Warehouse mezzanine flooring isn't just a structural addition; it's a savvy investment that unlocks the hidden vertical potential of your building. Think of it as adding a brand new, highly profitable floor—without the eye-watering costs and lengthy timelines of traditional construction. It’s all about turning that empty overhead space into a valuable, revenue-generating asset.

Unlocking Your Warehouse's Hidden Profit Potential

For self-storage developers and facility operators, the name of the game is maximising rentable square footage within a fixed footprint. It’s a constant commercial challenge. Every cubic metre of empty air above your head represents lost revenue, pure and simple.

This is exactly where warehouse mezzanine flooring proves its worth. It’s more than just steel and decking; it's a powerful tool for financial optimisation.

By installing a mezzanine, you can effectively double the usable floor area in high-ceilinged spaces. This new level can then be configured for a whole host of profitable uses, each one directly boosting your bottom line.

From Empty Space To Tangible Assets

The transformation is surprisingly straightforward but incredibly impactful. Just think about the possibilities for a self-storage business.

- Additional Storage Units: This is the most direct application. A mezzanine can support a full range of unit sizes, instantly increasing your rental inventory and monthly income.

- Operational Hubs: You could dedicate the new mezzanine level to operational needs—think a packing supplies shop, a reception area, or administrative offices. Doing this frees up the entire ground floor for premium, easily accessible storage units that command higher rates.

- Enhanced Facility Services: That extra space could even house value-added services, like a business centre for clients or secure document storage, creating entirely new revenue streams you didn't have before.

This approach lets you sidestep the significant capital expenditure, planning permission headaches, and long construction schedules that come with extending a building's physical footprint. It’s a much faster, more agile way to scale your operation. For a deeper dive, understanding how smart design impacts storage facility profits is crucial for getting the most out of this potential.

A well-designed mezzanine isn’t just about adding space; it's about engineering profitability. It allows you to increase rental income significantly while keeping your overheads relatively stable, dramatically improving your facility's overall return on investment.

To give you a clearer picture, here’s a quick summary of the main advantages for self-storage operators.

Key Benefits of Mezzanine Flooring for Self-Storage

| Benefit | Impact on Self-Storage Operations |

|---|---|

| Space Maximisation | Doubles usable floor area without expanding the building's footprint, turning vertical space into profitable rental units. |

| Cost-Effectiveness | Far cheaper and faster than traditional construction, avoiding major capital outlay and lengthy planning permission processes. |

| Increased Revenue | More rentable units and the potential for new services (e.g., business centres) directly translate to higher monthly income. |

| Operational Flexibility | The new level can be used for storage, offices, or retail, freeing up prime ground-floor space for premium units. |

| Rapid ROI | The lower initial cost and immediate revenue increase lead to a much quicker return on investment compared to building extensions. |

Ultimately, the goal is to convert every part of your building into a productive, income-generating asset.

While mezzanine flooring is a game-changer for space utilisation, other upgrades can complement your expansion and boost efficiency even further. For instance, exploring high-speed doors for enhanced warehouse efficiency and cost savings can improve security, climate control, and workflow.

This guide provides a practical framework for turning your warehouse's thin air into your next big competitive advantage.

A Building Within a Building: What Exactly Is a Mezzanine Floor?

So, what is a warehouse mezzanine floor? The easiest way to picture it is as a freestanding, semi-permanent 'building within a building'. It's a clever structure that carves out a brand-new, usable level from the empty vertical space in your warehouse—space that would otherwise be wasted air.

Unlike a permanent structural floor that becomes part of the building itself, a mezzanine is engineered to stand on its own two feet, so to speak. This is a game-changer for self-storage developers because it brings a level of speed and cost-efficiency that traditional construction just can’t touch. It’s simply a faster, smarter way to grow your rentable area.

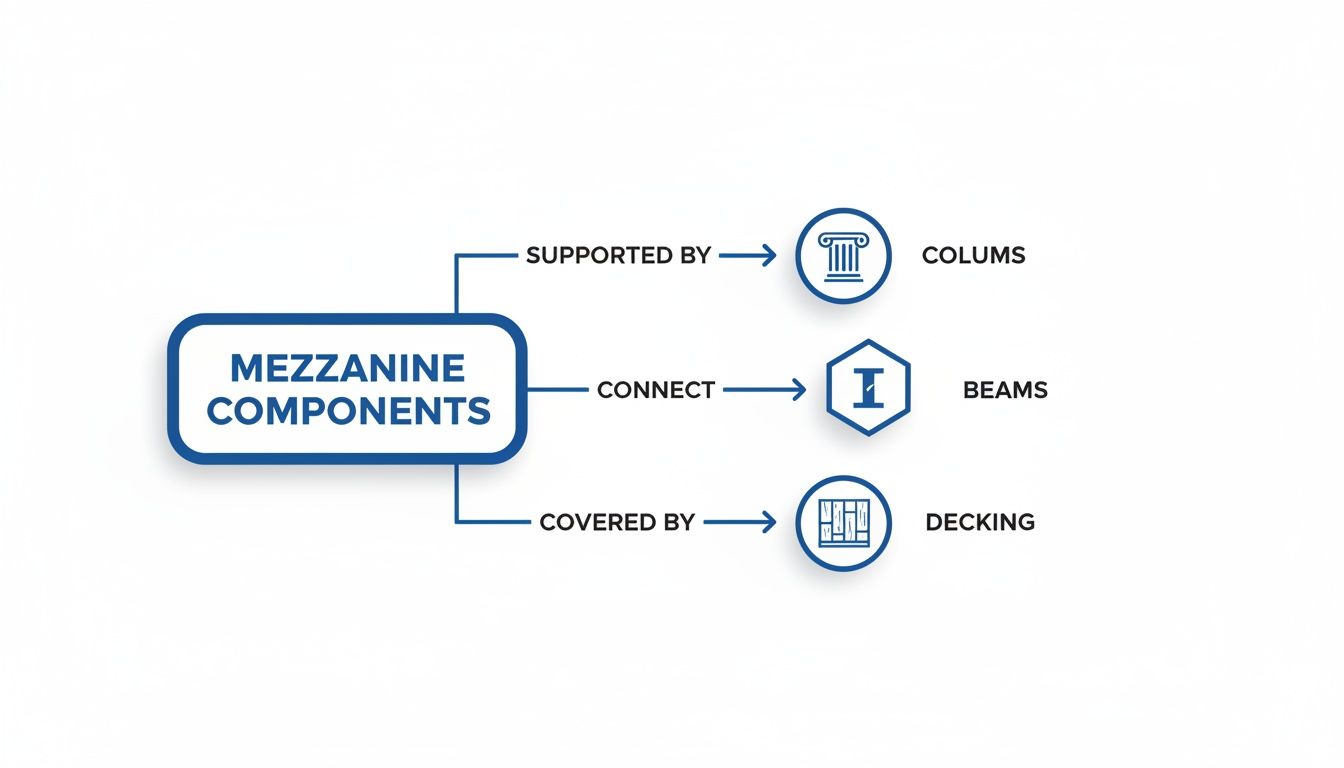

The Core Components Explained

A mezzanine’s strength comes from just a few key components working together. You don’t need an engineering degree to get your head around how it all fits.

- Columns: Think of these as the legs. They are the vertical steel pillars that transfer the entire weight of the mezzanine and everything on it safely down to the warehouse’s concrete slab.

- Beams: These are the primary horizontal steel sections connecting the columns. They form the main skeleton of the new floor, providing the core strength.

- Purlins or Joists: Running between the main beams, these smaller steel sections create a dense grid. This grid offers secondary support and creates the frame for the decking to sit on.

- Decking: This is the actual floor you walk on. It’s typically made from high-density particle board, but you might also see steel chequer plate or composite materials, depending on what it's being used for.

Put them all together, and you get a seriously robust platform ready to support anything from long corridors of storage units to operational office space. You can learn more about the specifics of our mezzanine floors and see how we tailor them for self-storage facilities.

Different Types for Different Needs

Not all mezzanines are built the same. The right choice for your facility really comes down to your operational goals.

The freestanding mezzanine segment holds a dominant 38.6% revenue share in the UK, prized for its flexibility and reusability—critical advantages for dynamic self-storage and warehousing needs.

This preference for freestanding systems is hardly a surprise. The UK's mezzanine market is set to grow, pushed by soaring demand from sectors like e-commerce, which saw online sales rocket to £118.9 billion in 2023. This immense pressure to squeeze value from every square foot makes adaptable solutions like mezzanines essential. You can find more insights about these market trends on futuremarketinsights.com.

For self-storage, there are three main types you'll come across:

- Freestanding Mezzanines: This is by far the most common and versatile choice. It’s a completely independent structure held up by its own columns, which makes it easy to install, modify, or even take with you if your business relocates.

- Rack-Supported Systems: With this design, the mezzanine floor is actually supported by the pallet racking system underneath it. It’s a smart way to combine high-density storage on the ground floor with picking areas or walkways on an upper level.

- Structural Mezzanines: These are the heavyweights. They are fully integrated into the building’s main structure, becoming a permanent addition. They often demand more extensive foundation work and planning approvals, making them a less common choice for agile expansion projects.

For the vast majority of self-storage developers, the freestanding model strikes the perfect balance of performance, cost, and flexibility.

Navigating Critical UK Design and Safety Regulations

Installing a mezzanine floor is far more than a simple construction job. It's a serious commitment to safety and legal compliance. Here in the UK, that means navigating a strict set of regulations designed to protect your staff, customers, and your investment. Let me be blunt: getting this right is non-negotiable. Treating compliance as an afterthought is a surefire recipe for costly delays and significant legal trouble down the line.

It helps to think of these regulations not as obstacles, but as the blueprint for a safe, efficient, and legally sound structure. They ensure your mezzanine is fit for purpose and, more importantly, a secure environment for everyone. The two main pillars of compliance you'll need to focus on are the UK Building Regulations and the relevant British Standards (BSI).

Understanding Core UK Building Regulations

Building Regulations are the legal requirements for designing and constructing buildings in the UK. When you install a mezzanine, you are fundamentally changing the interior of your warehouse, which brings several key parts of these regulations into play. For a deeper dive into what this means on the ground, you can explore our detailed guide on how to approach Building Regulations.

For any mezzanine project, the most critical areas of focus are:

- Part A (Structure): This ensures the mezzanine is structurally sound. It must safely bear its intended loads without failing or compromising the main building's integrity.

- Part B (Fire Safety): This governs everything from fire detection and escape routes to the use of fire-retardant materials. The goal is to ensure people can evacuate safely in an emergency.

- Part K (Protection from Falling): This details the mandatory requirements for barriers, handrails, and edge protection to prevent falls from height.

- Part M (Access to and Use of Buildings): This covers accessibility, making sure people with disabilities can safely get to and use the new level.

Ignoring these can lead to the local authority halting your project or even demanding you dismantle the entire structure. It’s just not worth the risk.

This diagram shows the main structural components that have to be designed and installed to meet these exacting standards.

Every single element plays a crucial role. From the columns transferring weight down to the ground, to the beams creating the frame, right up to the final decking—it all has to work together for total structural safety and compliance.

Calculating Correct Load Capacities

One of the single most critical design considerations is load capacity. This isn’t a ballpark figure; it’s a precise calculation that determines how much weight your mezzanine floor can safely handle. Getting this wrong is a catastrophic risk. You must be crystal clear about how the space will be used from day one.

A mezzanine designed for light office use will have vastly different structural requirements from one intended to hold rows of self-storage units filled with heavy goods. A standard office floor might be designed for 2.5-5.0 kilonewtons per square metre (kN/m²), whereas a storage mezzanine could require 7.5 kN/m² or significantly more.

Under-engineering the floor to save a bit on the initial quote is a dangerously false economy. On the flip side, over-engineering means you’ve simply spent more on steel than you needed to. A professional supplier will work with you to calculate the precise load rating for your specific self-storage application, hitting that sweet spot between safety and cost-efficiency.

Designing Safe and Compliant Access

How people get on and off your mezzanine is governed by very strict rules. Part K and Part M of the Building Regulations dictate everything about your access solutions, from the angle of the stairs to the need for accessible lifts.

Key access design points include:

- Staircase Design: The pitch, tread depth, and riser height of staircases are all specified. For general access stairs (Part K), the pitch must be between 38 and 42 degrees to ensure a safe and comfortable climb.

- Handrails and Guarding: Continuous handrails are mandatory on both sides of the staircase. The top of the mezzanine must have robust edge protection, including a top rail, a knee rail, and a kick plate at floor level to stop items from being accidentally pushed over the edge.

- Accessibility (Part M): If the mezzanine is for public access or for employees where access can't be restricted, you must provide an accessible way up. This almost always means installing a platform lift.

Integrating Essential Fire Safety Measures

Fire safety is arguably the most heavily scrutinised part of any mezzanine installation. A new floor level fundamentally changes how a fire could behave and how people can escape. Because of this, Part B of the Building Regulations demands a comprehensive fire safety strategy.

This strategy often involves several key elements working together:

- Fire Rating: If a mezzanine is over a certain size or covers a certain percentage of the building's floor area, it might need to be fire-rated. This usually means cladding the underside with fire-resistant materials to provide 60 minutes of protection, giving people time to escape and the fire brigade time to respond.

- Escape Routes: You must maintain clear, protected escape routes. The travel distance from any point on the mezzanine to the nearest fire exit must be within specified limits.

- Detection Systems: The installation may require you to extend your existing fire alarm and smoke detection system to cover the new level, ensuring early warnings are triggered in case of a fire.

Navigating these regulations requires specialist knowledge. A reputable turnkey provider will manage the entire compliance process for you, from submitting calculations to the local authority to ensuring the final build is signed off by a building control officer. This gives you peace of mind that your warehouse mezzanine flooring project is safe, legal, and built to last.

Calculating Your Mezzanine Cost and Return on Investment

Beyond the engineering and compliance, the question every self-storage developer really wants answered is simple: what’s this going to do for my bottom line? A warehouse mezzanine floor isn’t just a structural upgrade; it's a strategic investment designed to generate more revenue. To build a solid business case, you need to look past rough estimates and create a clear model for both the initial outlay and the long-term returns.

This means a detailed breakdown of all the costs involved, which go well beyond just the steel and decking. A truly comprehensive budget accounts for every stage of the project, so there are no nasty surprises down the line.

Breaking Down the Project Costs

The final price tag for a mezzanine is driven by a few key factors, with size and load capacity being the biggest. It stands to reason that a floor designed to hold heavy pallets will need far more substantial steelwork than one just for light administrative use.

But a realistic budget must also factor in the essential extras that make the space functional, safe, and compliant.

- Design and Engineering: This covers the initial site survey, all the structural calculations, and the creation of detailed drawings needed for fabrication and Building Regulations approval.

- Materials and Fabrication: This is the core cost of the steel itself—the columns, beams, and purlins—along with the high-density particle board decking.

- Installation Labour: You're paying for a skilled team to erect the structure on-site, safely and efficiently.

- Ancillary Features: This bucket includes mandatory safety gear like staircases, handrails, and edge protection, plus any goods lifts or pallet gates you need.

- Fire Protection: If required, you'll need to budget for fire-rating the mezzanine structure (which usually means cladding the underside) to achieve 60-minute fire resistance.

- Finishing Touches: Don’t forget the essentials like lighting, electrical wiring, and any partitioning needed to create individual storage units or offices.

As a general rule of thumb, a basic storage mezzanine might set you back between £90 to £140 per square metre. Of course, this figure will climb depending on the complexity and final specifications.

Modelling Your Return on Investment

Once the costs are clear, you can start modelling the return. For a self-storage business, the primary driver of ROI is simple: creating new, rentable square meterage from thin air.

Let's walk through a practical example to see how powerful the numbers can be.

Case Study: The 500m² Facility

Imagine you have a warehouse with a 500m² footprint and enough ceiling height to play with. By installing a 500m² mezzanine, you have instantly doubled your rentable area to 1,000m² without a single bit of external construction.

If your average rental rate is £250 per square metre per year, that new level represents an additional £125,000 in potential annual revenue. If the total project cost came in at £180,000, the simple payback period is just over 17 months. From that point on, the mezzanine becomes a pure profit-generating machine.

This isn't just theory. A real-world project for Navitas Circuit Protection in South Wales saw a custom warehouse mezzanine floor boost their usable space by a massive 82%, solving a critical space crunch. With UK industrial rents on the rise, it’s not uncommon for mezzanines to pay for themselves in just 12-18 months by adding capacity and helping businesses avoid the huge cost of relocating. You can discover more about this trend and other warehouse design insights.

Exploring Smart Funding Options

For many developers, the biggest hurdle to unlocking this new revenue is the upfront capital. The good news is, you don’t necessarily need to fund the entire project from your cash reserves. Structured finance packages offer a much smarter alternative.

These leasing or hire purchase agreements let you spread the cost of the mezzanine over a fixed term, typically three to five years. The real beauty of this approach is that the new floor starts generating rental income straight away—income that can cover, or even exceed, the monthly finance payments. It effectively makes the project self-funding, allowing you to expand your facility and boost revenue without a significant hit to your cash flow.

Choosing the Right Installation Partner for Your Project

The success of your warehouse mezzanine flooring project doesn't just hang on the quality of the steel; it hinges on the expertise and reliability of the partner you choose to bring it to life. This is one of the most critical decisions you'll make, and it will directly shape your project's timeline, budget, and final quality.

Getting this right means a smooth, predictable process. The wrong choice? That’s a recipe for costly delays, budget blowouts, and compliance headaches.

You’re not just hiring an installer; you're deciding on the entire delivery model for your investment. This choice really boils down to two distinct approaches, and each comes with its own set of responsibilities and risks. Understanding the difference is key to aligning the project with your business's capabilities and your appetite for risk.

The Turnkey Supply and Fit Model

The turnkey or supply-and-fit model is the all-in-one, end-to-end solution. Think of it as hiring a specialist project manager who handles absolutely everything for you. From the initial site survey and structural calculations to navigating Building Regulations, fabricating every component, and managing the on-site installation, a single partner takes full ownership.

This approach is designed to be completely hands-off for you, the developer. Your provider becomes the single point of contact and accountability, coordinating all the moving parts. It dramatically cuts down your administrative burden and almost eliminates the risk of miscommunication between different contractors.

The Labour Only Contract Approach

In contrast, a labour-only contract is exactly what it sounds like. You’re hiring a team purely for their installation skills. With this model, you take on the full responsibility of sourcing and procuring all the materials yourself—the steel beams, columns, decking, fixings, the lot.

This route can be tempting for developers who have strong relationships with material suppliers or believe they can source components more cheaply. However, it places the full weight of project coordination, quality control, and logistics squarely on your shoulders. You’re the one responsible for making sure the right materials arrive on time and are fit for purpose.

Choosing a partner is about more than just installation; it’s about entrusting a critical part of your business expansion to a team that understands the nuances of creating a safe, compliant, and profitable space.

To help you figure out which path is right for your project, let’s break down the two models side-by-side.

Comparing Mezzanine Installation Models

Deciding between a turnkey and a labour-only approach comes down to how much risk and project management you’re willing to take on. This table lays out the key differences to help you make an informed choice.

| Aspect | Turnkey (Supply-and-Fit) | Labour-Only |

|---|---|---|

| Project Management | Handled entirely by the partner. Single point of contact. | Your responsibility. You coordinate designers, suppliers, and installers. |

| Risk & Liability | Partner assumes most of the risk for material quality and timelines. | You assume all risk for material procurement and logistics. |

| Cost Structure | A single, all-inclusive price covering design, materials, and labour. | Separate costs for materials, design, and installation labour. |

| Timeline Control | More predictable as one partner controls the entire schedule. | Dependent on your ability to manage multiple suppliers and deadlines. |

Ultimately, the best choice depends entirely on your internal resources, experience, and how hands-on you want to be. For most developers, the turnkey model provides the peace of mind and expert oversight needed to deliver a successful warehouse mezzanine flooring project on time and within budget.

When you're selecting a partner, understanding what goes into a successful build is paramount. For some extra reading on the topic, this guide on Commercial Flooring Installation Done Right offers some really valuable insights.

Your Essential Mezzanine Project Checklist

Putting a mezzanine floor into your warehouse can feel like a massive undertaking, but with a solid plan, it's a completely manageable and predictable process. Think of this checklist as your project roadmap—it’s here to guide you through every critical stage, from the initial idea to the final sign-off.

Following these steps will help you make smarter decisions, choose the right partners, and ensure your project delivers exactly what you need, on time and on budget.

Phase 1: Nailing Down Your Needs and Checking Feasibility

Before you even think about picking up the phone to a supplier, you need to be crystal clear on what you’re trying to achieve. This first phase is all about defining your operational needs and understanding the physical limits of your building. Get this right, and you'll sidestep costly changes down the line.

-

Define the Purpose: Be specific. Is this new level for extra self-storage units, a few admin offices, or a combination of both? The intended use is the single biggest factor determining the required load capacity, which directly impacts the design and cost.

-

Measure Your Space: Get the tape measure out. You need accurate measurements for the length, width, and—most importantly—the clear internal height of your warehouse. This will tell you the maximum footprint and headroom you can work with.

-

Check Your Slab: Your concrete floor has to be strong enough to take the point loads from the mezzanine columns. Don't be surprised if a potential supplier wants to take a core sample to check its depth and strength. It's a standard and necessary step.

-

Map Out Access: Think about how people and goods will get on and off the new level. Where will the staircases, lifts, and pallet gates go? How will that affect the workflow you already have on the ground floor?

A well-defined brief is the bedrock of a successful project. Rushing this stage is a recipe for scope creep and budget blowouts. Take the time to get clear on your goals before you start talking to suppliers.

Phase 2: Vetting Suppliers and Analysing Quotes

With your brief ready, you can start the hunt for the right partner. The goal here isn’t just to find the cheapest price; it's to find a supplier with proven expertise in warehouse mezzanines and a transparent, professional approach.

When the quotes start coming in, make sure you're comparing apples with apples. A proper quote should be a detailed document, not a single-page estimate scribbled on the back of an envelope.

Insist on seeing the following in every quote:

- Detailed Scope of Works: A clear, itemised list of everything included—design, steel fabrication, delivery, installation, and final commissioning.

- Full Specification: This should spell out the type of steel being used, the decking material (e.g., 38mm P6 particle board), and all the extras like handrails and kick plates.

- Compliance Statement: The quote must explicitly state that the design will comply with all relevant UK Building Regulations (Parts A, B, K, and M). No ifs, no buts.

- Project Timeline: Look for a realistic schedule with key milestones, from drawing approval right through to the on-site installation dates.

Phase 3: Hitting Milestones and Final Handover

Once you've chosen your partner, the project moves into the delivery phase. Your job now is to keep an eye on progress against the agreed milestones and get ready for the handover. Stay involved and keep the lines of communication open with your supplier's project manager.

Key Monitoring Stages:

-

Drawing Approval: You’ll be sent detailed CAD drawings to sign off. Go over them with a fine-tooth comb to ensure they match what you asked for before any steel gets cut. This is your last real chance to make changes without it costing you a fortune.

-

Building Regulations Application: If you've gone for a turnkey partner, they should handle all of this. Ask for confirmation that the application has been submitted and approved, whether that's through the local authority or an approved inspector.

-

On-Site Installation: Before the installation crew turns up, make sure the area is completely clear and ready for them. Popping in for regular check-ins during the build will help you nip any small issues in the bud quickly.

-

Final Handover and Sign-Off: When the work is finished, do a walkthrough of the new mezzanine with the project manager. Check the quality of the finish and make sure you're handed all the important documents, especially the final Building Regulations completion certificate. That certificate is your proof that the structure is safe, legal, and built to standard.

Warehouse Mezzanines: Your Questions Answered

Even with a detailed plan, it’s natural to have a few questions buzzing around when you’re considering a mezzanine floor. We get it. Here are some clear, straight-to-the-point answers to the questions we hear most often from UK self-storage operators.

Do I Always Need Planning Permission for a Mezzanine in the UK?

Usually, no. Think of a freestanding mezzanine as a massive piece of equipment rather than a permanent change to the building itself. As long as it doesn’t tie into the main structure and stays within certain size limits, you generally won’t need planning permission.

However, you will always need Building Regulations approval. This is the one step you can’t skip. It’s the official certification that your new structure is safe and meets all the mandatory standards for fire safety, access, and structural strength. A good provider will handle this entire process for you, so you don't have to navigate the red tape alone.

How Long Does a Typical Mezzanine Floor Installation Take?

This is one of the best parts – the on-site build is incredibly quick. For a standard-sized mezzanine, the physical installation is often done and dusted within one to two weeks. This speed is a huge advantage, especially in a live facility, as it keeps disruption to an absolute minimum.

But remember, that’s just the on-site part. The whole project timeline includes a few crucial off-site stages that happen first:

- Initial design and site survey: 1-2 weeks

- Structural calculations and drawings: 1-3 weeks

- Fabrication of steelwork and decking: 3-6 weeks

A turnkey partner coordinates all these moving parts, giving you a smooth and predictable timeline from that first phone call to the final handover.

The real value of a turnkey partner is their ability to manage the entire process, from design and compliance to fabrication and installation, ensuring a smooth and predictable timeline. This integrated approach prevents delays caused by coordinating multiple separate contractors.

Can a Mezzanine Floor Be Moved or Modified in the Future?

Absolutely, and this flexibility is a major plus. The vast majority of warehouse mezzanines are built using a bolted steel construction, which means they are fully demountable.

You can dismantle the entire structure with relative ease, pack it up, and move it to a new facility. Or, if your needs change, you can simply reconfigure the layout within your current building. This adaptability protects your investment for the long haul, making sure the mezzanine continues to work for you as your business evolves.

At Partitioning Services Limited, we specialise in designing and installing high-quality, fully compliant warehouse mezzanine flooring tailored for the self-storage industry. Let us help you unlock your facility's true potential. Find out more at https://psllimited.co.uk.

Looking for help with your next project?

Whether you are new to self storage or already have an established self storage facility, we can provide you with guidance and a full quotation for any aspect of your works.