When you think of a warehouse racking company, what comes to mind? If it's just someone who sells shelves, it's time to think bigger. These companies are specialists who design, supply, and install the very backbone of your storage facility, transforming empty floor space into a highly functional asset that’s perfectly matched to your inventory and operational flow.

They’re less like a supplier and more like a strategic partner.

How Warehouse Racking Companies Transform Your Space

Think of a professional racking company as an architect for your inventory. Their job isn't just to sell you steel; it's to turn an underutilised area into a structured, productive environment that optimises your entire supply chain, from goods-in all the way to dispatch.

A professionally engineered racking layout goes far beyond simply stacking pallets higher. It creates a logical flow for picking and replenishment, which cuts down on the travel time for your staff and machinery. This boost in operational speed can lead to some serious savings.

Maximising Your Vertical Footprint

One of the most immediate wins is how they maximise your storage density. By making smart use of vertical space, you can dramatically increase your storage capacity without the eye-watering cost of moving or extending your building. This is exactly where solutions like robust commercial mezzanine floors can literally double your usable floor area.

The shift towards e-commerce has put huge pressure on warehouses to hold more stock and get orders out the door faster. It’s no surprise, then, that the UK warehouse racking market is projected to grow at a CAGR of 3.9%. This growth is being driven by the relentless need for these kinds of efficient storage solutions.

A Foundation for Efficiency and Safety

Beyond just squeezing more in, the right warehouse racking is fundamental to a leaner, more productive operation. By creating designated pathways and organised storage faces, it reduces congestion and massively improves inventory management. For a broader look, you can explore general strategies to reduce operational costs and boost efficiency across your business.

A well-designed racking system is the backbone of a safe and efficient warehouse. It doesn't just hold products; it directs workflow, protects inventory, and ensures your team can operate with confidence and precision.

Ultimately, partnering with specialist warehouse racking companies turns your storage area from a necessary cost into a genuine competitive advantage. It’s about setting your business up for future growth and whatever the market throws at you next.

Core Services That Define a Top-Tier Racking Partner

The best warehouse racking companies offer a lot more than just steel beams and uprights. They become genuine partners, guiding you through your project’s entire lifecycle. It’s this full-service approach that separates a mere supplier from a real expert—one who can deliver a safe, efficient, and future-proof storage system. This partnership is really built on three core pillars of service.

Design and Consultation

The journey always kicks off with a detailed consultation and design phase. This is much more than just measuring your floor space. A top-tier partner digs deep into your unique operational needs, looking at everything from inventory profiles and stock rotation methods (FIFO vs. LIFO) to the types of forklifts you use and your staff's daily workflows.

This initial analysis is absolutely critical for crafting a layout that’s truly bespoke and actually works for your business. The result isn't just a sketch; it's a highly detailed CAD drawing and a plan that maximises your storage density while guaranteeing smooth traffic flow and easy access for your team.

Professional Installation and Project Management

Once a design gets the green light, the focus shifts to supply and installation. A professional company manages this entire process, from sourcing high-quality, compliant materials to coordinating the delivery logistics. The installation itself is handled by certified teams who work to incredibly precise standards, ensuring structural integrity and unwavering safety.

This stage is completely non-negotiable for compliance and the long-term health of your system. Get it wrong, and you're looking at a potential catastrophe—endangering staff and wiping out inventory. Professional installers make sure every beam is level, every bolt is torqued correctly, and the entire structure meets strict industry regulations.

True value isn't just in the product, but in the end-to-end expertise. A racking partner invests in your operational success from the first sketch to the final safety check, ensuring the solution works seamlessly for years.

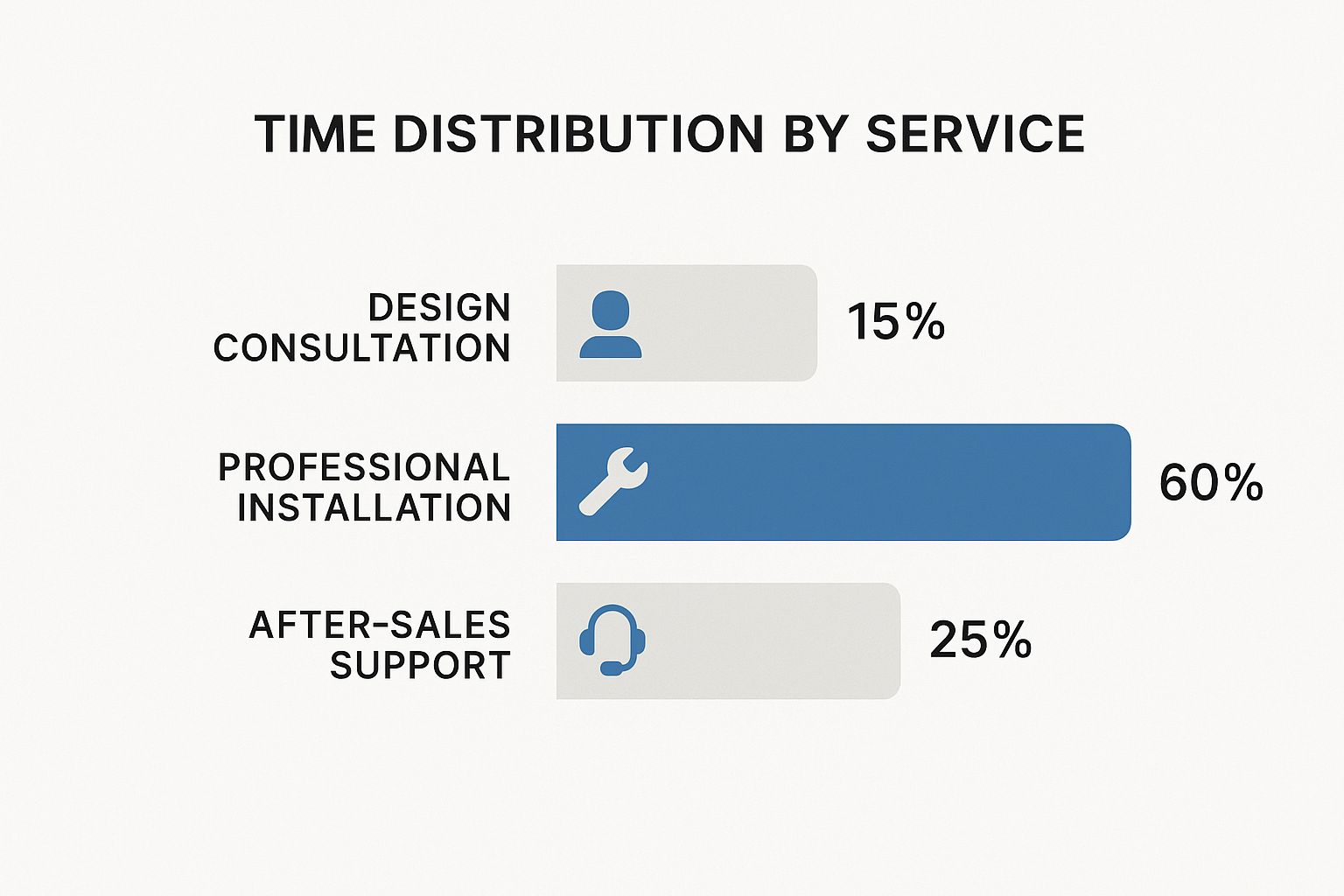

The infographic below shows how a project’s timeline is typically split across these core services.

As you can see, installation is the most intensive part, but a huge 25% of the partnership is dedicated to what happens after the build is complete.

Ongoing Support and Maintenance

The relationship doesn't end once the last bolt is tightened. Leading warehouse racking companies provide vital after-sales support to protect your investment. You could argue this is the most important long-term service, as it ensures your system remains safe and efficient day in, day out.

Key after-sales services usually include:

- SEMA-Approved Inspections: Regular, expert inspections are a legal requirement in the UK. They're designed to spot any damage or wear and tear before it becomes a serious hazard.

- Routine Maintenance: Proactive checks and servicing help extend the life of your racking and prevent the kind of costly downtime that no business can afford.

- Rapid Repairs: When damage does inevitably occur, a reliable partner offers quick and efficient repair services to get your system back to full strength with minimal disruption.

This long-term commitment is what guarantees your racking stays compliant, safe, and fully operational, giving you lasting value and, just as importantly, peace of mind.

Choosing the Right Racking System for Your Inventory

Picking the right racking system isn’t just about filling space—it’s about choosing the correct tool for a very specific job. A carpenter wouldn’t use a hammer for every task, and a warehouse manager needs to match their racking to their inventory’s unique quirks. The choice you make impacts everything, from picking speed and storage density to the entire flow of your operation.

Get it wrong, and you’re looking at daily frustrations and operational bottlenecks. But get it right, and the system becomes an invisible, hardworking asset. This is exactly why a proper chat with expert warehouse racking companies is so valuable. While they can guide you through the options, understanding the fundamentals yourself puts you firmly in control of the conversation.

The Versatile Workhorse: Selective Pallet Racking

Walk into most warehouses and you’ll likely see selective pallet racking. Think of it as the dependable multi-tool of the storage world. Its biggest advantage is simplicity and direct access; every single pallet is immediately available without having to shuffle others around.

This setup is perfect for businesses with a high variety of SKUs (Stock Keeping Units) but low quantities of each one. If your stock turnover is high and you need to get to different products in a hurry, selective racking delivers the flexibility you need. The trade-off, however, is that it offers lower storage density compared to other systems.

High-Density Solutions for Uniform Stock

When your warehouse is full of large quantities of the same product, squeezing the most out of every cubic metre becomes the top priority. This is where high-density systems like drive-in or drive-through racking really shine.

- Drive-In Racking: Forklifts drive directly into the racking structure to place or retrieve pallets. This system operates on a Last-In, First-Out (LIFO) basis, making it ideal for non-perishable goods or items with a long shelf life.

- Drive-Through Racking: It’s similar in structure but accessible from both sides, allowing for a First-In, First-Out (FIFO) stock rotation. This is crucial for products with expiry dates, like food and beverage items.

By getting rid of aisles, drive-in systems can boost storage capacity by up to 75% compared to standard selective racking. That makes them a powerful choice for cold storage or bulk goods facilities where space is at a premium.

Specialised Systems for Awkward Items

But what about items that just won’t play nice with a standard pallet? We’re talking about things like timber, steel pipes, or furniture. For these long, bulky, or oddly-shaped goods, cantilever racking is the purpose-built solution.

It features vertical columns with horizontal arms extending outwards, creating long, unobstructed shelves. This design gives you clear access for handling awkward items without the vertical posts of traditional pallet racking getting in the way. Of course, the layout is a key part of success, and understanding the principles of effective storage facility design is crucial for getting the most out of any system you choose.

By carefully looking at your inventory type, turnover rate, and operational flow, you can pinpoint the racking system that will not only store your goods but actively improve your business's productivity and bottom line.

How to Select the Best Racking Company

Choosing a partner for a major warehouse project is a big deal. It’s one of those decisions that will echo through your operations for years, affecting everything from your budget and efficiency to your team’s safety. Getting this right isn’t about chasing the cheapest quote; it’s about finding a true partner—someone with the skill to deliver a reliable, compliant system that’s built to last.

To do this, you need a structured approach. It’s time to look past the slick brochures and dig into what really matters. From industry credentials to their real-world track record, every detail counts when you’re trying to find the perfect fit for your business.

Verify Industry Credentials and Experience

Your first port of call should always be industry accreditation. In the UK, the gold standard is an affiliation with SEMA (Storage Equipment Manufacturers' Association). Frankly, this should be non-negotiable. It’s the clearest benchmark of quality and safety you’ll find.

A SEMA-affiliated company is signalling its commitment to designing, manufacturing, and installing systems that meet the highest possible industry standards. Think of it as your primary assurance that they are competent, professional, and completely up to speed with the latest health and safety regulations. Don't be shy—ask for proof of their membership and check it yourself.

Next, get a feel for their experience by diving into their portfolio. A reputable company will be more than happy to share case studies and client testimonials. Look for projects similar to yours in scale or complexity. Do they know your world, whether it’s the fast-paced environment of e-commerce fulfilment, the precise demands of cold storage, or the robust needs of manufacturing?

Evaluate Their Process and Material Quality

A professional on-site consultation is an absolute must. During this visit, a potential partner should be grilling you with detailed questions about your inventory, throughput, and future growth plans. They should be trying to get under the skin of your operation, not just measuring the four walls of the room.

This is your chance to turn the tables and ask them some critical questions of your own:

- What does your design and approval process look like from start to finish?

- Where do you source your steel and other materials?

- What kind of warranty do you offer on the installation and components?

- Who is managing the project, and will I have a single point of contact?

When the quotes start coming in, resist the temptation to let your eyes drift straight to the bottom line. A cheaper quote might be hiding lower-grade steel or shortcuts on installation, creating massive long-term risks. Always insist on an itemised breakdown that details everything from material specifications and labour costs to any extra services like safety inspections or training.

Choosing a racking partner is an investment in your company's operational backbone. The right decision delivers not just storage, but safety, efficiency, and a solid foundation for growth. An inadequate one creates daily risks and long-term costs.

The UK's role in the European logistics network is only getting bigger, driven by a booming e-commerce sector that lives and dies by highly efficient supply chains. This has pushed warehouse racking companies across the country to invest in better technologies and more robust solutions. As the market expands, picking a company with a proven track record is more crucial than ever. You can read more about the European warehouse racking market to get a better handle on these trends.

Making a careful, informed decision now will pay you back tenfold down the line, giving you a system that not only supports your business today but is ready for whatever tomorrow throws at it.

The Installation Process From Start to Finish

A professional racking installation should be a smooth, well-managed project, not a chaotic disruption to your business. While it might look complicated from the outside, the best warehouse racking companies follow a proven, structured timeline that clears up the mystery and sets realistic expectations right from the start.

This approach is all about ensuring a successful build with as little downtime as possible for your operations. The journey actually begins long before the first beam is slotted into place, starting with a meticulous pre-installation phase. This is where the real groundwork for a safe and efficient build is laid.

Laying the Foundation for Success

The pre-installation phase is all about planning and preparation. Think of it as a collaborative effort between you and your racking partner to nail down every single aspect of the project before the tools come out.

Key steps in this initial stage typically include:

- Final Site Survey: A technical team visits your facility to take precise measurements, check floor levels, and spot any potential obstacles like support columns or low-hanging sprinkler systems.

- Design Sign-Off: You’ll receive detailed CAD drawings of the proposed layout. This is your last chance to review everything and give the final thumbs-up before materials are ordered and manufacturing begins.

- Project Scheduling: A clear timeline is established, outlining start and completion dates. This schedule is carefully planned to work around your ongoing operations and keep disruption to a minimum.

This careful preparation is what prevents costly surprises and frustrating delays down the line. It means that when the installation team arrives on-site, they have a clear, approved plan and all the necessary components ready to go.

The Build and Handover

With all the planning locked in, the physical installation can get underway. Professional teams work methodically and efficiently, following the approved designs to the letter. Safety is the absolute priority here, with certified installers sticking to strict protocols and site-specific risk assessments. They’ll coordinate their work to ensure your daily operations can continue as safely as possible.

A successful installation is more than just assembly. It's a carefully orchestrated project that prioritises safety, precision, and clear communication, resulting in a system that is not only functional but fully compliant from day one.

Once the structure is fully erected, the project moves into the crucial post-installation and handover stage. This isn’t just about finishing the job; it’s about empowering your team to use the new system safely and effectively for years to come.

The handover process involves several key parts:

- Final Inspection: A thorough walk-through is carried out to ensure the installation meets all the design specifications and quality standards.

- System Commissioning: The system is officially commissioned, and all the necessary documentation, including load notices and safety certificates, is handed over to you.

- Staff Training: Your team gets essential training on safe operating procedures, daily checks, and how to spot and report any potential damage.

This comprehensive approach guarantees you receive a fully functional, safe, and compliant asset. If you want to dive deeper into how a project progresses from concept to completion, you can learn more about the specifics of racking manufacture and installation.

Your job isn’t finished once the racking is installed. Just like a car needs a regular MOT, your racking system needs consistent attention to stay safe, efficient, and legally compliant for its entire working life.

Think of it this way: proactive maintenance is the best way to protect your team, your stock, and your business. It all starts with simple, daily checks that your own trained staff can handle. These visual inspections are your first line of defence against damage that could otherwise escalate into something far more dangerous and costly.

The Role of Regular Inspections

Regular inspections fall into two crucial categories. First, you have the informal daily or weekly checks carried out by your warehouse team. These are the people on the ground, and they should be trained to spot obvious signs of trouble – a bent upright, a missing brace, or anything else that looks out of place.

Second, and most importantly, is the annual expert inspection. UK regulations are clear on this: a technically competent person must conduct a thorough inspection at least once every 12 months. Professional warehouse racking companies offer this as a core service. They’ll give you a detailed report that flags any risks and tells you exactly what needs fixing.

Ignoring racking damage is a gamble you can’t afford to take. A compromised upright doesn’t just fail on its own; it can trigger a domino effect, leading to a catastrophic collapse that endangers lives and grinds your operations to a halt.

Identifying and Managing Damage

The number one culprit for racking damage? Impacts from forklifts and other handling equipment. Even a knock that seems minor can seriously compromise the structural integrity of an upright or brace, slashing its load-bearing capacity.

Your team needs to feel empowered to report any damage they spot immediately, no matter how small it seems. You should have a clear, non-negotiable process for quarantining any affected bays. This usually involves:

- Reporting: The moment damage is seen, a supervisor or designated safety officer must be notified.

- Off-loading: All pallets must be carefully removed from the damaged section.

- Isolating: The area has to be clearly marked as out-of-use with signs and barriers until it's repaired.

Finally, always stick to the Safe Working Load (SWL) notices the installer provides. These aren't just suggestions; they are the absolute maximum weight the system is designed to hold safely. Overloading is a primary cause of structural failure, and it’s entirely preventable with proper training and management.

A Few Common Questions

Diving into the world of industrial storage can bring up a lot of practical questions. Getting straight answers is the best way to feel confident about investing in your facility's future. Here are a few of the most common things business owners ask when they start working with warehouse racking companies.

How Much Does Warehouse Racking Cost in the UK?

Honestly, the costs can swing wildly. It all depends on the type of racking you need, the current price of steel, how big your project is, and how complex the design gets.

Just to give you a rough idea, a standard selective pallet racking system might run you somewhere between £40 to £80 per pallet position. But if you’re looking at more specialised systems like drive-in or mobile racking, you can expect the price to be higher because of the intricate engineering involved. The best advice? Always get detailed, itemised quotes from a few reputable firms that break down the costs for design, supply, and professional installation.

What Is SEMA and Why Should I Care?

SEMA stands for the Storage Equipment Manufacturers' Association. Think of them as the main trade body for the UK storage industry, setting the gold standard for quality and safety.

Choosing a SEMA-affiliated company is your peace of mind. It’s a critical assurance that your racking’s design, manufacturing, and installation all meet the highest safety standards. It guarantees your system is fully compliant with current health and safety regulations, which protects your team and your investment.

Can I Just Install Second-Hand Racking Myself?

While it might look like a great way to save some cash, installing second-hand racking yourself is incredibly risky, and we strongly advise against it. Without an expert analysis, it’s nearly impossible to know the real history, true load capacity, or structural integrity of used components.

Professional warehouse racking companies make sure any system is correctly specified and installed to meet strict safety codes. The potential danger to your staff and your stock from a system failure is a massive risk that far outweighs any savings you might make upfront.

At Partitioning Services Limited, we deliver end-to-end, SEMA-compliant racking solutions designed for maximum safety and efficiency. To chat about your project with our expert team and get a detailed, no-obligation quote, find us at https://psllimited.co.uk.

Looking for help with your next project?

Whether you are new to self storage or already have an established self storage facility, we can provide you with guidance and a full quotation for any aspect of your works.