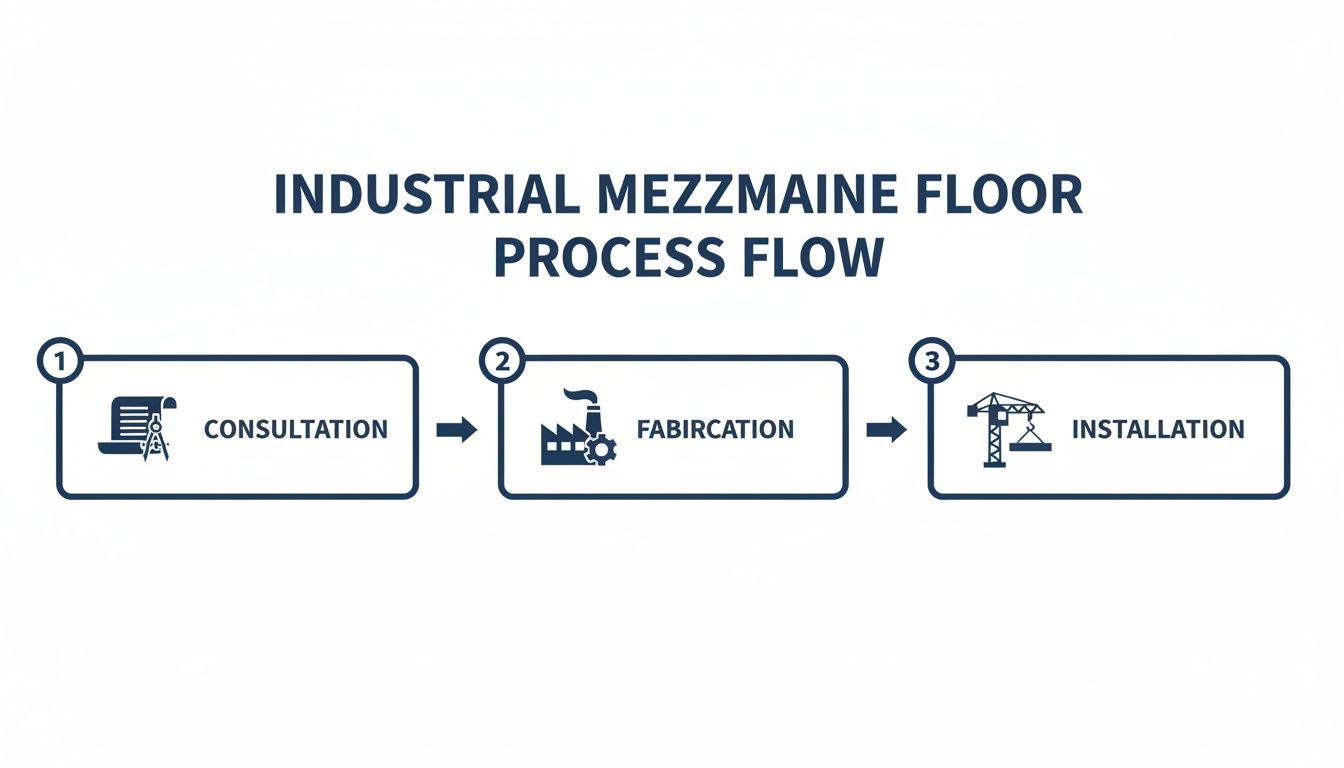

The Installation Process from Concept to Completion

Bringing an industrial mezzanine floor to life is a structured, multi-stage project, but it’s far quicker and less disruptive than you might think. Understanding the journey from an initial idea to a fully functioning platform helps demystify the process. It shows how a complex structure is managed with precision to keep your business running smoothly.

The whole project is a partnership, starting the moment you decide to explore your vertical space. It’s a transparent workflow designed to deliver a safe, compliant, and highly functional asset that’s built around your exact operational needs.

Stage 1: Initial Consultation and Site Survey

Everything starts with a detailed conversation. A specialist will visit your site to get a feel for your goals—whether that’s creating new storage, adding office space, or building a production platform. This is a fact-finding mission to measure the available space, assess the condition of your concrete floor slab, and spot any potential obstructions like existing machinery or services.

During this phase, we'll talk through your desired load capacity, intended use, and access requirements. This initial survey ensures the final design is not only practical but also structurally sound and perfectly slotted into your existing workflow.

Stage 2: Design Engineering and Quotation

With the site data gathered, the design team gets to work. Using specialised software, they create a detailed 3D model of your proposed mezzanine floor. This blueprint maps out every single component, from the exact column grid and beam placement to the staircase locations and decking type.

This design phase is where regulatory compliance is engineered into the structure from the ground up, making sure it meets all relevant UK Building Regulations for fire safety and fall protection. Once the design is finalised, you receive a comprehensive quotation detailing all costs.

This visual shows how each distinct phase—consultation, fabrication, and installation—flows logically into the next, ensuring a controlled and efficient project timeline.

Stage 3: Fabrication and On-Site Installation

Once you approve the design, all steel components are precision-engineered and fabricated off-site in a controlled factory environment. This approach guarantees high-quality manufacturing and dramatically cuts down on-site construction time and disruption. While the components are being made, the installation team prepares your site.

The prefabricated parts are then delivered to your facility, ready for assembly. A skilled team erects the structure quickly and safely, often working around your operational schedule to minimise downtime. The process includes installing columns, beams, decking, and safety features like handrails and staircases.

For a look at different access options, our guide on rolling staircases offers insight into smooth and versatile solutions that can be integrated into your design. Finally, after a thorough quality inspection, the new level is handed over, ready for you to use.

Your Questions About Industrial Mezzanines, Answered

Thinking about adding a mezzanine floor is a big step. It’s a serious investment in your operational space, so it's only natural to have a few questions before you commit. We get it.

To help you get your head around the process, we've pulled together the most common queries we hear from clients. This isn't jargon-heavy technical speak; it's straight-up, practical advice covering everything from timelines and regulations to costs and long-term flexibility. Our goal is to give you the confidence to make the right call for your business.

How Long Does a Typical Mezzanine Installation Take?

It’s much faster than you might think, and certainly quicker than traditional construction. A standard mezzanine project, from the first site survey to the final handover, usually takes between four to eight weeks.

Of course, a few things can influence that timeline:

- Size and Complexity: A simple, small storage platform is always going to be quicker to install than a huge, multi-tier structure with integrated offices and bespoke staircases.

- Site Conditions: An empty, open warehouse is the ideal scenario. If our teams need to work around active machinery and your staff, it naturally adds a bit of time to the job.

- Regulatory Approval: We also need to factor in the time it takes to get the green light from Building Regulations.

Do I Need Planning Permission for a Mezzanine?

This is probably the most common question we get, and it causes a lot of confusion. The simple answer is almost always no.

Because an industrial mezzanine is a freestanding, semi-permanent structure built inside your existing building, it doesn’t change the external appearance of the property. For that reason, it typically falls outside the scope of Planning Permission.

What you absolutely will need is Building Regulations approval. This is a completely separate process that has nothing to do with planning consent. It's all about safety—making sure the structure is strong, fire-rated correctly, and has safe access. Don't worry, we handle this for you.

What Factors Determine the Cost of a Mezzanine Floor?

The final price tag is tailored specifically to your project, but a few key variables drive the cost. The main one is obviously the size in square metres, but it's not the only factor.

The required load-bearing capacity is a huge one—a floor for light storage will cost less than one designed to support heavy machinery. The type of decking you choose (e.g., standard particle board vs. durable steel chequer plate) and the overall complexity of the design also play a big part.

Finally, we'll factor in things like staircases, pallet safety gates, and any fire protection measures required by the regulations.

Can a Mezzanine Floor Be Moved or Relocated?

Yes, and this is one of the biggest advantages of a steel mezzanine. These structures are cleverly designed to be semi-permanent. They are bolted together on-site, not welded, which means they can be dismantled, moved to a new building, or even just reconfigured in the same place if your needs change down the line.

This flexibility turns your mezzanine into a true long-term asset. Unlike a permanent concrete floor, your investment isn't locked to one physical location. It can adapt and move right along with your business, which is fantastic value.

This adaptability means your initial investment is protected for years to come, giving you a solution that can evolve as your business does.

Ready to unlock the hidden potential in your facility? The team at Partitioning Services Limited has spent over two decades designing and installing bespoke industrial mezzanine floor solutions. Visit us at https://psllimited.co.uk to schedule a free site survey and see how we can double your usable space.

Looking for help with your next project?

Whether you are new to self storage or already have an established self storage facility, we can provide you with guidance and a full quotation for any aspect of your works.