Imagine doubling your usable floor space without the eye-watering cost and disruption of moving premises or building an extension. That’s the strategic ace up the sleeve that mezzanine floors offer UK businesses, especially in warehousing, self-storage, and retail, where every square metre counts. This guide will show you how to turn that unused vertical space into a powerful operational tool.

Unlock Your Building’s Hidden Potential

A mezzanine floor isn't just a platform; it's a seriously cost-effective way to expand upwards. Think of it as an intermediate level built between the main floors of your building, basically creating new, usable space out of thin air. For any business feeling squeezed by its current footprint, this is a direct path to growth without the headache of relocation.

Across the UK, the demand for these structures is climbing, and it's no surprise. It’s being driven by two massive factors: soaring commercial property costs and the relentless boom of e-commerce. As businesses wrestle with ever-increasing stock levels and operational demands, the need for smart space utilisation has never been more critical. A well-designed mezzanine tackles this challenge head-on.

Why Consider a Mezzanine Floor?

Installing a mezzanine floor brings real, tangible benefits that go way beyond just adding square footage. It’s all about making your existing space work smarter for you. The key advantages are pretty compelling:

- Cost Efficiency: It is significantly cheaper than building an extension or moving to a bigger facility. No contest.

- Operational Improvement: That extra space can become storage, new office areas, or production lines, easing the operational bottlenecks happening on the ground floor.

- Flexibility: Mezzanines are often demountable. That means they can be reconfigured, moved, or removed entirely as your business needs change down the line.

A mezzanine floor transforms dormant overhead space into a dynamic asset. It’s the ultimate space-saving solution for any business feeling the pressure of its physical limits, turning a potential liability into a genuine opportunity for expansion and efficiency.

In a way, mezzanine floors unlock your building's hidden potential, much like an extension and loft conversion does for a home. The principle is exactly the same: getting the absolute most out of the structure you already have to support your growth.

A Practical Guide for Decision-Makers

This guide is for the facility managers, property developers, and business owners who need a clear, no-nonsense path forward. We're going to move past the basic concept and dive deep into the practical stuff that ensures a project is a success. We’ll cover everything from navigating UK building regulations and making smart design choices to estimating costs and choosing a reliable installer.

By understanding the full scope of a mezzanine project, you can make an informed decision that delivers a strong return on your investment. The goal here is to arm you with the knowledge to commission a structure that doesn't just add space, but actively enhances your business's productivity and value.

Navigating UK Building Regulations and Approvals

Putting in a mezzanine floor isn't just a construction job; it's a project that has to meet strict UK safety standards designed to protect people and property. Getting your head around this regulatory landscape isn't a box-ticking exercise—it’s absolutely essential for a safe, legal, and successful installation. Get it wrong, and you could be facing hefty fines, orders to do costly remedial work, or even being told to tear the whole thing down.

The main set of rules you need to follow are the UK Building Regulations. This is completely different from planning permission. While planning permission deals with a building's external look and its use, Building Regulations are all about the technical side of health and safety. For mezzanine floors, they are non-negotiable.

Building Regulations vs Planning Permission

This is a common point of confusion, but the difference is critical. The good news is that most mezzanine floors installed inside an existing building do not require planning permission. Because they're seen as internal, demountable structures, they don't usually change the outside appearance or the footprint of your property.

However, Building Regulations approval is almost always mandatory. This approval is what ensures your new structure is legally compliant and safe. A good way to think about it is that planning permission asks if you can build something, whereas Building Regulations dictate how you must build it to be safe.

A simple rule of thumb: If your mezzanine affects the structural safety, fire escape routes, or accessibility of your building, it requires Building Regulations approval. This covers nearly every commercial installation in the UK.

Key Regulatory Parts You Must Address

To get approval, you’ll need to satisfy several key sections of the Building Regulations, often called 'Approved Documents'. For any mezzanine project, three parts are especially important:

Part A (Structure): This is all about making sure the mezzanine floor is structurally sound. It must be able to hold its own weight, plus the weight of everything you plan to put on it (stock, machinery, staff), and be properly connected to the main building's foundations. You'll need calculations from a qualified structural engineer to prove it's up to the job.

Part B (Fire Safety): This is one of the most critical hurdles. Adding a new floor level completely changes how a fire might spread and how people can get out safely. This part of the regulations covers everything from fire detection and escape routes to travel distances. Crucially, it often requires the mezzanine’s structure to be fire-protected to provide a minimum of 60 minutes of fire resistance.

Part M (Access and Use): This document ensures the new mezzanine is accessible to everyone, including people with disabilities. Depending on what you're using the mezzanine for (like office space for staff), this might mean you need to include features like an accessible staircase or even a platform lift.

An essential step in any building project is ensuring full compliance with UK building regulations, and a dedicated Building Regulations Checker can help streamline this process.

The Approval Process Explained

To get the green light, you or your supplier will need to submit a detailed application to either your Local Authority Building Control (LABC) or a private Approved Inspector. This application pack has to include architectural drawings and all the structural calculations that prove you've met every requirement.

The demand for these structures shows just how valuable they've become. The UK mezzanine floor market is booming, valued at an estimated USD 4.2 billion in 2025 and projected to surge to USD 7.8 billion by 2033. This growth is built on a foundation of strict compliance, with UK building codes under the Building Regulations 2010 ensuring fire protection and load-bearing capacities up to 500kg/m².

This is why working with a specialist supplier who knows this process inside and out is so important. They can manage the entire application for you, making sure every technical detail is spot on and dealing with the inspectors. You can learn more about the specifics by exploring our detailed guide on understanding mezzanine building regulations. Getting this right from the very beginning saves you from costly delays and makes sure your investment is safe, secure, and fully legal for years to come.

Designing a Mezzanine for Maximum ROI

A successful mezzanine is far more than just a simple platform; it’s a carefully engineered asset designed to boost your return on investment. The design phase is where you make the critical decisions that directly impact your bottom line, transforming a steel structure into a powerful tool for operational efficiency.

Smart design choices ensure every square metre of your new level works hard for your business, turning dead air into a productive, profitable space.

This whole process kicks off by nailing down its intended purpose, which then dictates everything from structural strength to the flow of people and goods. A mezzanine intended for light office use has completely different requirements from one supporting heavy machinery or dense pallet racking. Getting this right from the start prevents costly over-engineering or, even worse, a structure that can't safely handle its workload.

Calculating Your Load Capacity

The single most important design factor is load-bearing capacity, measured in kilonewtons per square metre (kN/m²). This figure represents the maximum weight the floor can safely support, and it’s non-negotiable. It’s crucial to calculate this based not just on what you need today but on future projections to ensure your investment remains valuable for years to come.

Getting this calculation right is a fundamental part of complying with UK Building Regulations. An experienced supplier will work closely with you to define your operational needs and specify a load capacity that is both safe and cost-effective.

To give you a clearer picture, here’s a quick breakdown of what different commercial spaces typically require.

Mezzanine Floor Load Capacity Guide

| Intended Use | Typical Load Requirement (kN/m²) | Common Applications |

|---|---|---|

| Light-Duty Storage | ~3.5 kN/m² | Archiving, storing small parts, or creating walkways. |

| Office Space | ~5.0 kN/m² | Supporting staff, furniture, and standard office equipment. |

| Heavy-Duty Storage | ~7.5 kN/m² | Storing palletised goods, using pump trucks, or medium-weight machinery. |

| Production & Machinery | 10.0+ kN/m² | Housing heavy industrial equipment, high-density storage, or automated systems. |

As you can see, the difference between a floor for office desks and one for production machinery is significant. This is why a thorough assessment at the start is so important.

Choosing the Right Structural System

Once you know the required strength, the next step is choosing the structural system that best fits your space and application. The two main types of mezzanine floors UK businesses use are freestanding and rack-supported. Each offers distinct advantages depending on your goals.

A freestanding mezzanine is a self-supporting structure built on its own columns. It offers maximum flexibility as it doesn't rely on the building's existing framework or any racking below. This makes it ideal for creating open-plan office space, production areas, or retail floors where an unobstructed ground floor is essential.

In contrast, a rack-supported mezzanine integrates the floor directly into a pallet racking system. The racking uprights themselves form the support columns for the mezzanine deck above. This is an incredibly efficient solution for warehouses, as it doubles your storage capacity within the same footprint—you get racking below and a usable floor on top. To see how this concept can be applied, check out our guide on innovative mezzanine floor designs to optimise your self-storage space.

The choice between freestanding and rack-supported isn't just technical—it's strategic. A freestanding design prioritises ground-floor flexibility, while a rack-supported system maximises storage density.

Optimising Layout for Workflow

Finally, intelligent design focuses on how the mezzanine will be used day-to-day. This means thinking carefully about the placement of columns, staircases, and access points to ensure a smooth and efficient workflow.

Optimal column placement is key to minimising disruption on the ground floor. A good designer will create a column grid that works around your existing layout, keeping machinery paths, doorways, and key operational zones clear.

Similarly, staircase positioning is vital. Staircases should be located to provide the most direct and logical access routes for staff, preventing unnecessary travel time and boosting productivity. By integrating these design elements thoughtfully, your mezzanine becomes more than just extra space—it becomes a catalyst for a more efficient and profitable operation.

Understanding the True Cost of Your Mezzanine Floor

Getting the budget right is the foundation of any successful commercial project, and a mezzanine floor is no exception. While it’s tempting to hunt for a simple price-per-square-metre, the reality is that the final cost is shaped by a whole host of project-specific details. Understanding these factors is the key to creating a realistic budget and sidestepping any nasty financial surprises down the line.

Think of the headline figure as just your starting point. The true cost is a mix of the core structure itself, all the essential safety features, and the necessary professional services that go with it. Every decision you make, from the type of decking to the complexity of the design, will have a direct knock-on effect on the final invoice.

Breaking Down the Core Costs

The main things driving your mezzanine's price tag are the materials and the design specs. If you need it to hold a heavier load, you'll need more substantial steel beams and columns, which naturally pushes up the material cost. In the same way, a complex layout with funny shapes or multiple staircases is always going to be more expensive than a straightforward rectangular platform.

Let's get into the primary cost factors:

- Size and Load Capacity: This is the big one. A larger floor or one engineered to support heavy machinery will demand more steel, bumping up the price.

- Decking Material: Your standard 38mm particle board is the most common and wallet-friendly choice. But if you need something more specialised, like composite decking, steel chequer plate, or moisture-resistant boards, you’ll need to factor that into the budget.

- Design Complexity: The column grid plays a huge role here. A design with fewer columns and longer spans between them needs heavier, pricier steel beams to do the job.

- Staircases and Access: The number and type of staircases you need are a significant cost. The same goes for any pallet gates or goods lifts required to move stock up and down.

Uncovering the Hidden Costs

Beyond the steel and timber, there are several other critical costs that you absolutely have to factor in. These are the things that often get missed in initial estimates but are completely non-negotiable for a safe and compliant installation.

The total investment in a mezzanine floor isn't just the price of the structure. It includes the vital services and safety measures that ensure it’s legal, safe, and fit for purpose for decades to come.

These extra costs nearly always include:

- Fire Protection: As demanded by UK Building Regulations, most mezzanines need at least 60 minutes of fire resistance. This means cladding columns, protecting the ceiling, and sometimes adding fire-rated fascias.

- Building Control Application: You have to submit your plans for approval, which involves a fee paid to either your local authority or an approved inspector. It’s a mandatory step.

- Professional Services: This covers the detailed structural calculations and drawings produced by engineers and designers, which prove the mezzanine is safe and compliant.

Making a Smart Investment

The good news is that a mezzanine floor delivers a surprisingly quick and substantial return on investment. The UK's mezzanine sector is growing steadily, with a projected CAGR of 5.7% through 2035, and it's all driven by clear financial benefits. Pricing data shows that a standard rack-supported mezzanine might cost between £100-£250 per square metre, but the payback period is often just two to three years, thanks to the massive boost in operational capacity or higher rental yields it provides. You can find more insights into the mezzanine floor market and its growth.

To make sure you get the best value, focus on optimising the design for material efficiency. For instance, working with your supplier to create a smart column grid can reduce the amount of steel needed without ever compromising on strength. By getting your head around all the elements that make up the final price, you can make an informed decision that adds real, long-term value to your business.

The Mezzanine Installation Process From Start to Finish

It’s easy to think of a mezzanine installation as just the on-site build, but that’s only a fraction of the story. The journey from an empty space to a fully functional new floor is a highly organised process, fine-tuned to be as efficient as possible while hitting the highest standards for safety and quality.

The real work begins long before the first steel column arrives. A professional installation follows a clear, structured timeline. Everything is planned, approved, and fabricated before the construction team ever steps foot on your site. This methodical approach is the secret to minimising disruption to your day-to-day operations.

The Four Key Project Phases

A typical mezzanine project unfolds in four distinct stages. Each phase has its own timeline and critical tasks that must be ticked off before moving to the next, which keeps the entire project flowing smoothly and predictably.

Consultation and Site Survey: It always starts with a detailed chat about what you need. This is followed by a thorough on-site survey where a specialist assesses your building’s structure, takes precise measurements, and spots any potential challenges like access points or existing pipework.

Detailed Design and Approval: Using the survey data, the design team gets to work creating detailed technical drawings and structural calculations. This is where your mezzanine is properly engineered to handle specific load capacities and comply with all UK Building Regulations. These plans are then submitted for formal approval.

Off-Site Fabrication: Once the design gets the green light, all the core components—steel columns, beams, purlins, and staircases—are manufactured to exact specifications in a controlled factory environment. This off-site work is vital for quality control and dramatically cuts down on the time, mess, and noise on-site.

On-Site Installation: Finally, the finished parts are delivered to your premises. A skilled installation crew assembles the structure quickly and efficiently, following a strict health and safety protocol to ensure a secure build with minimal impact on your business.

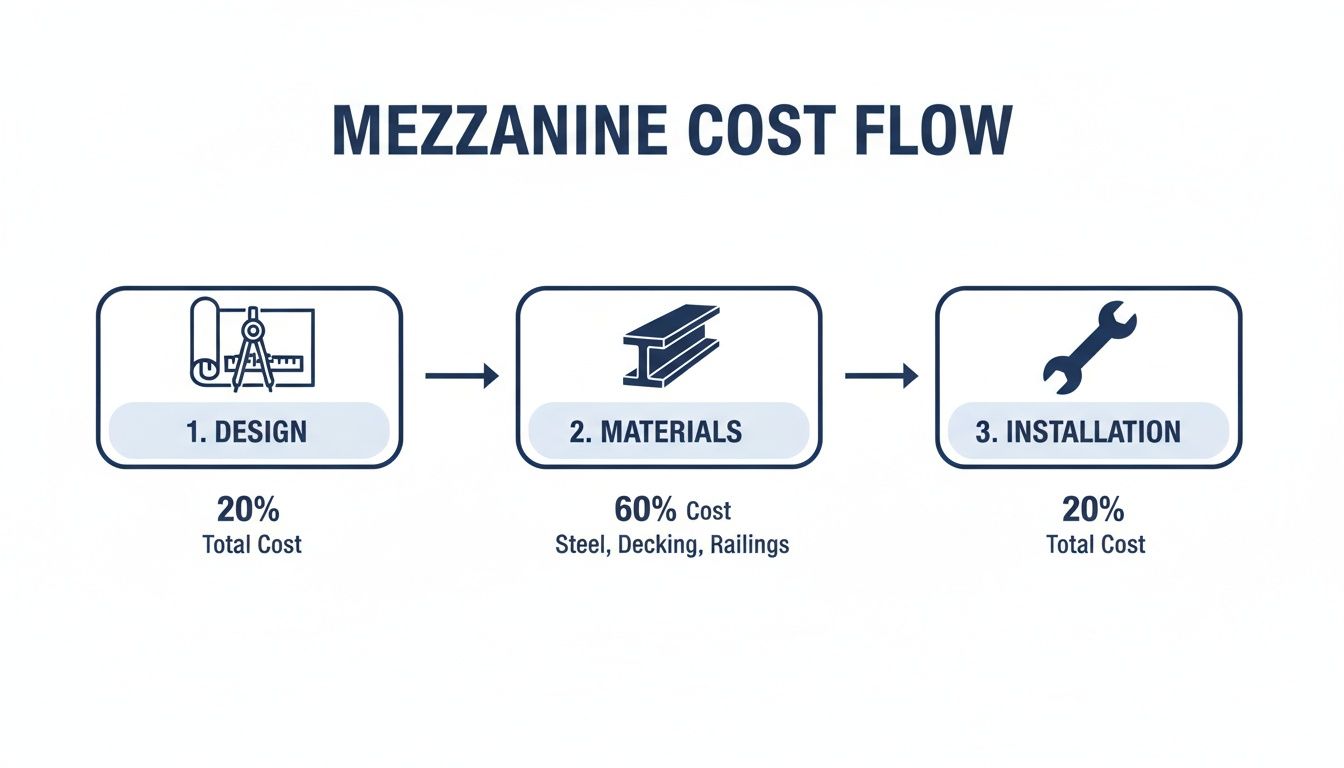

This diagram helps visualise how the project budget typically breaks down across the different phases.

As you can see, the bulk of the investment is in high-quality materials. The design and installation phases are smaller slices of the pie but are just as critical to the project's success.

Choosing Your Service Model

When it comes to getting your mezzanine built, you generally have two main service models to choose from. Each offers a different level of involvement.

A turnkey solution, often called a 'supply-and-fit' contract, is the most popular and hassle-free option. With this approach, a single company manages the entire process for you—from the initial survey and design right through to manufacturing, sorting out regulatory approvals, and final installation. It simplifies project management and gives you a single point of contact and responsibility. To see what this involves, take a look at our guide on the mezzanine manufacture and installation process.

The alternative is a 'labour-only' contract. This might be an option if you've already had the design done and sourced the materials yourself and just need an expert team for the assembly. For most businesses, however, the turnkey model provides the peace of mind and end-to-end expertise needed for a successful outcome. By understanding these steps and options, you can set realistic expectations and confidently oversee your project from start to finish.

How to Choose the Right Mezzanine Floor Supplier

Choosing your partner for a mezzanine project is arguably the most critical decision you'll make. The right supplier does more than just sell you a structure; they become your expert guide, navigating the maze of design, regulations, and installation to deliver a high-performing asset.

Get this choice right, and your project will run smoothly, resulting in a safe, compliant, and genuinely valuable addition to your facility.

It’s tempting to just look at the bottom line, but looking beyond the initial quote is essential. While cost is always a factor, the cheapest price rarely equals the best value. A supplier’s expertise, the quality of their materials, and a proven track record are far more important indicators of a successful outcome. The real goal is to find a partner who will deliver a robust solution that guarantees long-term performance and a strong return on your investment.

Vetting Potential Suppliers

When you start evaluating potential partners, your focus should be squarely on their proven experience and technical capability. Don't be shy about asking detailed questions that reveal their depth of knowledge and how they manage projects. This is your due diligence phase, and it’s vital for protecting your investment.

A great starting point is to look for a company that specialises in mezzanine floors UK projects and can show you a history of success, especially within your industry. Whether you're in retail, self-storage, or industrial warehousing, a supplier with relevant experience will already understand your unique operational challenges and requirements.

Key Questions to Ask Every Supplier

To properly size up a company, you need to dig into the specifics of what they offer. A reputable supplier will welcome these questions and give you clear, confident answers. Use this checklist as a guide during your initial conversations:

- Do you have an in-house design team? A supplier with their own designers can create a truly bespoke solution tailored to your space, rather than trying to make a one-size-fits-all approach work.

- How do you manage Building Regulations approval? The best suppliers handle the entire application process for you, submitting all the necessary structural calculations and drawings on your behalf. This takes a huge weight off your shoulders.

- Can I see your project portfolio and speak to past clients? Reviewing their previous work and hearing directly from other customers is the best way to verify their claims about quality and service.

- What accreditations do you hold? Look for certifications like CE/UKCA marking for structural steel. This isn't just a nice-to-have; it's a legal requirement and a clear mark of quality and safety.

A supplier’s ability to manage the entire process, from the initial site survey right through to the final sign-off, is a strong indicator of their professionalism. They should make a complex project feel straightforward for you, the client.

Look for Comprehensive Aftercare

Finally, think about what happens after the installation crew packs up and leaves. A trustworthy partner will offer comprehensive aftercare and support.

This includes providing detailed documentation for your health and safety files, offering guidance on maintenance schedules, and being available to answer any questions down the line. This long-term commitment is the sign of a supplier who stands by their work and is genuinely invested in your success.

Your Mezzanine Questions, Answered

Even with the best-laid plans, a few questions always pop up before you commit to a big project like a mezzanine floor. Here are some direct, no-nonsense answers to the queries we hear most often from clients across the UK.

Getting these details sorted will help you move forward with complete confidence.

How Long Will the Installation Take?

This is a great question, and the answer has two parts. The on-site build for a standard mezzanine (think 100-200 square metres) is surprisingly quick, often taking just 5 to 10 working days.

But the full project timeline, from our first chat to the final handover, is typically between 6 and 10 weeks. This longer lead time is crucial because it covers all the essential prep work that guarantees a smooth, compliant, and hassle-free installation. This includes the detailed site survey, creating structural designs, getting Building Regulations approval, and fabricating all the steelwork off-site. A good supplier manages this whole process for you, keeping any disruption to your business to an absolute minimum.

Do I Need Planning Permission?

In almost every case, the answer is a straightforward no. Because mezzanine floors are installed inside your building and are considered demountable structures, they don't change the external appearance. That's what planning permission is primarily concerned with.

However—and this is the important part—you will almost certainly need Building Regulations approval. This is a totally separate process that focuses on making sure the new structure is safe, structurally sound, properly fire-rated, and accessible. Planning permission only tends to become a factor in very specific situations, like if you’re in a listed building or the mezzanine dramatically increases your public retail space. Your supplier will be able to give you clear guidance on this from the start.

It's a common point of confusion, but vital to get right. As a rule of thumb, you won't need planning permission, but you will always need full Building Regulations approval for a commercial mezzanine floor anywhere in the UK.

What’s the Lifespan of a Mezzanine Floor?

A professionally designed and installed steel mezzanine is built to last. It’s a serious long-term asset for your business. The core steel structure, when built to strict standards like BS EN 1993 and properly looked after, is engineered to have a lifespan of 50 years or more.

Of course, some components, like the particle board decking, might need replacing over the years depending on how much foot traffic and heavy use it gets. But the fundamental framework is incredibly durable. The key to ensuring its safety and longevity for decades to come is simple: stick to the specified load limits and carry out regular inspections.

Can a Mezzanine Be Installed in a Fully Operational Warehouse?

Yes, absolutely. This is something experienced installation teams are experts at. The whole process is meticulously planned to work around your live operations, keeping disruption to an absolute minimum so your business can carry on as usual.

How do they do it? A huge part of the work—the fabrication of the steel components—happens off-site, which dramatically cuts down on noise, dust, and mess in your facility. The on-site build is often phased, with work areas safely cordoned off from your staff. Installers will work with your team to schedule any noisier activities during off-peak hours or downtime, all guided by a rock-solid health and safety plan.

Ready to unlock your building's full potential? The team at Partitioning Services Limited has over two decades of experience delivering end-to-end mezzanine floor solutions. Contact us today for a no-obligation consultation.

Looking for help with your next project?

Whether you are new to self storage or already have an established self storage facility, we can provide you with guidance and a full quotation for any aspect of your works.