Warehouse storage solutions are the systems you use to organise your stock—everything from simple shelving to complex automated racking—to make your operation as efficient, safe, and profitable as possible. Think of them as more than just static racks; they're the very backbone of your facility, dictating how quickly you can get goods in, stored, and shipped back out.

Understanding Warehouse Storage as a Strategic Asset

It wasn’t long ago that a warehouse was seen as just a cost centre—a big, static box for holding goods. That thinking is now completely outdated. The seismic shift in consumer behaviour and the explosion of e-commerce have turned warehousing into the dynamic engine of the modern supply chain. For developers and operators, getting your head around this shift is non-negotiable.

A well-designed storage system isn't just a passive piece of the puzzle anymore; it's an active driver of your bottom line. Your choice of racking, the layout of your aisles, and the way your inventory flows have a direct impact on:

- Operational Efficiency: Slashing the time it takes for your team to find, pick, and pack orders.

- Space Utilisation: Squeezing the absolute maximum storage capacity out of your building's footprint.

- Profitability: Driving down labour costs, minimising product damage, and speeding up order fulfilment.

This strategic importance is why the sector is booming. The UK warehousing industry has grown massively, fuelled by the relentless rise of online retail. This growth just underscores the increasing demand for smarter, more efficient warehouse storage solutions. You can dig into the full research on the UK warehousing market growth at Ibisworld.

The Evolution from Storage to Fulfilment

The fundamental job of a warehouse has changed. It's no longer just about stacking pallets; it’s about fulfilling customer orders with lightning speed and pinpoint accuracy. This new reality demands a much more sophisticated approach to how we design these facilities.

A classic mistake is treating storage as an afterthought. An intelligent storage solution is the foundational framework that every other warehouse operation is built on. Get it right, and you create a high-performance asset. Get it wrong, and you build inefficiency right into your business model from day one.

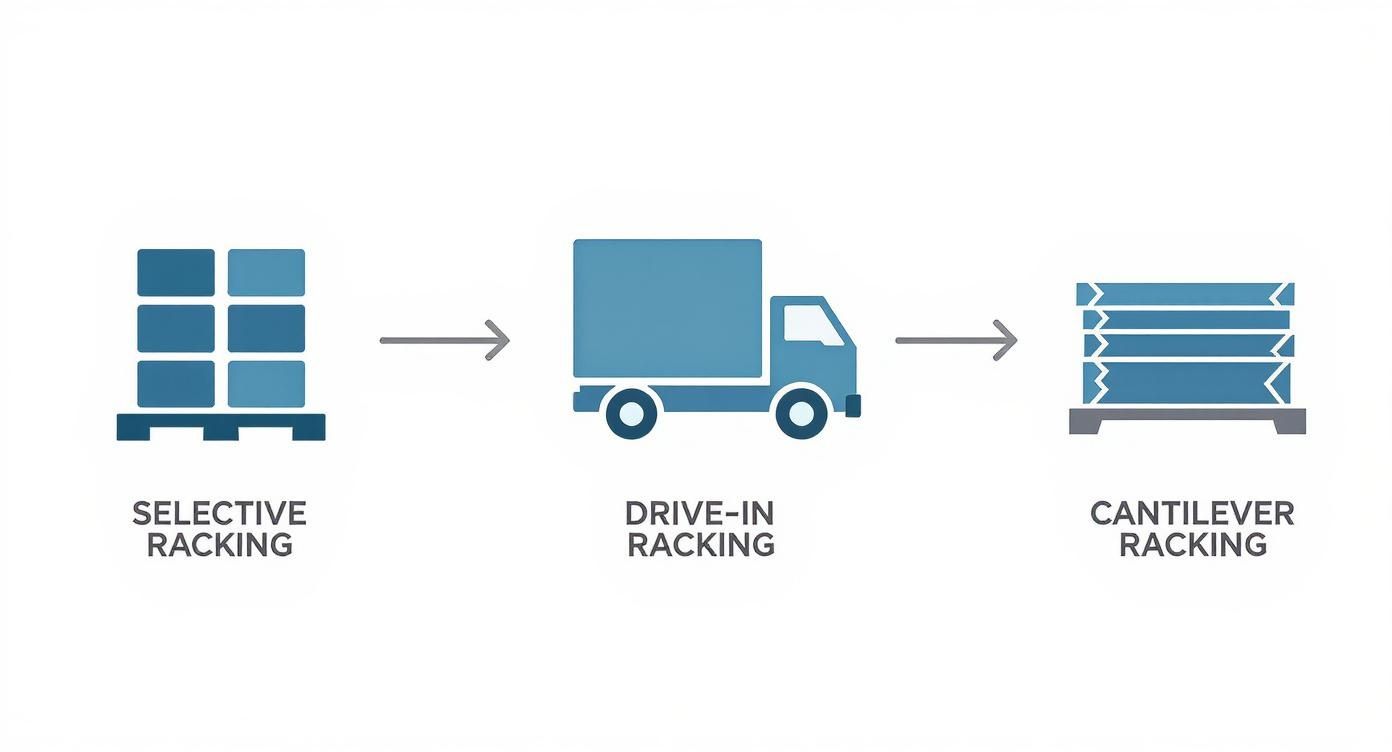

The image below gives you a sense of a typical modern warehouse, where the racking systems and material handling equipment work together to create a seamless workflow.

What this really shows is that the physical infrastructure—the racks, the aisles, the equipment—sets the entire operational rhythm of the facility. That’s why choosing the right systems from the very beginning isn't just a logistical decision. It's a critical business strategy that will define your facility's potential for years to come.

Choosing the Right Tools for the Job

Picking the right warehouse storage solution is a lot like a skilled tradesperson choosing tools from their toolbox. You wouldn't use a sledgehammer to hang a picture, and you definitely wouldn't use the wrong racking system for a specialised inventory. Each system is engineered for a specific task, and getting to grips with their unique strengths is the first step towards designing a truly efficient facility.

We're going to move beyond simple specifications and look at the real-world application of these essential systems. This isn't just about what they are, but what they do for your operation. Nail this choice from the outset, and you'll prevent costly redesigns and operational headaches down the line, which has a direct impact on your profitability.

The All-Purpose Workhorse: Selective Pallet Racking

Think of selective pallet racking as the adjustable spanner of the warehouse world. It’s the most common and versatile system out there, and for good reason. Its simple design gives you direct, individual access to every single pallet. This makes it perfect for operations with a high number of different product lines (or SKUs) where getting to things quickly is the name of the game.

This system is all about accessibility, not density. While it won't win any awards for being the most space-efficient option, its flexibility is second to none. You can easily adjust beam levels to handle changing pallet heights, and it works seamlessly with any standard forklift. For a developer, this system is a low-cost, adaptable foundation that suits a wide range of potential tenants with varied stock needs.

High-Density Solutions for Maximum Capacity

When your main goal is to cram as much storage as possible into a given footprint, high-density systems are the specialised tools you need. They pull this off by cutting down the number of access aisles, effectively trading individual pallet access for a massive boost in capacity.

Drive-In and Drive-Through Racking are classic examples. Imagine packing a suitcase for a long trip—you arrange everything tightly to use every last bit of space. Drive-in racking does the same with pallets. Forklifts drive straight into the racking structure to place or retrieve pallets, which sit on rails. This "last-in, first-out" (LIFO) setup is ideal for storing large quantities of identical, non-perishable goods.

- Drive-In Racking: Has a single entry and exit point, making it a strict LIFO system.

- Drive-Through Racking: Allows access from both ends, which enables a "first-in, first-out" (FIFO) workflow. This is crucial for goods with an expiry date.

These systems can ramp up your storage capacity by up to 85% compared to standard selective racking. That makes them a powerful choice for cold storage or bulk goods warehousing where every square metre counts.

Specialised Systems for Unique Challenges

Of course, not all inventory fits neatly onto a standard pallet. For long, bulky, or awkwardly shaped items like timber, piping, or furniture, you need a purpose-built solution. That's where cantilever racking comes in. It uses a central column with arms extending outwards to support loads, getting rid of the vertical posts that get in the way with traditional pallet racking.

This design gives you clear, horizontal access, making it dead simple to store and retrieve cumbersome items. It’s a perfect example of how a specialised tool can solve a common warehouse headache, preventing product damage and making handling much safer.

Choosing a storage system isn't just about fitting more in; it's about creating a smarter workflow. The right system reduces travel time for pickers, minimises handling, and protects the value of the inventory it holds.

Another powerful, specialised solution is mezzanine flooring. This is less a racking system and more of a structural upgrade. By installing a second or even third floor within the existing vertical space of your warehouse, you can effectively double or triple your usable square meterage. This new area can be used for extra storage, office space, or light assembly work, offering incredible ROI without the expense of extending the building's footprint.

To help you weigh the core options for your next project, here’s a quick comparison.

Comparing Core Warehouse Storage Systems

This table offers a quick-reference guide to the most common storage systems, breaking down what they’re best for, their density, how accessible your stock will be, and the relative cost.

| System Type | Best For | Storage Density | Stock Accessibility | Relative Cost |

|---|---|---|---|---|

| Selective Racking | High SKU counts & fast turnover | Low-Medium | High (100% access) | Low |

| Drive-In Racking | Bulk storage of uniform products | Very High | Low (LIFO) | Medium |

| Cantilever Racking | Long, bulky, or irregular items | Medium | High (for specific items) | Medium-High |

| Mezzanine Flooring | Maximising vertical space | N/A | High | High |

Each system has its place. The key is matching the tool to the specific operational challenges you or your future tenants will face. Getting this right is fundamental to a successful and profitable warehouse development.

Designing a High-Efficiency Warehouse Layout

Having the right racking systems is only half the battle; how you arrange them on the floor dictates the operational rhythm of your entire facility. A smart layout transforms a simple collection of racks into a high-performance logistics hub, optimising the flow of goods, people, and machinery. It’s the difference between a chaotic workspace and a finely tuned engine for profit.

The goal is simple: minimise travel time. Every extra metre a worker or forklift has to travel is a direct cost to your operation. A well-designed layout creates a logical, seamless path from receiving goods to their final dispatch, cutting down on wasted movement and boosting productivity.

Core Warehouse Flow Strategies

Most efficient warehouse layouts are built around one of three fundamental flow patterns. The right choice hinges on your building's shape, the location of your docking doors, and your specific operational needs.

-

U-Shaped Flow: This is the most common and often the most efficient design. Goods enter and exit through doors on the same side of the building. Receiving and shipping areas are right next to each other, creating a circular, U-shaped path for inventory as it moves through storage and picking. This layout maximises space and encourages staff and equipment to be used across different tasks.

-

I-Shaped (or Through-Flow): Perfect for long, narrow buildings, this layout places receiving docks at one end and shipping docks at the opposite end. Inventory flows in a straight line right through the facility. While it keeps receiving and shipping activities separate and reduces congestion, it might require more staff and equipment.

-

L-Shaped Flow: This is a less common but practical solution for buildings with an L-shaped footprint. Receiving and shipping docks sit on adjacent walls, creating a workflow that moves around a corner. It can be very effective but needs careful planning to avoid bottlenecks at the turn.

This diagram shows some of the key hardware components you’ll need to arrange within these layouts.

As you can see, different racking systems—from versatile selective racks to specialised cantilever solutions—form the building blocks of any efficient layout.

The Art of Strategic Slotting

Once you’ve settled on a flow pattern, the next step is slotting. This is the crucial process of strategically assigning specific locations for each product based on how often it’s picked. Think of it like a supermarket manager placing everyday essentials like milk and bread at the back of the store to guide customer traffic past other items.

In a warehouse, you do the opposite: you place your fastest-moving products in the most accessible locations to minimise picker travel time. Slow-moving items can be tucked away in less convenient, higher, or more distant spots.

Effective slotting is all about data. By analysing sales velocity, you can create a 'heat map' of your inventory and position items for maximum efficiency. To get the most out of your space, architects and designers also need a precise understanding of the physical dimensions of incoming goods. This often starts with a complete guide to 40ft container size and specs to plan receiving areas accurately.

Creating Dedicated Operational Zones

A high-efficiency layout is more than just storage aisles. It involves creating clearly defined zones for each stage of the operational process. This organised approach reduces chaos and ensures each task is performed in a purpose-built area, supported by the right equipment and people.

These dedicated zones are more important than ever as the UK warehousing workforce expands. The sector has seen enormous growth, with employment more than tripling from 81,000 in 2010 to around 284,000 by 2023. With this boom in human resources for tasks like receiving and order picking, zoned and efficient layouts are critical.

Ultimately, the right layout streamlines every single function, from unloading lorries to loading them up again. For developers, mastering these design principles is key. You can explore our expert insights on how to design a self-storage facility for maximum efficiency to delve deeper into optimising space for profitability.

Executing Your Project from Plan to Handover

Getting from a detailed blueprint to a fully operational warehouse is a journey with several make-or-break stages. A successful project isn't just about the design; it's about expertly navigating compliance, managing the installation, and handling the final handover. Think of this as your roadmap, breaking down the entire process into clear, manageable steps.

This is the phase where your investment starts to take physical shape. Get it right, and your warehouse storage solutions will be efficient, safe, compliant, and delivered on time. Skip a step, and you could be looking at serious delays, surprise costs, and regulatory nightmares.

Navigating Initial Design and Consultation

The first real step is a thorough consultation. This is where you sit down with specialists and turn your operational goals into a tangible design. It’s a deep dive into what you actually need, looking at everything from storage density and inventory flow to the specific types of goods you’ll be handling.

This collaborative process is your best defence against costly mistakes down the line. A solid initial design becomes the project's North Star, ensuring every decision that follows aligns with your core objectives. It confirms the systems you've chosen aren't just good on paper but are genuinely right for your building and your business.

A well-executed project is built on the bedrock of meticulous planning. Rushing the initial consultation is like building a house without checking the foundations—sooner or later, the cracks will start to show. This upfront diligence is the single best investment you can make.

With a concrete plan in place, you can move on to technical specifications and procurement with confidence.

Mastering UK Compliance and Regulations

Before a single bolt is tightened, your project has to navigate the complex web of UK compliance. Let's be clear: this is non-negotiable. Sticking to these standards is essential for a safe, legal, and insurable facility. Overlooking this stage can completely derail a project, leading to failed inspections and expensive rework.

Key areas you absolutely must get right include:

- Health and Safety: Every installation has to comply with regulations from the Health and Safety Executive (HSE). This focuses on everything from operator safety to structural integrity.

- Fire Regulations: Your layout and the materials you use must meet strict fire safety standards. This means ensuring clear escape routes and using fire-retardant components where required.

- Load Capacity and Signage: Every single racking system must have clear, visible signage showing its maximum load capacity. More importantly, the racks must be professionally certified to handle those specified weights safely.

Working with experts who live and breathe these regulations is crucial. They’ll ensure your design is compliant from the get-go, saving you from major headaches when it’s time for final inspections.

Managing Installation and Final Handover

The final stage is the physical installation and commissioning of your new storage systems. This part of the process demands precise coordination, skilled installers, and rigorous project management to keep everything on track. Choosing a qualified and experienced installation partner is paramount here.

The installation should be managed against a clear timeline with key milestones. Regular progress checks and open communication with your installation team are the best ways to tackle any potential delays head-on. Once the build is complete, the project moves into the handover phase. For a deeper look into managing these final stages, our guide on storage facility project management provides a detailed overview.

This final step involves a top-to-bottom inspection of the finished work. You should conduct a thorough walkthrough to check that every component has been installed exactly as specified and meets all safety standards. Only after a successful final inspection and official sign-off is the project truly complete and ready to go.

Tapping Into the Profitable Self-Storage Market

Beyond the world of traditional industrial warehousing, there's a dynamic and incredibly profitable niche just waiting for UK developers: the self-storage market. It’s a different beast entirely, but it offers a compelling investment opportunity driven by powerful social and economic shifts. Think of it as a major segment of the broader demand for warehouse storage, but with its own unique flavour.

So, what's fuelling all this growth? It comes down to a few key trends. For starters, our urban living spaces are getting smaller, pushing people to find somewhere else to keep their personal belongings. At the same time, the boom in small e-commerce businesses has created a massive need for flexible, scalable inventory space that a stuffy, long-term warehouse lease just can't provide.

This unique customer base means the physical setup is miles away from your typical logistics hub. To succeed here, you need specialised infrastructure.

Unique Solutions for a Unique Market

Self-storage facilities aren't just empty warehouses with a new sign. They are purpose-built environments designed from the ground up for public access and top-notch security. The core components look nothing like what you’d find in a building designed for palletised goods; instead, the focus is all on individual, secure units.

Key infrastructure includes:

- Partitioned Steel Units: These are the backbone of any facility. They create the individual lockers and rooms of various sizes that cater to a wide range of customer needs.

- Container Storage: Offering external, drive-up container units gives customers a robust, convenient option for storing bulkier items like furniture or even vehicles.

- Robust Security Systems: High-definition CCTV, individually alarmed units, and controlled gate access aren't just nice-to-haves. They're fundamental for building the trust that keeps customers coming back.

- Access Control Technology: Modern facilities are ditching old-school keys for automated systems like keypads or mobile apps. This provides customers with secure, 24/7 access, which is a huge selling point.

This customer-facing model puts a much bigger emphasis on technology and user experience, setting it worlds apart from business-to-business warehousing.

The self-storage operational model is leaner and more automated than traditional warehousing. With lower daily staffing needs and a focus on customer-facing tech for rentals and access, it offers a distinct path to generating strong, consistent rental returns.

To really get the most out of day-to-day operations and maximise returns, checking out the best property management apps can give you a significant edge.

A Compelling UK Investment

The UK self-storage market just keeps showing remarkable resilience and growth, making it an incredibly attractive prospect for developers. The sector is defined by high demand and healthy rental yields, all propped up by a steadily growing customer base.

Recent industry data paints a very clear picture of this strength. As of 2024, the UK is home to over 2,900 self-storage sites. Together, they offer a combined 64.3 million square feet of space—that's a 7.2% increase from the previous year. Even with a slight dip in occupancy, the sector’s annual turnover shot past £1.2 billion, with average rental returns climbing by 6% to £29.13 per square foot. These aren't just numbers; they highlight a robust and expanding market. You can dive into the complete analysis in the UK Self Storage Annual Report from Cushman & Wakefield.

For developers, this data signals a clear opportunity. By getting to grips with the specific needs of this market—from partitioned units to advanced security—you can create highly profitable assets. For anyone seriously considering this venture, understanding the key steps is crucial. Our guide on seeing self-storage as a business offers some valuable insights into planning and launching a successful facility.

Turning Your Storage Investment Into Profit

So, you’ve got the blueprint. You’ve planned the layout, picked the systems, and navigated the regulations. Now for the most important part: turning all that hard work into a profitable asset.

This is where the rubber meets the road, connecting your technical decisions to real financial outcomes. After all, the big question for any developer is simple: how does this investment actually pay off? A smart storage solution isn't just an expense; it’s the engine that drives your return.

Before you can even start counting the profits, you need to get the project off the ground. That means securing the right funding without tying up all your capital reserves.

Understanding Your Financing Options

There are a few well-trodden paths for funding your warehouse or self-storage solutions, and each has its own set of pros and cons. The best choice really boils down to your business's current financial health and your long-term goals.

Here are the most common routes:

- Asset Finance: This is a popular one. You essentially borrow against the value of the equipment you’re buying, like the racking or a new mezzanine floor. The loan is secured by the assets themselves, which can make it easier to obtain.

- Commercial Loans: Think of this as the traditional bank loan. You get a lump sum to fund the project and pay it back over a set period. If you’ve got a solid business case, you can often lock in some competitive interest rates.

- Leasing: Instead of buying everything outright, you can lease the equipment for a fixed term. This keeps your initial spending low and often wraps maintenance costs into the deal. The catch? You won’t own the assets when the lease is up.

Each option impacts your cash flow, ownership, and flexibility differently. It pays to crunch the numbers on all of them to make sure your project starts on a solid financial footing.

Calculating Your Return on Investment

Once the funding is sorted, the focus shifts to proving the project's worth. This is where Return on Investment (ROI) comes in. It’s not just about making sure the numbers add up; it’s about showing exactly how much new value your optimised facility is creating.

ROI gives you the clear, data-backed evidence you need to justify the initial spend. It changes the conversation from "How much does it cost?" to "How much will it make us?" – a crucial shift for getting everyone on board.

The basic formula is straightforward enough: weigh the total cost against the net profit it generates. The real art, though, is in spotting and measuring all the gains accurately. These benefits go way beyond just the monthly rental income; they often include massive operational savings.

To build a truly compelling business case, you need to put a number on gains like:

- Increased Storage Density: A smarter layout equals more rentable square metres. It’s a direct and immediate boost to your revenue potential.

- Improved Picking Efficiency: Better workflows mean less time spent per order. Over a year, those saved labour costs really add up.

- Reduced Operational Errors: An organised system cuts down on mistakes, which means fewer costly returns or inventory write-offs.

When you can attach real figures to these benefits, you create an undeniable argument for the investment. It clearly shows how a strategic warehouse storage solution translates directly into long-term, sustainable profit.

Your Top Warehouse Storage Questions Answered

When you're in the thick of a warehouse development project, the same practical questions tend to pop up again and again. Getting straight answers can save you a world of time, money, and headaches down the line. It's about making sure your storage solutions are built on a solid foundation of smart choices.

Let's tackle some of the most common hurdles that developers and operators face, bridging that gap between high-level strategy and what actually happens on the ground.

Should I Go for New or Used Racking?

This is a classic dilemma, and it really comes down to balancing your initial budget against long-term reliability. Used racking can look incredibly tempting, sometimes offering savings of up to 40% compared to new. That's a figure that makes anyone on a tight budget sit up and take notice.

But stepping onto the used racking path means you need to have your eyes wide open. You're giving up the manufacturer's warranty and any real certainty about its history. You have no way of knowing if it's been overloaded, bashed by a forklift, or poorly repaired in a past life, all of which could seriously compromise its structural integrity.

Choosing used racking might slash your upfront costs, but it shifts all the responsibility for safety and compliance squarely onto your shoulders. You'll need to be ready to bring in a qualified engineer for a thorough structural assessment to make sure it's fit for purpose and meets current UK regulations.

New racking, on the other hand, is a clean slate. It arrives with a full warranty, a guarantee that it meets the latest safety standards, and complete peace of mind. Yes, the initial cheque you write will be bigger, but the long-term value you get from its durability and reduced risk is often an investment that pays for itself.

What Are the Key UK Safety Regulations I Need to Know?

In the UK, warehouse safety isn't just a good idea—it's the law. The Health and Safety Executive (HSE) enforces a strict set of regulations, and compliance is non-negotiable. For anyone developing a new facility, getting these rules right from day one is fundamental.

Here are three critical areas you absolutely have to get right:

- Regular Inspections: Your racking needs to be inspected regularly by someone who is technically competent. The gold standard is to have an annual inspection carried out by a SEMA (Storage Equipment Manufacturers' Association) Approved Racking Inspector.

- Visible Load Notices: Every single racking installation must have clear, easy-to-read load notices. These signs need to spell out the maximum safe working loads for both the beams and the entire bay to prevent dangerous overloading.

- Rack Protection: High-traffic areas demand solid rack protection. It’s mandatory to install things like column guards and end-of-aisle barriers to shield vulnerable racking uprights from forklift collisions—one of the biggest causes of racking failure.

How Can I Mix Technology with My Traditional Storage?

You don't need to rip everything out and start again with a multi-million-pound automated system to bring your warehouse into the 21st century. The smart move is to integrate modern tools with your traditional warehouse storage solutions to get a major efficiency boost without breaking the bank. Think enhancement, not a total replacement.

A Warehouse Management System (WMS) is the perfect place to start. This software essentially becomes the brain of your operation, helping you get a grip on inventory tracking, order picking, and making the best use of your space. Pair it with simple hardware like barcode scanners, and you’ll slash human error while gaining real-time visibility into your stock levels.

Even entry-level automation can make a huge difference. Something as simple as installing conveyors to move goods from your packing stations to the shipping zone can cut down on how much your team has to walk, speeding up dispatch times considerably.

Ready to design a self-storage facility that maximises your return on investment? The expert team at Partitioning Services Limited specialises in end-to-end project management, from initial design and compliance to manufacturing and installation. Explore our turnkey self-storage solutions at https://psllimited.co.uk.

Looking for help with your next project?

Whether you are new to self storage or already have an established self storage facility, we can provide you with guidance and a full quotation for any aspect of your works.