Installing a Mezzanine Floor A Developer's Guide

Installing a mezzanine floor is a project won in the planning phase, long before any steel arrives on site. A successful installation really comes down to a detailed needs analysis, a thorough structural check of your building, and smart design choices that maximise your return. Get these fundamentals right, and you're set up for a seamless, valuable expansion.

Your Blueprint for a Successful Mezzanine Installation

Before a single bolt is tightened, the success of your mezzanine project is determined by the quality of your blueprint. For self-storage developers and facility managers, this initial planning stage is non-negotiable. It’s where you translate day-to-day operational needs into a physical structure, heading off costly overhauls and ensuring the final build perfectly aligns with your business goals.

This isn't just about drawing up a quick sketch. It’s about diving deep into the technical and practical details that define a high-value installation.

The whole process kicks off with a comprehensive needs analysis. This is more than just adding square footage; it's about defining the purpose of that new space.

- Load Capacity Requirements: What's this floor actually holding? Will it support heavy pallets, light-duty storage units, or office space? A floor designed for archives (around 3.5 kilonewtons per square metre) has vastly different structural needs than one supporting heavy machinery or high-turnover goods (7.2 kN/m² or more).

- Layout and Workflow: Think about how staff and customers will get to the new level. The placement of staircases, pallet gates, and lifts must optimise flow, not create frustrating bottlenecks. An inefficient layout can completely wipe out the benefits of having the extra space.

- Future Flexibility: What does your five-year plan look like? Designing a mezzanine with a slightly higher load capacity or a more adaptable column grid can give you crucial flexibility for future changes without having to rip everything out and start again.

Assessing Your Building's Structural Integrity

Once you’ve figured out what you need, you have to confirm your building can actually support it. A mezzanine floor adds a significant load, and your existing structure—specifically the concrete floor slab—must be able to handle the point loads from the new columns.

A structural engineer will need to conduct a thorough site survey. This often includes core sampling your concrete slab to test its depth and compressive strength. Don't even think about skipping this. An inadequate slab can lead to catastrophic failure, making this assessment an absolutely non-negotiable part of your due diligence.

"Many facility managers underestimate the importance of the floor slab survey. The entire stability of the mezzanine rests on the foundation it’s bolted to. Assuming your existing floor is adequate without professional verification is the single biggest risk in the entire project."

Establishing a robust safety foundation from the very beginning is paramount. Using a practical guide to health and safety management systems can provide the comprehensive framework needed to keep your project on track and everyone safe.

Making Critical Design and Material Choices

With a clear picture of your needs and your building's capacity, you can get into the design specifics. The key decisions you make here will directly impact both your budget and the final functionality.

Column Grid Optimisation

The spacing of your support columns is a balancing act. Wider spans create more unobstructed, usable floor space below but require heavier, more expensive steel beams. A typical grid might be around 5m x 5m, but this should be tailored to your specific layout, like aligning columns with planned storage unit corridors to keep things neat and tidy.

This detailed plan shows the careful layout of columns and beams required for a stable mezzanine structure.

As you can see, every component, from the main beams down to the secondary joists, is meticulously mapped out. This is what ensures total structural integrity and makes the most of the space you have.

Decking Material Selection

The surface of your mezzanine floor is another crucial choice with a couple of main options:

- 38mm Particle Board: This is the most common and cost-effective choice, perfectly suitable for standard storage and light foot traffic.

- Composite Decking: If you need something more robust, a steel deck with a concrete screed top offers superior durability, fire resistance, and sound insulation. It's the ideal choice for office spaces or heavy-duty applications.

The demand for these kinds of installations has exploded. According to the Office for National Statistics (ONS), the number of UK business premises for storage and transport shot up by a staggering 88% between 2010 and 2020. This boom is fuelling the need for space-maximising solutions like mezzanines more than ever before.

Navigating UK Building Regulations and Compliance

Getting to grips with UK Building Regulations isn't just a box-ticking exercise when you're installing a mezzanine floor—it's the absolute foundation of a safe, legal, and insurable project. For self-storage developers, pushing compliance down the to-do list is a surefire way to hit costly delays, forced redesigns, and even serious legal trouble. This isn't just about paperwork; it's about the structural integrity of your facility and the safety of everyone inside it.

You can pretty much guarantee that any mezzanine floor installation will need a formal Building Regulations application. The second you add a new level into your building, a whole host of legal requirements kick in, and they have to be handled professionally. This is all managed through your local authority’s building control department or a private approved inspector.

Key Regulations You Cannot Ignore

The rulebook is thick, but for mezzanines, three specific Approved Documents are the ones you really need to focus on. These documents give you the practical guidance for meeting the legal standards.

- Approved Document A (Structure): This is all about the structural safety of the mezzanine itself. It demands detailed calculations from a qualified structural engineer to prove the steelwork can handle its intended loads. Crucially, it also verifies that the building’s existing foundation—especially the concrete slab—can support the new point loads from the columns.

- Approved Document B (Fire Safety): This is, without a doubt, the most critical and complex part of compliance. It sets the rules for everything from escape routes and the fire resistance of the structure to smoke detection systems.

- Approved Document M (Access and Use): This document ensures the new level is accessible. While a full lift isn’t always required for a storage mezzanine, the design of your staircases—their width, pitch, and handrail setup—all fall under its remit.

For any major construction project, it's also vital to be up to speed with legislation like the Building Safety Act 2022, which has put a much bigger focus on competence and accountability across the industry.

A classic mistake is assuming a mezzanine is a 'temporary' structure and therefore exempt. In the eyes of UK law, if people are using it and it’s fixed in place, it must comply. That one misunderstanding could land you with an enforcement notice from the council demanding you tear the whole thing down.

This regulatory landscape can feel like a minefield. To get a better handle on what’s involved, our detailed guide offers more specifics on UK building regulations for mezzanines.

Fire Safety: The Non-Negotiable Element

Fire safety compliance will shape a huge part of your mezzanine’s design—and its cost. The rules are driven primarily by the size of the floor and how it will be used.

One of the very first things your designer will calculate is travel distances. The path from any point on the mezzanine to the nearest protected escape route (like a fire-rated staircase) has to be within strict limits. Typically, that’s around 25 metres if there's only one way out, or 45 metres if there are multiple escape routes. If your floor plan exceeds these distances, you'll have no choice but to add more staircases.

Fire protection for the structure itself is the other piece of the puzzle.

- When is Fire Protection Needed? As a rule of thumb, if the mezzanine’s area is over 400 square metres, or if it takes up more than 50% of the room it’s in, the underside will need fire protection. It’s also often a requirement if people will be permanently working on or below the structure.

- What Does It Involve? This usually means wrapping the steel columns and beams in fire-rated materials, like a suspended ceiling or special intumescent paint. The goal is to achieve 60 minutes of fire resistance, which buys precious time for people to evacuate safely before the structure’s integrity is compromised.

Your application to building control needs to be watertight, complete with detailed architectural drawings, structural calculations, and a clear fire safety plan. An experienced mezzanine provider will manage this whole process for you, dealing directly with inspectors to make sure everything goes through smoothly. Nailing this from the very beginning is the key to a successful and fully compliant installation.

The On-Site Mezzanine Installation Process

Once the detailed plans are signed off and the steelwork is fabricated, your mezzanine project moves from paper to the physical world. This is where the real action happens—a carefully choreographed sequence on-site where precision, safety, and efficiency are everything. For facility managers, knowing what to expect helps manage the day-to-day and lets you coordinate with the installation team to keep any disruption to a minimum.

But the process doesn't just start when the lorries pull up. The groundwork for a smooth installation is laid long before that, starting with getting the site absolutely ready. Get this right, and the team can hit the ground running without a single delay.

Preparing the Site for Installation

A clean, clear site is the bedrock of a successful build. The entire installation footprint needs to be completely free of stock, machinery, and personnel. This isn't just about making room; it's a critical safety step to establish a secure work zone.

Our installation team will run final checks on the concrete slab, making sure it’s ready for the column baseplates. Any last-minute cleaning or minor remedial work should be done and dusted by this point. It’s also vital that access routes for delivery vehicles and lifting equipment are confirmed and kept clear.

A classic oversight we see is forgetting about what’s overhead. Before the team arrives, do a final sweep for any low-hanging light fixtures, trunking, or heating units inside the installation zone. Catching these early saves a world of headaches and costly delays when the steel columns are being lifted into position.

Component Delivery and Organisation

The day the materials arrive is a major milestone. All the mezzanine components—columns, main beams, secondary joists, decking, and fixings—are delivered on large flatbed lorries. An experienced crew coordinates this delivery to match the build sequence perfectly, so materials are offloaded and organised in a logical flow.

This strategic placement is what separates a slick operation from a chaotic one.

- Columns and Baseplates: These are usually the first things off the lorry, positioned around the installation area close to where they will be erected.

- Main Beams (Primary Beams): As the biggest and heaviest components, these are placed where lifting equipment can get to them easily.

- Secondary Joists and Decking: These are stacked neatly to one side, ready to be brought in once the main frame is up and secure.

Getting the material handling right at this stage speeds up the entire assembly process, cutting down the time everyone spends moving heavy components around the site.

The infographic below shows the core regulatory pillars that shape the entire installation, from the steel framework right through to fire safety and final access.

This visual really drives home how structural integrity, fire protection, and accessibility are all linked, guiding every single step of the on-site build to ensure you're fully compliant.

The Core Assembly Sequence

With the site prepped and materials laid out, the physical construction can kick off. This is where the skill of the installation team really comes to the fore, as they turn a collection of steel parts into a solid, robust structure.

It all starts with meticulously marking out the column positions on the floor, cross-referencing against the approved design drawings. Once every position is confirmed, the columns are raised vertically, set on their baseplates, and anchored to the concrete slab with heavy-duty bolts.

Next up, the main support beams are lifted into place and bolted to the column heads, creating the primary skeleton of the mezzanine. The team uses precision levelling tools to make sure the frame is perfectly square and level before tightening every connection to the specified torque. It has to be spot on.

Once that primary frame is established, the secondary joists are installed, running perpendicular to the main beams. These are bolted into place, creating a dense grid that will support the decking. This phase is done methodically, bay by bay, until the entire steel structure is assembled.

Finally, the decking panels—typically 38mm high-density particle board—are laid across the joists. The tongue-and-groove design creates a tight, secure fit, and the panels are screwed down to form a solid, stable floor surface ready for action.

Installing Staircases and Edge Protection

The last stage of the main construction is all about access and safety. This part is non-negotiable, ensuring the new level is safe and compliant from the moment we hand it over.

Staircases and any landings are assembled and fixed securely to both the main structure and the ground floor. The positioning and angle must match the design drawings to the millimetre to comply with Building Regulations Part M (Access and Use). For more dynamic environments, there are some really versatile options out there; you can learn more about rolling staircases that offer smooth and safe access in our dedicated guide.

At the same time, edge protection is installed around all exposed perimeters of the mezzanine. This involves fitting a robust handrail and kick plate system to prevent falls and stop items from being accidentally knocked off the edge. Any specified pallet gates are also fitted at this stage, providing a safe way to load goods onto the new level.

Throughout this entire on-site process, a proficient installation team will work to minimise disruption, using safety barriers and clear signage to segregate the work area, allowing your facility to remain operational where possible.

Budgeting Your Project and Calculating ROI

Let’s talk numbers. A successful mezzanine project lives and dies by its financials. It’s not just about the engineering or getting the paperwork signed off; the investment has to make solid business sense. Figuring out the costs and, just as importantly, how to calculate the return on that investment is what separates a good idea from a profitable reality for your self-storage facility.

Trying to pin down a budget for a mezzanine floor isn't like picking an item off a shelf. The final figure is a mix of several key variables, and each one plays a part in the total cost. Getting a grip on these factors early means you can build a realistic financial plan and dodge any nasty surprises later on.

Breaking Down the Key Cost Drivers

The price of a mezzanine isn't a one-size-fits-all number. A few crucial elements directly shape your quote, and knowing what they are helps you see exactly where your money is going.

- Size and Area: This one’s straightforward. The total square meterage is the biggest factor. A larger floor naturally needs more steel, more decking, and more labour, which all adds up.

- Load Rating: What are you putting on it? This is a massive cost driver. A mezzanine designed for lighter storage or a small office (around 4.8 kN/m²) will use lighter-gauge steel. But if it needs to support heavy-duty storage units (7.2 kN/m² or higher), the structure has to be much more robust—and therefore, more expensive.

- Design Complexity: A simple, square mezzanine with a standard column grid will always be the most cost-effective option. If you need a complex, multi-level design with funny shapes or wide, non-standard spans, it will require heavier, pricier beams to make it work.

- Decking Material: Your choice of flooring directly impacts the budget. The industry standard for most storage applications is 38mm particle board, which gets the job done well. However, if you need something tougher or with better fire resistance, like a composite concrete deck, expect the material and installation costs to climb.

Estimated Costs for Mezzanine Floor Installation in the UK

To give you a clearer picture, here’s a rough guide to what you might expect to pay for the decking, which is a major part of the overall cost. Remember, these are ballpark figures and don't include extras like fire protection, staircases, or specialist lifting gear.

| Decking Type | Typical Cost per m² (GBP) | Best Suited For |

|---|---|---|

| 38mm Particle Board | £100 - £150 | General self-storage units, light office use, standard load-bearing |

| Composite Concrete | £200 - £300 | Heavy-duty storage, high-traffic areas, enhanced fire resistance |

| Steel Chequer Plate | £180 - £250 | Industrial applications, workshops, areas with potential for liquid spills |

These figures show just how much the decking choice can influence your budget. For most self-storage operators, the standard particle board offers the best balance of performance and cost.

Calculating Your Return on Investment

For a self-storage business, calculating the ROI on a mezzanine is refreshingly direct. You’re not trying to measure abstract gains in efficiency; you’re adding new, rentable space that generates predictable monthly income. This clarity makes it much easier to build a powerful business case for the expansion.

First, you need to work out the total project cost. This isn’t just the mezzanine itself. Be sure to include all the associated expenses, like fire protection, lighting, and the partitioning you’ll need to create the new storage units.

Once you have your all-in investment figure, you can project the new revenue stream. It breaks down like this:

- Work out the new unit count: Based on your new floor plan, calculate exactly how many new storage units you can fit on the mezzanine level.

- Estimate your monthly rental income: Using your current rental rates for similar-sized units, figure out the total extra monthly revenue the new units will bring in.

- Project the annual revenue: Multiply that additional monthly income by 12. That’s your projected annual revenue boost.

By translating new square footage directly into rentable units, you turn a construction cost into a tangible, income-generating asset. The question quickly changes from ‘How much will it cost?’ to ‘How quickly will it pay for itself and start generating pure profit?’

With these figures in hand, calculating a clear payback period is simple. For example, if your total project cost is £150,000 and the new level generates an additional £5,000 in rental income per month (£60,000 per year), your payback period is just two and a half years. After that, every penny of that revenue stream goes straight to your bottom line. It’s a compelling argument for making the investment.

For a deeper dive into the types of floors available and their benefits, our guide to commercial mezzanine floors is a great place to start.

Final Checks, Commissioning and Handover

The final bolt has been tightened and the installation team is packing up, but the job isn't quite done yet. This last stage—commissioning and handover—is where you officially sign off on the project. It’s a critical step that transforms the structure from a building site into a fully operational, compliant, and safe part of your facility. Don't rush this part; it's your last chance to catch any issues before they become long-term headaches.

A thorough handover is your guarantee that the work meets the standards you agreed upon and that you have everything needed for ongoing management. Think of it as your final opportunity to have the contractor fix anything before you officially take ownership.

The Final Walkthrough and Snagging List

Before you even think about signing any completion forms, you need to do a detailed final walkthrough with your contractor’s project manager. This is your chance to get up close and inspect every single aspect of the installation. Be meticulous. Don't be afraid to point out even the smallest imperfections.

Here's what you should be looking for:

- Structural Integrity: Check all the bolted connections. Are the surfaces perfectly level? Give the staircases and handrails a good shake—there should be absolutely no movement or wobble.

- Surface Finishes: Scan the decking for any damage, scratches, or panels that don't sit flush. Check the paint finish on the steelwork to make sure it's consistent and complete.

- Safety Features: Confirm all edge protection, like handrails and kick plates, is securely fitted. If you have pallet gates, test them to make sure they operate smoothly and safely.

- General Tidiness: The site should be left clean and completely free of any construction debris. It sounds obvious, but you'd be surprised.

As you walk the site, create a "snagging list" documenting anything that needs to be put right. This could be anything from minor cosmetic touch-ups to more significant adjustments. A professional contractor will expect this and will work through your list until you are 100% satisfied.

Essential Documentation Handover

Getting the right paperwork is just as important as the physical build itself. These documents are your proof of compliance, and they’re essential for insurance, any future building work, and even the potential sale of the property. Without them, you're opening yourself up to serious legal and operational problems.

A common and costly oversight is accepting a mezzanine without the final Building Regulations completion certificate. This single document is your legal proof that the structure is compliant. Without it, your entire installation is technically not signed off by the local authority.

Your handover pack absolutely must include:

- Building Regulations Completion Certificate: This is the official document from the building control body, confirming the installation meets all legal standards. It's non-negotiable.

- Structural Calculations: The complete engineering report detailing load capacities and the structural design. You'll need this for your records.

- Operation and Maintenance (O&M) Manual: This gives you clear guidance on how to look after your mezzanine, including inspection schedules and maintenance tips.

Preparing Your Operations

Finally, before you open the new level for business, it's time for an internal readiness review. This is all about preparing your team and facility for the new layout.

Make sure load capacity signs are prominently displayed, both at the base of the stairs and near any loading points. Brief your staff on the new workflow, safety protocols, and, most importantly, the weight limits of the floor.

This careful prep work bridges the gap between construction and day-to-day operation. The global mezzanine floor market was valued at approximately $15.85 billion in 2024, and it's easy to see why. As businesses look to maximise their vertical space, demand is only growing. You can discover more insights about the mezzanine market on TechSci Research. A successful handover ensures your investment is ready to deliver value from day one.

Common Questions About Mezzanine Installations

Even with a rock-solid plan, you’re bound to have questions when it comes to installing a new mezzanine floor. Getting clear, straight answers demystifies the process and helps you move forward with confidence. We’ve pulled together the most common questions we hear from developers and facility managers to give you the practical insights you need.

How Long Does a Typical Mezzanine Installation Take?

It’s a common misconception that the on-site build is the longest part of the project. In reality, the physical installation is often surprisingly quick. An experienced team can usually get a standard 5,000 sq ft mezzanine assembled on-site in just 5-10 working days.

The real timeline, however, is shaped by the crucial prep work that happens beforehand. From the moment you place an order to the final handover, the entire project typically takes between 8 to 12 weeks. This window covers everything from detailed design work and structural calculations to fabricating the steelwork and securing Building Regulations approval.

The key takeaway? Factor in the full project lifecycle, not just the construction phase. Engaging with your provider early helps create a realistic timeline that aligns with your operational goals and prevents nasty surprises down the road.

Do I Always Need Planning Permission?

This one causes a lot of confusion, but the answer is usually quite simple. In most cases, you do not need planning permission for a mezzanine floor. Because they’re considered demountable, independent structures that don’t change the building’s external appearance, they typically fall outside the scope of planning consent.

What you almost certainly will need, though, is Building Regulations approval. This is a completely separate and non-negotiable process that ensures the structure is safe, sound, and compliant with fire safety standards. Never mistake the lack of a need for planning permission as a free pass—Building Regulations are mandatory. Always double-check the specifics with your local authority before starting any work.

Can a Mezzanine Be Installed in an Active Facility?

For a busy self-storage facility, shutting down operations for weeks on end just isn't an option. The good news is that professional installation teams are well-versed in working within live, active environments. The whole process is designed to cause minimal disruption from start to finish.

Installers use several smart strategies to keep your business running smoothly:

- Phased Work Schedules: Work can often be scheduled during your quieter periods, including nights or weekends, to avoid interrupting peak hours.

- Secure Work Zones: The installation area is safely cordoned off with barriers and clear signage to protect your staff and customers.

- Efficient Logistics: All materials are delivered and organised to streamline the build, reducing the amount of time equipment and components are moved around your site.

What Is the Minimum Ceiling Height Required?

Getting the headroom right is critical for both safety and legal compliance. As a general rule of thumb, you need a minimum clear ceiling height of around 4.5 to 5 metres to comfortably fit a mezzanine.

This measurement is vital because it allows for the required 2 metres of clear headroom both above and below the mezzanine deck. This isn't just a friendly suggestion; it's a key requirement under UK Building Regulations. Anything less creates an unsafe environment and simply won't get signed off by a building control inspector, which is why accurate site measurement is one of the very first and most important steps.

At Partitioning Services Limited, we manage every aspect of your mezzanine floor installation, from initial design and regulatory compliance to final handover, ensuring your project is delivered on time and on budget. Start your project with us today.

Warehouse Storage Solutions A Developer's Guide

Warehouse storage solutions are the systems you use to organise your stock—everything from simple shelving to complex automated racking—to make your operation as efficient, safe, and profitable as possible. Think of them as more than just static racks; they're the very backbone of your facility, dictating how quickly you can get goods in, stored, and shipped back out.

Understanding Warehouse Storage as a Strategic Asset

It wasn’t long ago that a warehouse was seen as just a cost centre—a big, static box for holding goods. That thinking is now completely outdated. The seismic shift in consumer behaviour and the explosion of e-commerce have turned warehousing into the dynamic engine of the modern supply chain. For developers and operators, getting your head around this shift is non-negotiable.

A well-designed storage system isn't just a passive piece of the puzzle anymore; it's an active driver of your bottom line. Your choice of racking, the layout of your aisles, and the way your inventory flows have a direct impact on:

- Operational Efficiency: Slashing the time it takes for your team to find, pick, and pack orders.

- Space Utilisation: Squeezing the absolute maximum storage capacity out of your building's footprint.

- Profitability: Driving down labour costs, minimising product damage, and speeding up order fulfilment.

This strategic importance is why the sector is booming. The UK warehousing industry has grown massively, fuelled by the relentless rise of online retail. This growth just underscores the increasing demand for smarter, more efficient warehouse storage solutions. You can dig into the full research on the UK warehousing market growth at Ibisworld.

The Evolution from Storage to Fulfilment

The fundamental job of a warehouse has changed. It's no longer just about stacking pallets; it’s about fulfilling customer orders with lightning speed and pinpoint accuracy. This new reality demands a much more sophisticated approach to how we design these facilities.

A classic mistake is treating storage as an afterthought. An intelligent storage solution is the foundational framework that every other warehouse operation is built on. Get it right, and you create a high-performance asset. Get it wrong, and you build inefficiency right into your business model from day one.

The image below gives you a sense of a typical modern warehouse, where the racking systems and material handling equipment work together to create a seamless workflow.

What this really shows is that the physical infrastructure—the racks, the aisles, the equipment—sets the entire operational rhythm of the facility. That’s why choosing the right systems from the very beginning isn't just a logistical decision. It's a critical business strategy that will define your facility's potential for years to come.

Choosing the Right Tools for the Job

Picking the right warehouse storage solution is a lot like a skilled tradesperson choosing tools from their toolbox. You wouldn't use a sledgehammer to hang a picture, and you definitely wouldn't use the wrong racking system for a specialised inventory. Each system is engineered for a specific task, and getting to grips with their unique strengths is the first step towards designing a truly efficient facility.

We're going to move beyond simple specifications and look at the real-world application of these essential systems. This isn't just about what they are, but what they do for your operation. Nail this choice from the outset, and you'll prevent costly redesigns and operational headaches down the line, which has a direct impact on your profitability.

The All-Purpose Workhorse: Selective Pallet Racking

Think of selective pallet racking as the adjustable spanner of the warehouse world. It’s the most common and versatile system out there, and for good reason. Its simple design gives you direct, individual access to every single pallet. This makes it perfect for operations with a high number of different product lines (or SKUs) where getting to things quickly is the name of the game.

This system is all about accessibility, not density. While it won't win any awards for being the most space-efficient option, its flexibility is second to none. You can easily adjust beam levels to handle changing pallet heights, and it works seamlessly with any standard forklift. For a developer, this system is a low-cost, adaptable foundation that suits a wide range of potential tenants with varied stock needs.

High-Density Solutions for Maximum Capacity

When your main goal is to cram as much storage as possible into a given footprint, high-density systems are the specialised tools you need. They pull this off by cutting down the number of access aisles, effectively trading individual pallet access for a massive boost in capacity.

Drive-In and Drive-Through Racking are classic examples. Imagine packing a suitcase for a long trip—you arrange everything tightly to use every last bit of space. Drive-in racking does the same with pallets. Forklifts drive straight into the racking structure to place or retrieve pallets, which sit on rails. This "last-in, first-out" (LIFO) setup is ideal for storing large quantities of identical, non-perishable goods.

- Drive-In Racking: Has a single entry and exit point, making it a strict LIFO system.

- Drive-Through Racking: Allows access from both ends, which enables a "first-in, first-out" (FIFO) workflow. This is crucial for goods with an expiry date.

These systems can ramp up your storage capacity by up to 85% compared to standard selective racking. That makes them a powerful choice for cold storage or bulk goods warehousing where every square metre counts.

Specialised Systems for Unique Challenges

Of course, not all inventory fits neatly onto a standard pallet. For long, bulky, or awkwardly shaped items like timber, piping, or furniture, you need a purpose-built solution. That's where cantilever racking comes in. It uses a central column with arms extending outwards to support loads, getting rid of the vertical posts that get in the way with traditional pallet racking.

This design gives you clear, horizontal access, making it dead simple to store and retrieve cumbersome items. It’s a perfect example of how a specialised tool can solve a common warehouse headache, preventing product damage and making handling much safer.

Choosing a storage system isn't just about fitting more in; it's about creating a smarter workflow. The right system reduces travel time for pickers, minimises handling, and protects the value of the inventory it holds.

Another powerful, specialised solution is mezzanine flooring. This is less a racking system and more of a structural upgrade. By installing a second or even third floor within the existing vertical space of your warehouse, you can effectively double or triple your usable square meterage. This new area can be used for extra storage, office space, or light assembly work, offering incredible ROI without the expense of extending the building's footprint.

To help you weigh the core options for your next project, here’s a quick comparison.

Comparing Core Warehouse Storage Systems

This table offers a quick-reference guide to the most common storage systems, breaking down what they’re best for, their density, how accessible your stock will be, and the relative cost.

| System Type | Best For | Storage Density | Stock Accessibility | Relative Cost |

|---|---|---|---|---|

| Selective Racking | High SKU counts & fast turnover | Low-Medium | High (100% access) | Low |

| Drive-In Racking | Bulk storage of uniform products | Very High | Low (LIFO) | Medium |

| Cantilever Racking | Long, bulky, or irregular items | Medium | High (for specific items) | Medium-High |

| Mezzanine Flooring | Maximising vertical space | N/A | High | High |

Each system has its place. The key is matching the tool to the specific operational challenges you or your future tenants will face. Getting this right is fundamental to a successful and profitable warehouse development.

Designing a High-Efficiency Warehouse Layout

Having the right racking systems is only half the battle; how you arrange them on the floor dictates the operational rhythm of your entire facility. A smart layout transforms a simple collection of racks into a high-performance logistics hub, optimising the flow of goods, people, and machinery. It’s the difference between a chaotic workspace and a finely tuned engine for profit.

The goal is simple: minimise travel time. Every extra metre a worker or forklift has to travel is a direct cost to your operation. A well-designed layout creates a logical, seamless path from receiving goods to their final dispatch, cutting down on wasted movement and boosting productivity.

Core Warehouse Flow Strategies

Most efficient warehouse layouts are built around one of three fundamental flow patterns. The right choice hinges on your building's shape, the location of your docking doors, and your specific operational needs.

- U-Shaped Flow: This is the most common and often the most efficient design. Goods enter and exit through doors on the same side of the building. Receiving and shipping areas are right next to each other, creating a circular, U-shaped path for inventory as it moves through storage and picking. This layout maximises space and encourages staff and equipment to be used across different tasks.

- I-Shaped (or Through-Flow): Perfect for long, narrow buildings, this layout places receiving docks at one end and shipping docks at the opposite end. Inventory flows in a straight line right through the facility. While it keeps receiving and shipping activities separate and reduces congestion, it might require more staff and equipment.

- L-Shaped Flow: This is a less common but practical solution for buildings with an L-shaped footprint. Receiving and shipping docks sit on adjacent walls, creating a workflow that moves around a corner. It can be very effective but needs careful planning to avoid bottlenecks at the turn.

This diagram shows some of the key hardware components you’ll need to arrange within these layouts.

As you can see, different racking systems—from versatile selective racks to specialised cantilever solutions—form the building blocks of any efficient layout.

The Art of Strategic Slotting

Once you’ve settled on a flow pattern, the next step is slotting. This is the crucial process of strategically assigning specific locations for each product based on how often it’s picked. Think of it like a supermarket manager placing everyday essentials like milk and bread at the back of the store to guide customer traffic past other items.

In a warehouse, you do the opposite: you place your fastest-moving products in the most accessible locations to minimise picker travel time. Slow-moving items can be tucked away in less convenient, higher, or more distant spots.

Effective slotting is all about data. By analysing sales velocity, you can create a 'heat map' of your inventory and position items for maximum efficiency. To get the most out of your space, architects and designers also need a precise understanding of the physical dimensions of incoming goods. This often starts with a complete guide to 40ft container size and specs to plan receiving areas accurately.

Creating Dedicated Operational Zones

A high-efficiency layout is more than just storage aisles. It involves creating clearly defined zones for each stage of the operational process. This organised approach reduces chaos and ensures each task is performed in a purpose-built area, supported by the right equipment and people.

These dedicated zones are more important than ever as the UK warehousing workforce expands. The sector has seen enormous growth, with employment more than tripling from 81,000 in 2010 to around 284,000 by 2023. With this boom in human resources for tasks like receiving and order picking, zoned and efficient layouts are critical.

Ultimately, the right layout streamlines every single function, from unloading lorries to loading them up again. For developers, mastering these design principles is key. You can explore our expert insights on how to design a self-storage facility for maximum efficiency to delve deeper into optimising space for profitability.

Executing Your Project from Plan to Handover

Getting from a detailed blueprint to a fully operational warehouse is a journey with several make-or-break stages. A successful project isn't just about the design; it's about expertly navigating compliance, managing the installation, and handling the final handover. Think of this as your roadmap, breaking down the entire process into clear, manageable steps.

This is the phase where your investment starts to take physical shape. Get it right, and your warehouse storage solutions will be efficient, safe, compliant, and delivered on time. Skip a step, and you could be looking at serious delays, surprise costs, and regulatory nightmares.

Navigating Initial Design and Consultation

The first real step is a thorough consultation. This is where you sit down with specialists and turn your operational goals into a tangible design. It’s a deep dive into what you actually need, looking at everything from storage density and inventory flow to the specific types of goods you’ll be handling.

This collaborative process is your best defence against costly mistakes down the line. A solid initial design becomes the project's North Star, ensuring every decision that follows aligns with your core objectives. It confirms the systems you've chosen aren't just good on paper but are genuinely right for your building and your business.

A well-executed project is built on the bedrock of meticulous planning. Rushing the initial consultation is like building a house without checking the foundations—sooner or later, the cracks will start to show. This upfront diligence is the single best investment you can make.

With a concrete plan in place, you can move on to technical specifications and procurement with confidence.

Mastering UK Compliance and Regulations

Before a single bolt is tightened, your project has to navigate the complex web of UK compliance. Let's be clear: this is non-negotiable. Sticking to these standards is essential for a safe, legal, and insurable facility. Overlooking this stage can completely derail a project, leading to failed inspections and expensive rework.

Key areas you absolutely must get right include:

- Health and Safety: Every installation has to comply with regulations from the Health and Safety Executive (HSE). This focuses on everything from operator safety to structural integrity.

- Fire Regulations: Your layout and the materials you use must meet strict fire safety standards. This means ensuring clear escape routes and using fire-retardant components where required.

- Load Capacity and Signage: Every single racking system must have clear, visible signage showing its maximum load capacity. More importantly, the racks must be professionally certified to handle those specified weights safely.

Working with experts who live and breathe these regulations is crucial. They’ll ensure your design is compliant from the get-go, saving you from major headaches when it’s time for final inspections.

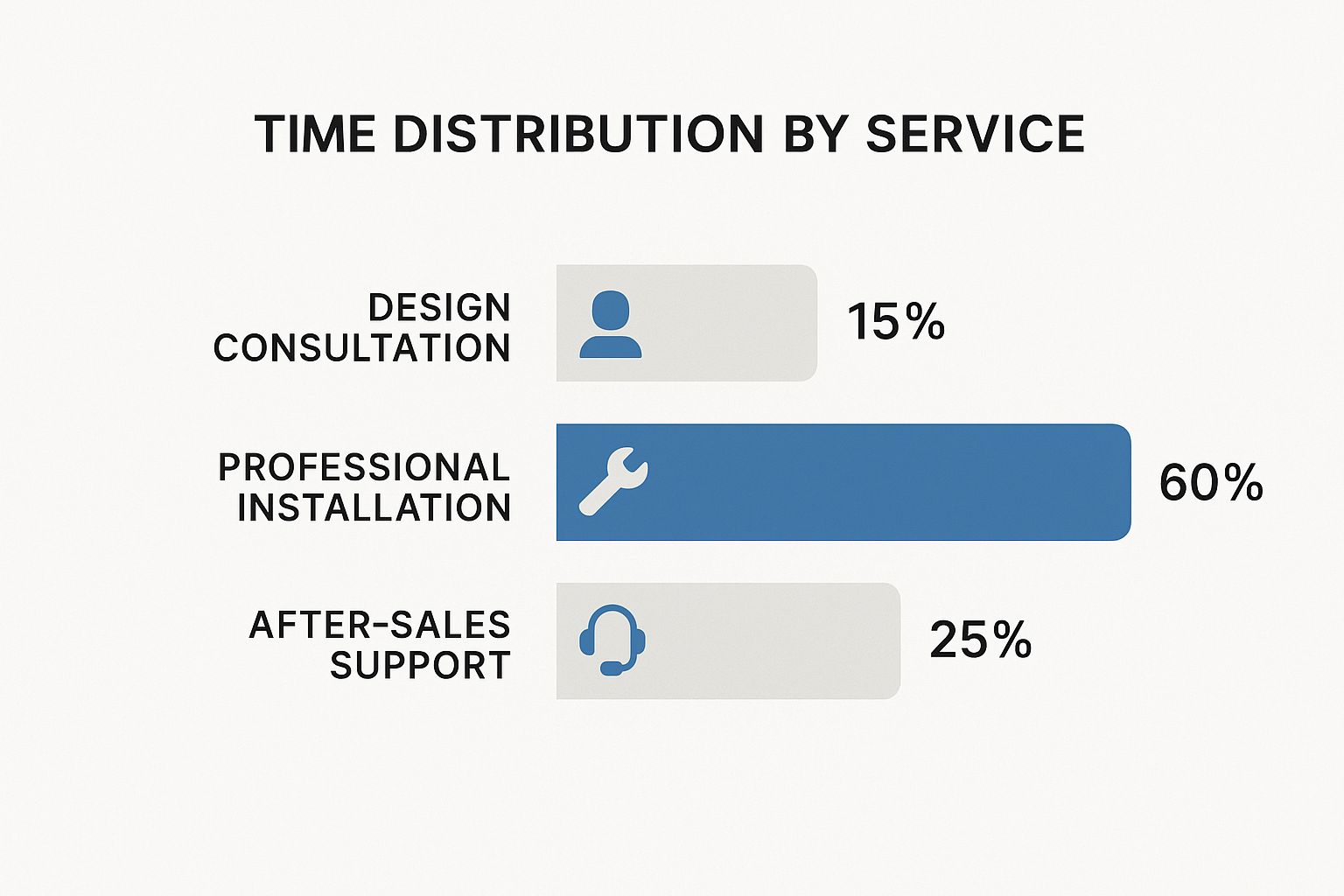

Managing Installation and Final Handover

The final stage is the physical installation and commissioning of your new storage systems. This part of the process demands precise coordination, skilled installers, and rigorous project management to keep everything on track. Choosing a qualified and experienced installation partner is paramount here.

The installation should be managed against a clear timeline with key milestones. Regular progress checks and open communication with your installation team are the best ways to tackle any potential delays head-on. Once the build is complete, the project moves into the handover phase. For a deeper look into managing these final stages, our guide on storage facility project management provides a detailed overview.

This final step involves a top-to-bottom inspection of the finished work. You should conduct a thorough walkthrough to check that every component has been installed exactly as specified and meets all safety standards. Only after a successful final inspection and official sign-off is the project truly complete and ready to go.

Tapping Into the Profitable Self-Storage Market

Beyond the world of traditional industrial warehousing, there's a dynamic and incredibly profitable niche just waiting for UK developers: the self-storage market. It’s a different beast entirely, but it offers a compelling investment opportunity driven by powerful social and economic shifts. Think of it as a major segment of the broader demand for warehouse storage, but with its own unique flavour.

So, what's fuelling all this growth? It comes down to a few key trends. For starters, our urban living spaces are getting smaller, pushing people to find somewhere else to keep their personal belongings. At the same time, the boom in small e-commerce businesses has created a massive need for flexible, scalable inventory space that a stuffy, long-term warehouse lease just can't provide.

This unique customer base means the physical setup is miles away from your typical logistics hub. To succeed here, you need specialised infrastructure.

Unique Solutions for a Unique Market

Self-storage facilities aren't just empty warehouses with a new sign. They are purpose-built environments designed from the ground up for public access and top-notch security. The core components look nothing like what you’d find in a building designed for palletised goods; instead, the focus is all on individual, secure units.

Key infrastructure includes:

- Partitioned Steel Units: These are the backbone of any facility. They create the individual lockers and rooms of various sizes that cater to a wide range of customer needs.

- Container Storage: Offering external, drive-up container units gives customers a robust, convenient option for storing bulkier items like furniture or even vehicles.

- Robust Security Systems: High-definition CCTV, individually alarmed units, and controlled gate access aren't just nice-to-haves. They're fundamental for building the trust that keeps customers coming back.

- Access Control Technology: Modern facilities are ditching old-school keys for automated systems like keypads or mobile apps. This provides customers with secure, 24/7 access, which is a huge selling point.

This customer-facing model puts a much bigger emphasis on technology and user experience, setting it worlds apart from business-to-business warehousing.

The self-storage operational model is leaner and more automated than traditional warehousing. With lower daily staffing needs and a focus on customer-facing tech for rentals and access, it offers a distinct path to generating strong, consistent rental returns.

To really get the most out of day-to-day operations and maximise returns, checking out the best property management apps can give you a significant edge.

A Compelling UK Investment

The UK self-storage market just keeps showing remarkable resilience and growth, making it an incredibly attractive prospect for developers. The sector is defined by high demand and healthy rental yields, all propped up by a steadily growing customer base.

Recent industry data paints a very clear picture of this strength. As of 2024, the UK is home to over 2,900 self-storage sites. Together, they offer a combined 64.3 million square feet of space—that's a 7.2% increase from the previous year. Even with a slight dip in occupancy, the sector’s annual turnover shot past £1.2 billion, with average rental returns climbing by 6% to £29.13 per square foot. These aren't just numbers; they highlight a robust and expanding market. You can dive into the complete analysis in the UK Self Storage Annual Report from Cushman & Wakefield.

For developers, this data signals a clear opportunity. By getting to grips with the specific needs of this market—from partitioned units to advanced security—you can create highly profitable assets. For anyone seriously considering this venture, understanding the key steps is crucial. Our guide on seeing self-storage as a business offers some valuable insights into planning and launching a successful facility.

Turning Your Storage Investment Into Profit

So, you’ve got the blueprint. You’ve planned the layout, picked the systems, and navigated the regulations. Now for the most important part: turning all that hard work into a profitable asset.

This is where the rubber meets the road, connecting your technical decisions to real financial outcomes. After all, the big question for any developer is simple: how does this investment actually pay off? A smart storage solution isn't just an expense; it’s the engine that drives your return.

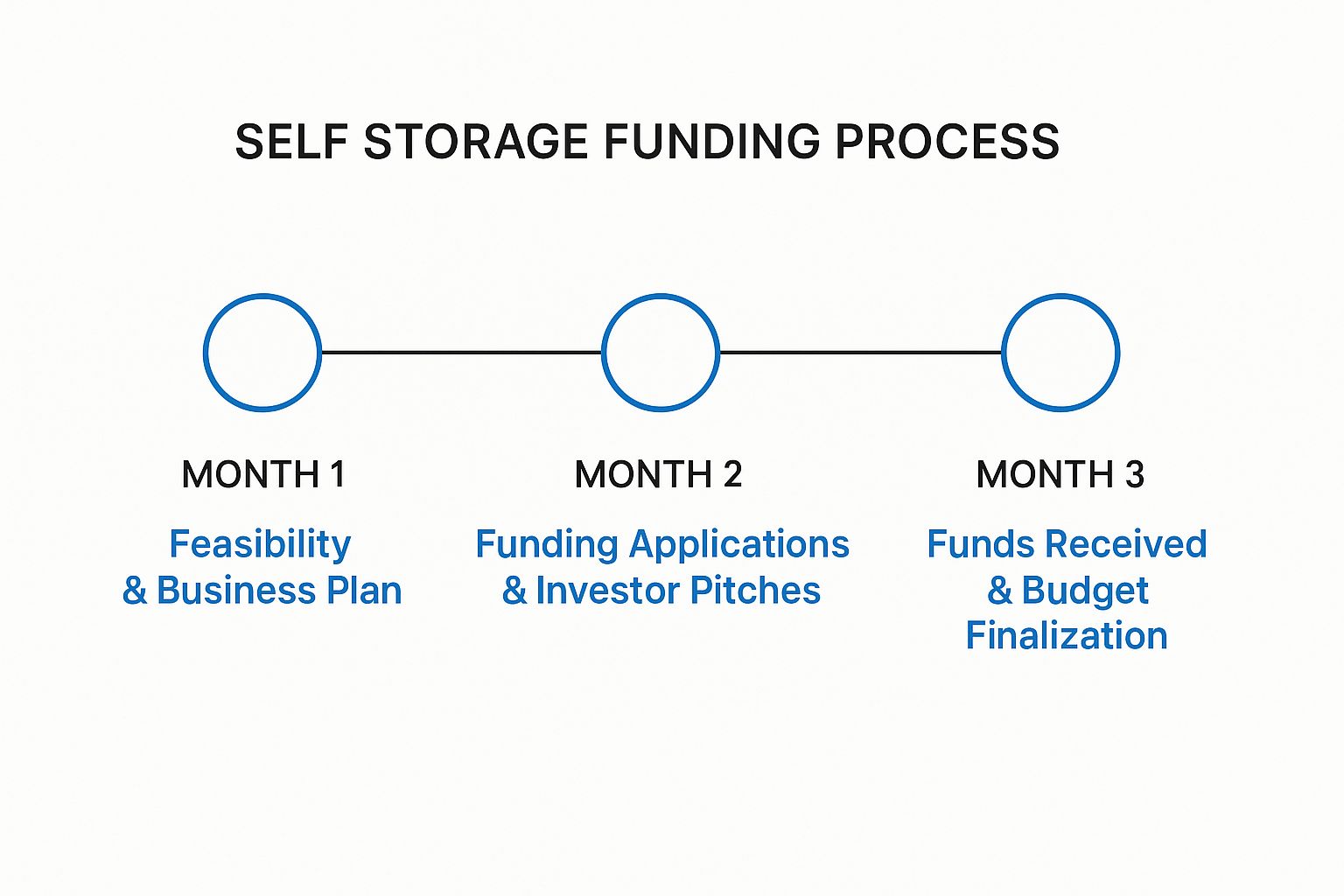

Before you can even start counting the profits, you need to get the project off the ground. That means securing the right funding without tying up all your capital reserves.

Understanding Your Financing Options

There are a few well-trodden paths for funding your warehouse or self-storage solutions, and each has its own set of pros and cons. The best choice really boils down to your business's current financial health and your long-term goals.

Here are the most common routes:

- Asset Finance: This is a popular one. You essentially borrow against the value of the equipment you’re buying, like the racking or a new mezzanine floor. The loan is secured by the assets themselves, which can make it easier to obtain.

- Commercial Loans: Think of this as the traditional bank loan. You get a lump sum to fund the project and pay it back over a set period. If you’ve got a solid business case, you can often lock in some competitive interest rates.

- Leasing: Instead of buying everything outright, you can lease the equipment for a fixed term. This keeps your initial spending low and often wraps maintenance costs into the deal. The catch? You won’t own the assets when the lease is up.

Each option impacts your cash flow, ownership, and flexibility differently. It pays to crunch the numbers on all of them to make sure your project starts on a solid financial footing.

Calculating Your Return on Investment

Once the funding is sorted, the focus shifts to proving the project's worth. This is where Return on Investment (ROI) comes in. It’s not just about making sure the numbers add up; it’s about showing exactly how much new value your optimised facility is creating.

ROI gives you the clear, data-backed evidence you need to justify the initial spend. It changes the conversation from "How much does it cost?" to "How much will it make us?" – a crucial shift for getting everyone on board.

The basic formula is straightforward enough: weigh the total cost against the net profit it generates. The real art, though, is in spotting and measuring all the gains accurately. These benefits go way beyond just the monthly rental income; they often include massive operational savings.

To build a truly compelling business case, you need to put a number on gains like:

- Increased Storage Density: A smarter layout equals more rentable square metres. It’s a direct and immediate boost to your revenue potential.

- Improved Picking Efficiency: Better workflows mean less time spent per order. Over a year, those saved labour costs really add up.

- Reduced Operational Errors: An organised system cuts down on mistakes, which means fewer costly returns or inventory write-offs.

When you can attach real figures to these benefits, you create an undeniable argument for the investment. It clearly shows how a strategic warehouse storage solution translates directly into long-term, sustainable profit.

Your Top Warehouse Storage Questions Answered

When you're in the thick of a warehouse development project, the same practical questions tend to pop up again and again. Getting straight answers can save you a world of time, money, and headaches down the line. It's about making sure your storage solutions are built on a solid foundation of smart choices.

Let's tackle some of the most common hurdles that developers and operators face, bridging that gap between high-level strategy and what actually happens on the ground.

Should I Go for New or Used Racking?

This is a classic dilemma, and it really comes down to balancing your initial budget against long-term reliability. Used racking can look incredibly tempting, sometimes offering savings of up to 40% compared to new. That's a figure that makes anyone on a tight budget sit up and take notice.

But stepping onto the used racking path means you need to have your eyes wide open. You're giving up the manufacturer's warranty and any real certainty about its history. You have no way of knowing if it's been overloaded, bashed by a forklift, or poorly repaired in a past life, all of which could seriously compromise its structural integrity.

Choosing used racking might slash your upfront costs, but it shifts all the responsibility for safety and compliance squarely onto your shoulders. You'll need to be ready to bring in a qualified engineer for a thorough structural assessment to make sure it's fit for purpose and meets current UK regulations.

New racking, on the other hand, is a clean slate. It arrives with a full warranty, a guarantee that it meets the latest safety standards, and complete peace of mind. Yes, the initial cheque you write will be bigger, but the long-term value you get from its durability and reduced risk is often an investment that pays for itself.

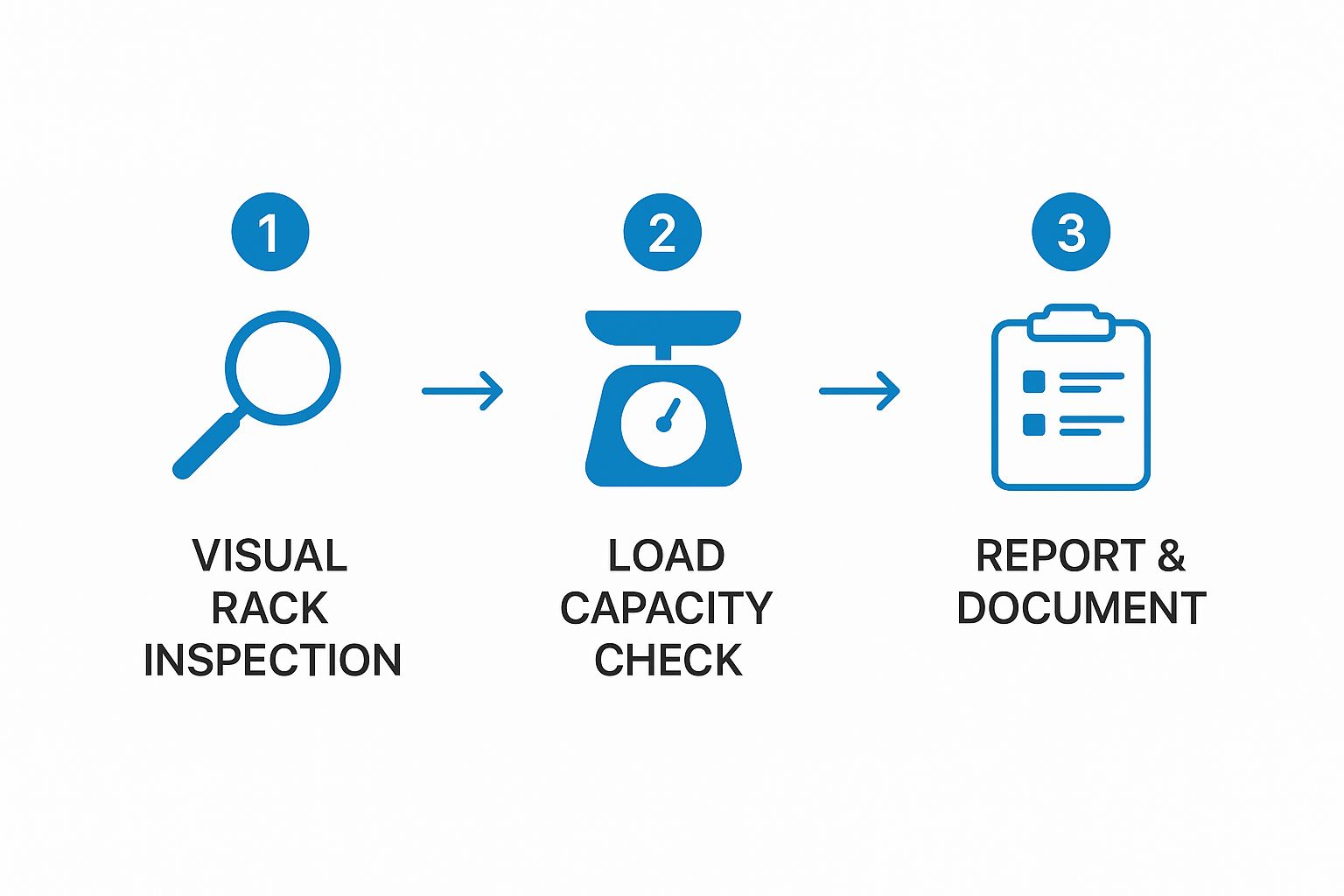

What Are the Key UK Safety Regulations I Need to Know?

In the UK, warehouse safety isn't just a good idea—it's the law. The Health and Safety Executive (HSE) enforces a strict set of regulations, and compliance is non-negotiable. For anyone developing a new facility, getting these rules right from day one is fundamental.

Here are three critical areas you absolutely have to get right:

- Regular Inspections: Your racking needs to be inspected regularly by someone who is technically competent. The gold standard is to have an annual inspection carried out by a SEMA (Storage Equipment Manufacturers' Association) Approved Racking Inspector.

- Visible Load Notices: Every single racking installation must have clear, easy-to-read load notices. These signs need to spell out the maximum safe working loads for both the beams and the entire bay to prevent dangerous overloading.

- Rack Protection: High-traffic areas demand solid rack protection. It’s mandatory to install things like column guards and end-of-aisle barriers to shield vulnerable racking uprights from forklift collisions—one of the biggest causes of racking failure.

How Can I Mix Technology with My Traditional Storage?

You don't need to rip everything out and start again with a multi-million-pound automated system to bring your warehouse into the 21st century. The smart move is to integrate modern tools with your traditional warehouse storage solutions to get a major efficiency boost without breaking the bank. Think enhancement, not a total replacement.

A Warehouse Management System (WMS) is the perfect place to start. This software essentially becomes the brain of your operation, helping you get a grip on inventory tracking, order picking, and making the best use of your space. Pair it with simple hardware like barcode scanners, and you’ll slash human error while gaining real-time visibility into your stock levels.

Even entry-level automation can make a huge difference. Something as simple as installing conveyors to move goods from your packing stations to the shipping zone can cut down on how much your team has to walk, speeding up dispatch times considerably.

Ready to design a self-storage facility that maximises your return on investment? The expert team at Partitioning Services Limited specialises in end-to-end project management, from initial design and compliance to manufacturing and installation. Explore our turnkey self-storage solutions at https://psllimited.co.uk.

Understanding cost of self storage units: A Quick Guide

When you're trying to figure out the cost of self storage units in the UK, you’ll find prices can range anywhere from £50 to £250 a month. A lot like booking a hotel, the final price really comes down to a few key things: the unit's size, where it’s located, and whether you need special features like climate control. A small, simple unit in a quiet town will always be easier on the wallet than a large, high-security space in central London.

Breaking Down the Average Cost of Self Storage Units

So, what should you actually expect to pay? It helps to understand that storage prices aren't just plucked out of thin air. They're a direct reflection of the value, security, and convenience you're getting. Think of it as a spectrum: at one end, you have basic, no-frills storage, and at the other, premium spaces with all the bells and whistles. Your final bill will land somewhere in between, depending on what you need.

A good rule of thumb across the UK is to expect rental rates somewhere between £27 and £30 per square foot per year. But take that figure with a grain of salt, because location is a massive factor. In London’s most competitive postcodes, it’s not unusual to see that number climb above £35 per square foot. This “London premium” is one of the biggest drivers of cost you’ll come across.

A Quick Glance at Monthly Costs

To make things a bit clearer, let's look at what you might pay each month. The most straightforward factor is size—the more space you need, the higher the rent. It’s that simple.

- Small Units (25-50 sq ft): These are perfect for stashing boxes, a few pieces of small furniture, or a student's belongings over the summer. They're your most budget-friendly choice.

- Medium Units (75-150 sq ft): Got the contents of a one or two-bedroom flat? A medium unit is usually the sweet spot, making it a popular option for people in the middle of a move.

- Large Units (200+ sq ft): If you're storing the contents of an entire house or need space for business inventory, you'll be looking at a large unit.

For an even more detailed look at what to expect, you can find out how much storage costs monthly and compare your options.

Here’s a quick table to give you a rough idea of monthly rental costs, showing just how much of a difference being in the capital can make.

Estimated Monthly Self Storage Costs in the UK

| Unit Size (sq ft) | What It Holds (Example) | Average Monthly Cost (Outside London) | Average Monthly Cost (London) |

|---|---|---|---|

| 25 sq ft | Student belongings, 30-40 boxes | £40 - £70 | £70 - £110 |

| 50 sq ft | Contents of a studio flat | £70 - £110 | £110 - £160 |

| 100 sq ft | Contents of a 1-2 bedroom flat | £120 - £180 | £180 - £250 |

| 150 sq ft | Contents of a 2-3 bedroom house | £170 - £240 | £240 - £350 |

| 200 sq ft | Contents of a 4-bedroom house | £220 - £300+ | £320 - £450+ |

As you can see, the price gap widens significantly as the units get bigger. It really pays to know exactly how much space you need before you commit.

Decoding Your Self Storage Price Tag

Figuring out the final cost of a self-storage unit is a bit like playing with the dials on a mixing board. Every choice you make, from the unit's size to its exact spot in the building, turns a specific dial up or down. There's no single fixed price; it's a dynamic figure shaped by a handful of key variables. Once you get a grip on these factors, you can make smarter trade-offs and strike the perfect balance between what you need and what you want to spend.

Naturally, a massive, ground-floor unit in a busy city centre is going to push all those dials to the max, landing you with a premium price tag. On the flip side, a smaller unit tucked away on an upper floor in a more rural spot will keep the dials low, offering a much more budget-friendly option. Let's break down the main components that make up your monthly storage bill.

Unit Size: The Most Obvious Price Driver

The biggest factor dictating the cost of self storage units is its physical size. Simple, really. Just like buying property, you're paying for the space you use. Facilities price their units per square foot, so a 100 sq ft unit is always going to cost more than a 50 sq ft one at the same site.

Getting the size right is crucial. If you rent a unit that’s too big, you’re just throwing money away on empty space every single month. But if you underestimate, you’ll end up with a frustratingly cramped unit, probably forcing you to upgrade later anyway. The goal is to find that "Goldilocks" size—not too big, not too small, but just right.

The infographic below gives you a clear visual breakdown of how unit size stacks up against average UK prices.

It clearly shows the direct link between space and price. As you go from storing a few boxes to the entire contents of a house, the cost climbs accordingly.

Location, Location, Location

That old real estate saying is just as true for self-storage. Where the facility is located plays a massive part in its pricing. A site in a prime city location with high property values and tons of demand will inevitably charge more than one out in the suburbs or the countryside.

It all boils down to convenience and accessibility:

- City Centre Facilities: These demand the highest prices. They're close to densely populated residential and business areas, and you're paying a premium for the convenience of not having to travel far.

- Suburban Facilities: Situated just outside the main city hubs, these often offer a better balance on cost. They’re still easy enough to get to but benefit from lower overheads.

- Rural Facilities: These will typically give you the lowest prices, but you’ll have to factor in a longer journey every time you need to access your things.

Simply by shifting your search a few miles outside a major city, you can often find significantly lower monthly rates for the exact same size unit. It's a classic trade-off: travel time versus cost savings.

Floor Level and Accessibility

Even within the same building, not all units of the same size are created equal. Their specific location inside the facility also moves the price dial.

- Ground Floor Units: These are the most desirable because they’re the most convenient. You can often drive right up to the door or at least move things in and out without battling stairs or lifts. That ease of access comes at a premium.

- Upper Floor Units: Units on higher levels are almost always cheaper. Yes, you’ll have to use a lift or stairs, but the cost savings can be substantial. It's an excellent choice if you don’t need to be popping in and out all the time.

At the end of the day, the final price on your storage quote is a blend of all these factors. By understanding how each one nudges the price up or down, you can strategically pick a unit that gives you the right space, in the right place, for the right price.

How Special Features Affect Your Final Bill

While the size of the unit and its location are the big-ticket items, it’s the special features that often push the final price up. These are the premium options that add layers of convenience, protection, and frankly, peace of mind.

Think of it like buying a car. The basic model will get you from A to B just fine, but extras like heated seats or a better sound system make the journey a whole lot more pleasant. In self-storage, these extras aren’t just about comfort; sometimes, they're absolutely essential.

The Non-Negotiable Case for Climate Control

For certain items, climate control isn’t a luxury—it's a necessity. A standard unit will keep your things dry, but a climate-controlled one goes a step further, maintaining a stable temperature and humidity level all year round.

Imagine storing your grandmother’s antique wooden dresser or a cherished vinyl record collection in a damp, unheated garage through a classic British winter. The constant shifts in temperature and moisture would wreak havoc, causing warping, mould, and permanent damage. A climate-controlled unit is your best defence against that kind of environmental assault.

This feature is critical for storing anything sensitive to extreme heat, cold, or humidity. The extra cost, which can bump up your monthly bill by 20% to 50%, is a small price to pay compared to the heartbreak and expense of replacing your treasured possessions.

You should seriously consider a climate-controlled unit if you’re storing:

- Wooden or leather furniture, which can crack, warp, or rot in fluctuating conditions.

- Electronics and media like computers, TVs, vinyl records, and DVDs.

- Important documents and photos that can degrade or stick together when damp.

- Artwork and antiques whose value relies on them staying in pristine condition.

Enhanced Security Measures

Beyond a simple padlock, many modern facilities offer advanced security features for an extra layer of protection. These upgrades are especially important if you’re storing high-value personal goods or business inventory.

High-tech security isn’t just about stopping thieves; it’s about having a verifiable record of access and getting immediate alerts if something’s wrong. To get a real sense of how these features affect the bottom line, it's worth delving into understanding business security system costs and the value they deliver.

Common security upgrades include:

- 24/7 CCTV Surveillance: Constant monitoring of all corridors, entrances, and exits.

- Individual Unit Alarms: An alarm that sounds if your specific unit is opened without authorisation.

- Gated Electronic Access: A system requiring a personal code just to get onto the facility grounds.

Every decent facility offers basic security, but these enhanced features provide an extra guarantee. The peace of mind that comes from knowing your unit is individually alarmed and watched around the clock can easily justify a small price increase.

Drive-Up Access and Other Conveniences

Finally, there are the features designed to simply make your life easier. The most popular is drive-up access, which lets you park your car or van right at your unit’s door. This is a game-changer if you’re frequently loading or unloading heavy, bulky items.

Because of its ground-floor location and unmatched convenience, this feature typically costs more than an equivalent indoor unit. It might seem like a small detail, but it can save you a huge amount of time and physical effort with every single visit. By weighing these special features against your actual needs, you can work out which ones are worth the extra cash and which are just nice-to-haves.

Choosing Between Indoor Units and Outdoor Containers

When you’re looking at self-storage, one of the first big decisions is whether to go for a classic indoor unit or a rugged outdoor container. This choice is a major factor in the cost of self storage units, and it also dictates the level of protection and convenience you’ll get.

Think of it like parking a car: you could choose a secure, multi-storey car park or a dedicated spot in an open-air lot. Both get the job done, but they meet different needs and come with very different price tags.

Indoor units are exactly what they sound like—they’re housed inside a larger building, often with multiple floors you can get to via lifts. This setup provides a sheltered environment, shielding your belongings from direct exposure to rain, snow, and harsh sunlight. It's the go-to option for anything that needs a stable, controlled atmosphere.

On the other hand, outdoor containers are typically large steel boxes that you can drive right up to. They’re built tough and designed for easy access, making them incredibly handy for loading and unloading bulky items straight from a vehicle.

The Case for Protected Indoor Units

The biggest draw for an indoor unit is protection. Being inside a building adds an extra layer of security and insulates your possessions from the unpredictable British weather. This is especially true for facilities offering climate-controlled options, which you’ll almost exclusively find indoors.

These units are the ideal home for valuable or sensitive items, such as:

- Antique wooden furniture that could warp or crack in changing temperatures.

- Electronics and important documents that are easily damaged by humidity.

- Soft furnishings, clothing, and mattresses that might attract mould in damp conditions.

Because of this superior protection and the added security of being inside a locked building, indoor units usually come with a slightly higher monthly cost. You’re really paying for peace of mind.

The Appeal of Accessible Outdoor Containers

Outdoor containers, often called drive-up units, offer unbeatable convenience and are usually a more wallet-friendly choice. Their main selling point is the ability to park your car or van right at the door, which makes moving heavy or awkward items a whole lot easier.

This style of storage is really taking off. While around 61% of self storage units are still internal, the other 39% are container-based—and that number is growing fast. To see the full industry picture, you can discover more insights in the UK self storage report for 2025.

This growth shows just how practical they are for both personal and business use, especially for anyone who needs to get to their stuff frequently. Understanding how external garage units maximise space also reveals why they’re such a cost-effective choice for both facility owners and renters.

Outdoor containers are perfect for storing robust items like garden machinery, business stock, tools, or even vehicles. Their tough steel construction provides excellent security against theft and physical damage, even if they don't offer the same level of climate stability as indoor units.

To help you weigh your options, here’s a straightforward comparison of the two.

Internal Units vs. Container Storage: A Head-to-Head Comparison

Choosing between an internal unit and an external container really comes down to what you’re storing and how often you need to access it. An internal unit offers a premium, protected environment, whereas a container prioritises convenience and value.

| Feature | Internal Storage Unit | External Storage Container |

|---|---|---|

| Best For | Furniture, electronics, documents, antiques | Tools, vehicles, business stock, garden equipment |

| Accessibility | Requires moving items through hallways/lifts | Drive-up access for easy loading/unloading |

| Protection | Excellent protection from elements; climate control available | Good protection from elements, but no climate control |

| Security | Multi-layered (gated access, building entry, unit lock) | Highly secure (tough steel, high-security lock) |

| Typical Cost | Generally higher due to amenities | Often more affordable per square foot |

Ultimately, both are great solutions. Your final decision will depend on balancing the need for protection against the desire for easy access and a lower price point.

Smart Storage Strategies for Your Business

We usually think of self-storage in personal terms—a place to stash furniture during a move or keep sentimental bits and bobs that just won’t fit in the house. But it's also a powerful, flexible tool for businesses wanting to grow without getting tangled up in the rigid, expensive world of traditional commercial leases. For many companies, a storage unit isn't just extra space; it's a strategic asset.

Think of a normal warehouse or office lease like a pricey annual gym membership you have to pay for upfront. You're locked in, whether you use it every day or not. A self-storage unit, on the other hand, is like a pay-as-you-go gym pass. It gives you the freedom to scale your space up or down as your business changes, all without the headache of long-term contracts, massive deposits, business rates, or surprise utility bills.

This kind of adaptability is a complete game-changer for small and medium-sized businesses, offering a low-overhead way to manage physical stock and operations.

How Businesses Leverage Self Storage

The ways businesses use commercial storage are incredibly diverse, often turning a simple unit into a central hub. It’s a versatile tool that can be moulded to fit all sorts of operational models, from online retail to the skilled trades.

Here are a few real-world examples of how it works:

- E-commerce Inventory Hub: An online seller of handmade crafts can use a unit to keep products, packaging, and shipping supplies organised. This clears the clutter from their home and lets them manage stock efficiently as orders ebb and flow.

- Secure Document Archiving: A solicitor's office or accounting firm can store years of client files and financial records in a secure, climate-controlled unit. This frees up prime office space while ensuring they stay compliant with data retention laws.

- Tradesperson's Base of Operations: A plumber or electrician can use a drive-up container to securely store their tools, equipment, and materials. It becomes a central depot they can access daily—far more cost-effective than renting a dedicated workshop.

A Launchpad for Growth

This move towards using storage for business isn't just a niche trend. In fact, a whopping 24% of self-storage users are now running a business from their units, which shows just how much the industry has evolved. You can read the full report on UK self storage trends to see how commercial use is taking shape.

For a startup or sole trader, a storage unit can be the perfect incubator. It offers a professional base of operations without the financial gamble of a five-year lease. That frees up capital to be ploughed back into the business—for marketing, developing new products, or hiring staff.

This approach gives entrepreneurs the power to test their business ideas and scale up at a sensible pace. By understanding how to use self storage as a business, owners can build a more resilient and agile company from the ground up, turning the cost of a unit into a smart investment rather than just another expense.

Proven Tips to Reduce Your Storage Costs

Knowing what drives the cost of self storage units is one thing, but actually using that knowledge to get the best deal is where the real savings happen. With a few clever strategies, you can bring your monthly bill down significantly without compromising on the space or security you need. It’s all about being methodical and making smart choices before you sign on the dotted line.

Think of it like doing your weekly food shop on a budget. You wouldn’t just wander in and grab the first things you see. You’d compare brands, look for special offers, and stick to your list. Applying that same mindset here will ensure you get maximum value for every pound spent.

Get the Size Right from the Start

The single most effective way to save money is to avoid paying for empty air. It’s a classic mistake: renting a unit that’s far too large for your needs, and it gets expensive fast. Before you even start comparing prices, take a proper inventory of every single item you plan to store.

Most facilities have online size calculators, or you can speak directly to the managers for an accurate estimate. Getting this right from day one means you only rent the square footage you actually require, preventing those unnecessary costs from creeping in. This is the cornerstone of any cost-effective storage plan.

Your goal is to pack the unit efficiently, leaving just enough of a walkway to get to your things. A well-organised, smaller unit is always cheaper than a half-empty larger one.

Be Smart About Location and Timing

Just like property prices, storage rates are heavily swayed by location and seasonal demand. A bit of flexibility here can translate into big savings.

- Look Beyond the City Centre: Facilities located just a few miles outside a major urban hub often have significantly lower rates. If you don't need daily access, that extra travel time is a brilliant trade-off for a cheaper monthly bill.

- Book During the Off-Season: Demand for storage usually spikes in the summer months when everyone is moving house. If you can hold off, try renting in the autumn or winter when facilities might be running better deals to fill their units.

- Snag Online-Only Offers: Many storage companies feature exclusive discounts on their websites that you won’t get if you just walk in off the street. Always check online first to lock in the best introductory rate.

Declutter and Pack Like a Pro

Finally, how you prepare your belongings can make a real difference to your bottom line. Before you even think about packing a box, be ruthless with your decluttering. Sell, donate, or get rid of anything you genuinely no longer need. The less you have to store, the smaller—and cheaper—your unit can be.

When it is time to pack, be strategic. Use uniform-sized boxes that you can stack easily, and make sure they’re filled to the top so they don’t get crushed. Dismantling furniture like bed frames and tables is a must for saving precious floor space. For businesses aiming to fully utilise vertical space, learning about the benefits of commercial mezzanine floors can offer some great inspiration for stacking and organising efficiently. By packing smartly, you might even discover you can fit everything into a smaller unit than you first thought.

Still Have a Few Questions About Storage Unit Costs?